Lapping in automotive valve maintenance refers to the precision process of grinding the valve seat and valve face together to create a perfect seal. This is achieved by applying an abrasive compound between the valve and its seat, then rotating the valve to ensure even wear and a tight fit. Proper lapping improves engine compression, reduces leakage, and enhances overall engine performance by ensuring optimal combustion chamber sealing. The lapping process is critical during engine rebuilds or valve replacements to ensure longevity and reliability of the valve system. Specialized tools like valve lapping sticks and fine grit compounds are used to achieve the desired surface finish. Effective valve lapping contributes to efficient fuel combustion, reduced emissions, and improved power output in automotive engines.

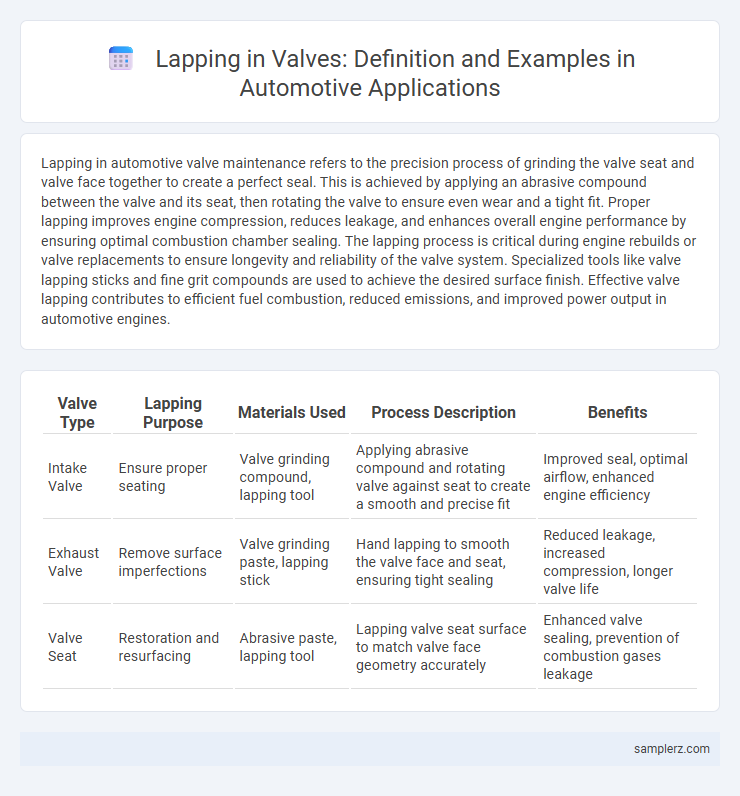

Table of Comparison

| Valve Type | Lapping Purpose | Materials Used | Process Description | Benefits |

|---|---|---|---|---|

| Intake Valve | Ensure proper seating | Valve grinding compound, lapping tool | Applying abrasive compound and rotating valve against seat to create a smooth and precise fit | Improved seal, optimal airflow, enhanced engine efficiency |

| Exhaust Valve | Remove surface imperfections | Valve grinding paste, lapping stick | Hand lapping to smooth the valve face and seat, ensuring tight sealing | Reduced leakage, increased compression, longer valve life |

| Valve Seat | Restoration and resurfacing | Abrasive paste, lapping tool | Lapping valve seat surface to match valve face geometry accurately | Enhanced valve sealing, prevention of combustion gases leakage |

Introduction to Valve Lapping in Automotive Engines

Valve lapping in automotive engines involves a precision process of grinding the valve face against the valve seat to ensure a perfect seal, enhancing combustion efficiency and preventing gas leaks. This technique uses abrasive compounds and rotational motion to smooth valve contact surfaces, critical for maintaining optimal engine compression and performance. Proper lapping reduces wear, extends valve life, and improves fuel economy in internal combustion engines.

What is Valve Lapping?

Valve lapping is a precision automotive process where abrasive compounds are used to smooth the valve surface and its corresponding seat, ensuring an airtight seal within the engine cylinder head. This technique enhances combustion efficiency by preventing gas leaks, reducing valve wear, and improving engine performance. Proper valve lapping is essential for maintaining optimal compression and extending the lifespan of engine components.

Importance of Valve Lapping for Engine Performance

Valve lapping ensures a precise seal between the valve and valve seat, enhancing engine compression and preventing combustion gas leaks. Proper lapping improves fuel efficiency, reduces emissions, and extends engine longevity by maintaining optimal valve seating. Regular valve lapping is crucial for high-performance engines seeking maximum power and reliability.

Common Tools Used for Valve Lapping

Common tools used for valve lapping include valve grinding compounds, typically silicon carbide or diamond paste, which are essential for creating smooth, precise valve seats. Lapping sticks or specialized lapping tools provide controlled pressure and movement to evenly wear the valve surface for optimal sealing. Precision inspection gauges measure the flatness and contact area to ensure proper valve seat alignment and engine performance.

Step-by-Step Valve Lapping Procedure

Valve lapping involves applying a fine abrasive compound to the valve seat and rotating the valve to ensure a precise seal between the valve face and seat, which is critical for optimal engine compression. Begin by thoroughly cleaning the valve and seat, apply a thin layer of lapping compound, insert the valve into its guide, then use a lapping tool to rotate the valve back and forth with moderate pressure. After achieving an even, matte finish on the contact surface, remove the valve, clean off all abrasive residue, and inspect the valve and seat for proper sealing and smoothness.

Signs Your Engine Valves Need Lapping

Worn or leaking engine valves often cause poor compression, resulting in rough idling and decreased fuel efficiency. Visible carbon buildup and uneven valve seating can signal the need for valve lapping to restore a proper seal. Persistent misfires and reduced engine performance also indicate that valve surfaces require precision lapping to ensure optimal combustion.

Types of Lapping Compounds for Automotive Valves

Automotive valve lapping utilizes various compounds such as coarse, medium, and fine-grit abrasives to ensure optimal sealing and surface finish. Coarse lapping compounds rapidly remove imperfections, while medium compounds refine the valve face, and fine compounds achieve a smooth, precise mating surface essential for engine efficiency. Selecting the appropriate grit type directly impacts valve longevity and combustion performance in internal combustion engines.

Safety Precautions During Valve Lapping

During valve lapping in automotive engines, wearing safety goggles protects eyes from abrasive particles and metal debris. Using gloves prevents skin irritation from grinding compounds and sharp valve edges. Ensuring proper ventilation reduces inhalation of harmful dust generated during the lapping process.

How to Check Valve Sealing After Lapping

To check valve sealing after lapping, place the valve in the cylinder head and apply a thin layer of dye or light oil on the valve seat to visualize contact areas. Next, perform a vacuum or compression test to ensure proper sealing by measuring pressure retention in the combustion chamber. Inspect for any visible gaps or uneven contact patterns on the lapped surfaces that could indicate poor sealing or the need for additional lapping.

Benefits of Proper Valve Lapping in Automobiles

Proper valve lapping in automobiles ensures a precise seal between the valve and valve seat, enhancing engine compression and power output. This process reduces valve leakage and wear, leading to improved fuel efficiency and prolonged engine life. Accurate valve seating also minimizes exhaust emissions by ensuring complete combustion, contributing to better environmental performance.

example of lapping in valve Infographic

samplerz.com

samplerz.com