An accumulator in automotive braking systems is a crucial component used to store hydraulic energy under pressure. This device typically consists of a gas-filled chamber separated from brake fluid by a piston or diaphragm, allowing it to maintain consistent brake pressure during operation. By providing a backup supply of hydraulic fluid, the accumulator ensures effective braking performance even during sudden pressure drops. In vehicles equipped with anti-lock braking systems (ABS) or hybrid hydraulic brakes, accumulators are essential for maintaining brake responsiveness and safety. The accumulator's ability to deliver instant pressure helps stabilize the braking system and reduce wear on other components. Data from automotive manufacturers highlight that accumulator use improves brake system reliability and driver control in emergency braking conditions.

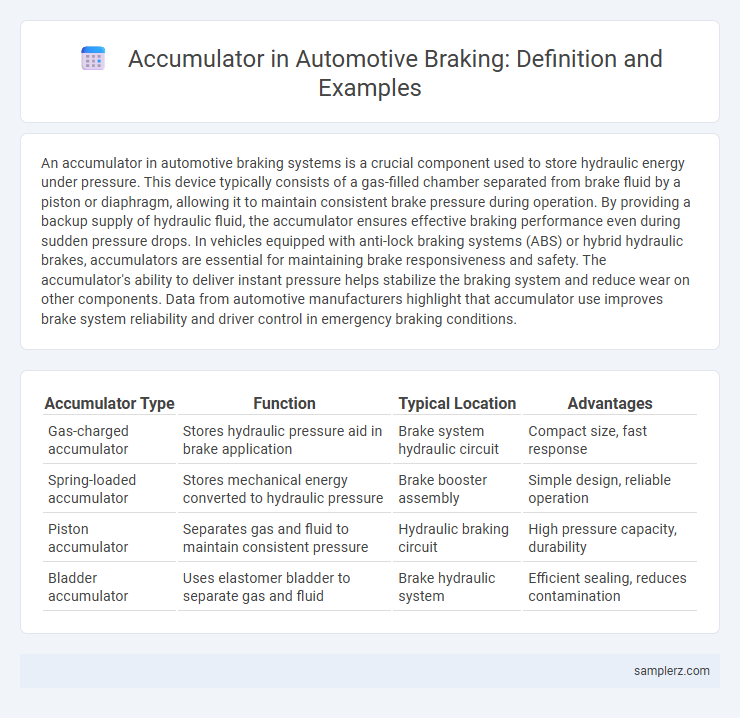

Table of Comparison

| Accumulator Type | Function | Typical Location | Advantages |

|---|---|---|---|

| Gas-charged accumulator | Stores hydraulic pressure aid in brake application | Brake system hydraulic circuit | Compact size, fast response |

| Spring-loaded accumulator | Stores mechanical energy converted to hydraulic pressure | Brake booster assembly | Simple design, reliable operation |

| Piston accumulator | Separates gas and fluid to maintain consistent pressure | Hydraulic braking circuit | High pressure capacity, durability |

| Bladder accumulator | Uses elastomer bladder to separate gas and fluid | Brake hydraulic system | Efficient sealing, reduces contamination |

Introduction to Accumulators in Automotive Braking

Automotive braking systems utilize accumulators to store hydraulic energy, enhancing brake response and safety by maintaining consistent pressure during sudden stops. These accumulators typically contain a gas-charged bladder or piston that compresses fluid under pressure, enabling rapid brake actuation and reducing pedal effort. Modern vehicles integrate hydraulic accumulators within ABS or ESP modules to improve braking stability and performance under diverse driving conditions.

Role of Accumulators in Brake Systems

Accumulators in automotive brake systems store hydraulic pressure to provide consistent and immediate brake response, especially during sudden stops or system pressure drops. They enhance safety by maintaining brake force when engine power is insufficient or the primary hydraulic source fails. This ensures reliable braking performance and reduces the risk of brake system failure under critical conditions.

Types of Accumulators Used in Braking Applications

In automotive braking systems, hydraulic accumulators such as bladder, piston, and diaphragm types store pressurized fluid to maintain consistent brake pressure, ensuring reliable performance during sudden stops. Bladder accumulators use a flexible rubber bladder to separate gas and fluid, providing quick response and compact design ideal for passenger vehicles. Piston accumulators offer high durability and are commonly utilized in heavy-duty braking systems to handle higher pressure demands, while diaphragm accumulators feature a flexible membrane, offering precise pressure control in specialized braking applications.

Hydraulic Accumulators: Working Principle and Functions

Hydraulic accumulators in automotive braking systems store pressurized fluid to maintain consistent brake pressure and improve response time during sudden stops. These devices use a gas-charged bladder or piston to absorb hydraulic fluid under pressure, releasing it when needed to compensate for pressure fluctuations and enhance braking performance. By stabilizing hydraulic pressure, accumulators prevent brake fade and increase system reliability in advanced anti-lock braking systems (ABS) and electronic stability control (ESC).

Electro-Hydraulic Braking Systems and Accumulator Integration

Electro-hydraulic braking systems integrate accumulators to store pressurized hydraulic fluid, ensuring rapid brake response and enhanced safety. These accumulators maintain consistent brake pressure during system demand variations, improving overall braking performance and reducing pedal effort. Incorporating high-pressure gas-charged accumulators helps stabilize braking force, contributing to efficient energy management and system reliability.

Examples of Accumulator Use in ABS Systems

In automotive braking, accumulators in ABS systems store hydraulic pressure to ensure rapid brake response during sudden stops. For example, Bosch ABS modules use accumulators to maintain consistent brake fluid pressure, preventing wheel lockup in emergency braking scenarios. Similarly, Continental ABS units employ piston accumulators to balance pressure fluctuations, enhancing vehicle stability and control.

Accumulators in Regenerative Braking for Hybrid and EVs

Accumulators in regenerative braking systems for hybrid and electric vehicles store hydraulic energy generated during braking, improving energy efficiency and reducing wear on mechanical components. These devices capture excess kinetic energy, converting it into hydraulic pressure that can be reused to assist in vehicle acceleration or braking, enhancing overall system responsiveness. Advanced accumulators optimize energy recovery by stabilizing brake pressure and enabling smoother transitions between regenerative and friction braking modes.

Safety Benefits of Accumulators in Braking Performance

Hydraulic accumulators in automotive braking systems store pressurized fluid to ensure immediate brake response during sudden stops, significantly enhancing vehicle safety. They maintain consistent braking pressure, reducing the risk of brake failure and improving overall control in emergency situations. By stabilizing hydraulic pressure, accumulators contribute to shorter stopping distances and increased occupant protection.

Common Failures and Maintenance of Brake Accumulators

Brake accumulators in automotive braking systems often face common failures such as diaphragm rupture, gas leakage, and loss of pre-charge pressure, which compromise braking efficiency and safety. Regular maintenance includes inspecting the accumulator for cracks, ensuring the gas pre-charge is at the specified pressure, and replacing worn or damaged components to prevent hydraulic fluid contamination. Timely servicing of brake accumulators enhances system reliability, reduces the risk of brake failure, and extends the overall lifespan of the braking system.

Future Trends in Accumulator Technology for Braking Systems

Advanced accumulator technology in automotive braking systems is increasingly integrating electro-hydraulic mechanisms to enhance energy efficiency and responsiveness. Innovations in smart materials and IoT connectivity enable real-time monitoring and predictive maintenance, improving safety and system durability. Research into compact, lightweight accumulators promises to reduce vehicle weight, contributing to overall fuel efficiency and performance in next-generation braking systems.

example of accumulator in braking Infographic

samplerz.com

samplerz.com