A pinion in an automotive drivetrain is a small gear that engages with a larger ring gear to transmit torque from the driveshaft to the differential. It is typically found in the final drive assembly of rear-wheel-drive and four-wheel-drive vehicles. The pinion gear's precise teeth design and material composition are critical for efficient power transfer and durability under high rotational speeds. In practical applications, a ring and pinion set is essential for adjusting the gear ratio in a vehicle's axle, impacting acceleration and fuel efficiency. The pinion must withstand significant stress, making high-quality steel alloys and heat treatment processes standard in its manufacturing. Proper maintenance and alignment of the pinion gear help prevent wear and ensure smooth drivetrain operation.

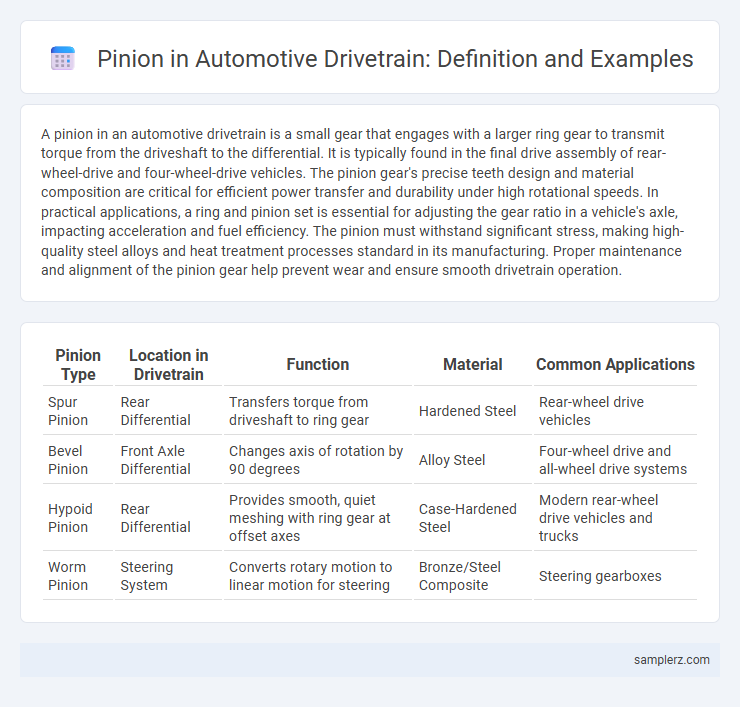

Table of Comparison

| Pinion Type | Location in Drivetrain | Function | Material | Common Applications |

|---|---|---|---|---|

| Spur Pinion | Rear Differential | Transfers torque from driveshaft to ring gear | Hardened Steel | Rear-wheel drive vehicles |

| Bevel Pinion | Front Axle Differential | Changes axis of rotation by 90 degrees | Alloy Steel | Four-wheel drive and all-wheel drive systems |

| Hypoid Pinion | Rear Differential | Provides smooth, quiet meshing with ring gear at offset axes | Case-Hardened Steel | Modern rear-wheel drive vehicles and trucks |

| Worm Pinion | Steering System | Converts rotary motion to linear motion for steering | Bronze/Steel Composite | Steering gearboxes |

Introduction to Pinions in Drivetrain Systems

Pinions in drivetrain systems serve as crucial components that transmit torque and rotational motion between gears, typically meshing with larger gears such as ring gears to facilitate power transfer from the engine to the wheels. In automotive applications, pinions are often found in differential assemblies where they enable smooth torque distribution and vehicle steering responsiveness. High-strength materials like hardened steel are commonly used to manufacture pinions, ensuring durability under high stress and efficient performance in varying driving conditions.

The Role of Pinion Gears in Automotive Drivetrains

Pinion gears in automotive drivetrains transmit torque from the driveshaft to the ring gear, enabling differential function and smooth power transfer to the wheels. These gears are critical for converting rotational motion and adjusting speed and torque within the axle assembly. High-strength materials and precise manufacturing ensure durability and efficiency in handling engine output and vehicle load.

Types of Pinions Used in Vehicle Drivetrains

Types of pinions used in vehicle drivetrains include spiral bevel pinions, hypoid pinions, and straight bevel pinions. Spiral bevel pinions offer smooth operation and high torque capacity, commonly found in rear-wheel-drive differentials. Hypoid pinions allow offset between the driveshaft and axle, improving ground clearance and durability in trucks and SUVs.

Example: Pinion in Rear Axle Differential Assembly

The pinion in a rear axle differential assembly engages with the ring gear to transfer torque from the driveshaft to the wheels, enabling efficient power distribution and smooth vehicle handling. Precision-machined pinion gears ensure durability and optimal meshing with the differential side gears, reducing friction and wear in high-torque conditions. Modern automotive pinion gears commonly utilize hardened steel alloys and advanced surface treatments to withstand the stresses of various driving environments.

Example: Pinion in Manual Transmission Systems

The pinion gear in manual transmission systems engages with the ring gear to transfer rotational motion from the input shaft to the output shaft, enabling gear ratio changes. Typically, the pinion is a small, precisely machined gear that meshes with larger gears to control torque and speed during driving. In manual transmissions, the durability and accurate alignment of the pinion are critical for smooth gear shifts and overall drivetrain efficiency.

Example: Pinion in Rack and Pinion Steering Mechanism

The pinion in a rack and pinion steering mechanism converts rotational motion from the steering wheel into linear motion, driving the rack side to steer the vehicle's wheels. This gear interaction ensures precise control and responsiveness in automotive steering systems. High-quality pinion gears in drivetrain assemblies are essential for durability and smooth operation under variable driving conditions.

Example: Pinion in All-Wheel Drive Transfer Cases

Pinions in all-wheel drive (AWD) transfer cases play a crucial role in distributing torque between the front and rear axles, enhancing vehicle traction and stability. The input pinion engages with the ring gear inside the transfer case, converting rotational motion from the transmission into the rotational force needed to drive multiple axles. High-quality steel pinions with precise gear tooth profiles reduce wear and noise, ensuring efficient power transfer and long drivetrain durability in various driving conditions.

Materials and Design Considerations for Automotive Pinions

Automotive pinions in drivetrains are commonly made from high-strength alloy steels such as 8620 or 9310, chosen for their excellent wear resistance and toughness after carburizing and heat treatment. Design considerations emphasize precise gear tooth geometry with optimized helix angles to minimize noise and maximize load capacity, while surface treatments like nitriding enhance fatigue life and corrosion resistance. The integration of computer-aided engineering (CAE) tools allows for stress analysis and performance optimization, ensuring durability and efficiency under varying torque conditions.

Common Issues and Maintenance of Pinion Components

Pinion gears in automotive drivetrains often face issues such as wear, misalignment, and improper lubrication, leading to noise and reduced efficiency. Regular inspection and timely replacement of worn pinion bearings and seals prevent gear damage and prolong drivetrain life. Ensuring proper gear backlash and using high-quality lubricants are essential maintenance practices to maintain optimal pinion performance.

Future Trends for Pinion Gears in Modern Drivetrains

Future trends for pinion gears in modern drivetrains emphasize the integration of advanced materials such as carbon composites and high-strength alloys to enhance durability and reduce weight. The adoption of precision manufacturing techniques, including additive manufacturing, enables increasingly complex geometries that improve gear meshing efficiency and minimize energy loss. Electrification of vehicles drives the development of optimized pinion designs tailored for electric motor torque characteristics, boosting overall drivetrain performance and reliability.

example of pinion in drivetrain Infographic

samplerz.com

samplerz.com