A detent in an automotive shifter refers to a mechanical feature that provides tactile feedback and precise positioning for gear selection. This mechanism often consists of a spring-loaded ball or pin that fits into notches or grooves on the shift lever or gate. The detent ensures that the shifter stays securely in a chosen gear, preventing accidental movement and enhancing driving safety. In automatic transmissions, the detent plays a crucial role in maintaining the alignment of the shift lever with the transmission's gearset. It works by resisting unintended shifts and giving drivers a clear sensation of each gear position. Many modern vehicles incorporate detent systems made from durable materials to withstand repeated use and maintain optimal performance over time.

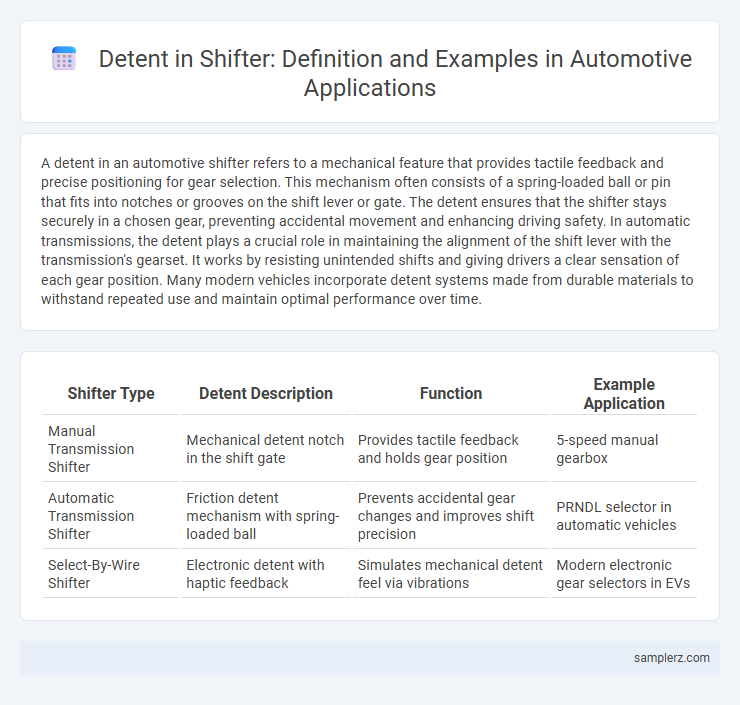

Table of Comparison

| Shifter Type | Detent Description | Function | Example Application |

|---|---|---|---|

| Manual Transmission Shifter | Mechanical detent notch in the shift gate | Provides tactile feedback and holds gear position | 5-speed manual gearbox |

| Automatic Transmission Shifter | Friction detent mechanism with spring-loaded ball | Prevents accidental gear changes and improves shift precision | PRNDL selector in automatic vehicles |

| Select-By-Wire Shifter | Electronic detent with haptic feedback | Simulates mechanical detent feel via vibrations | Modern electronic gear selectors in EVs |

Understanding the Role of Detents in Automotive Shifters

Detents in automotive shifters provide tactile feedback and precise positioning, ensuring secure gear engagement and preventing accidental shifts. These mechanical notches enhance driver control by creating distinct click points corresponding to each gear position, improving overall shift accuracy and safety. Properly designed detents contribute to smoother gear transitions and reduce wear on transmission components.

Key Functions of Shifter Detents in Modern Vehicles

Shifter detents provide precise tactile feedback and secure gear positioning, preventing accidental shifts and enhancing driver control. These mechanical or electronic detents ensure smooth transitions between gears, contributing to vehicle safety and drivability. Modern vehicles rely on shifter detents to improve transmission response and optimize shifting performance under various driving conditions.

Common Types of Detents Used in Gear Shifters

Common types of detents used in automotive gear shifters include ball detents, spring-loaded detents, and cam detents. Ball detents provide precise positioning by using a spring-loaded ball that fits into notches on the shift lever, ensuring secure gear engagement. Spring-loaded detents offer smooth tactile feedback by compressing a spring as the shifter moves, while cam detents utilize a cam mechanism to create defined gear positions for reliable shifting performance.

Mechanical Detent Mechanisms: How They Work

Mechanical detent mechanisms in automotive shifters use notched plates or grooves paired with spring-loaded balls to create tactile feedback and hold the gear lever firmly in the selected position. This system ensures precise gear engagement by providing resistance that the driver can feel, preventing unintentional gear slippage. The detent's design balances secure positioning with smooth shifting, enhancing both safety and driving experience.

Electronic Versus Mechanical Detents: A Comparison

Electronic detents in automotive shifters provide precise gear positioning through sensors and actuators, enhancing shift accuracy and reducing mechanical wear compared to traditional mechanical detents, which rely on physical notches and springs for tactile feedback. Mechanical detents offer simplicity and reliability but may suffer from increased wear and less consistent shift quality over time. Electronic systems enable adaptive shifting behavior and integration with advanced driver assistance systems, improving overall driving experience and vehicle performance.

Real-World Examples of Shifter Detent Applications

In automotive gear shifters, detents provide tactile feedback by locking the shifter into predefined positions, enhancing driver control and safety. A common example is the manual transmission gate, where detent notches prevent accidental gear changes and ensure precise engagement of each gear. High-performance vehicles often utilize adjustable detent systems for customizable shift feel and improved responsiveness.

Advantages of Using Detents in Transmission Shifters

Detents in transmission shifters provide precise gear position feedback, enhancing driver confidence and control during gear changes. They reduce the risk of mis-shifting by ensuring positive engagement into each gear, which improves overall drivetrain reliability and longevity. The tactile sensation from detents also contributes to smoother, more consistent shifting performance in both manual and automatic transmissions.

Signs of Detent Wear or Failure in Automotive Shifters

Signs of detent wear or failure in automotive shifters include increased gear slip, difficulty in maintaining gear position, and a loose or shaky gear lever. Worn detent mechanisms often cause abnormal noises such as clicking or grinding when shifting gears. These symptoms indicate compromised gear engagement and necessitate inspection or replacement to ensure safe and reliable vehicle operation.

How Detents Enhance Driver Safety and Gear Precision

Detents in automotive shifters provide tactile feedback and ensure precise gear engagement, minimizing the risk of accidental gear slips that could compromise driver safety. The mechanical resistance created by detents helps drivers confidently select the desired gear, enhancing control and reducing the likelihood of transmission errors during operation. This precise gear positioning contributes to smoother driving experiences and prevents potential drivetrain damage from improper shifting.

Maintenance Tips for Shifter Detent Longevity

Regularly lubricate the shifter detent mechanism with a high-quality, automotive-grade grease to reduce friction and prevent wear. Inspect the detent spring and ball for signs of corrosion or damage to ensure smooth gear engagement and precise shifting. Replace worn or damaged detent components promptly to maintain shifting accuracy and extend the longevity of the shifter assembly.

example of detent in shifter Infographic

samplerz.com

samplerz.com