A cant rail in automotive roof construction is a structural component designed to provide rigidity and support to the vehicle's roof area. This rail typically runs along the edge of the roof, helping to maintain the shape of the roof panel and improve the overall strength of the vehicle's body. It is commonly made from high-strength steel or aluminum to ensure durability and impact resistance. In car manufacturing, the cant rail plays a crucial role in crash safety by reinforcing the roof structure and reducing deformation during rollovers. Data from automotive safety tests show that vehicles with reinforced cant rails experience less roof intrusion, protecting occupants more effectively. Manufacturers often integrate cant rails with other roof components, such as roof pillars and cross members, to optimize the structural integrity and weight distribution of the vehicle.

Table of Comparison

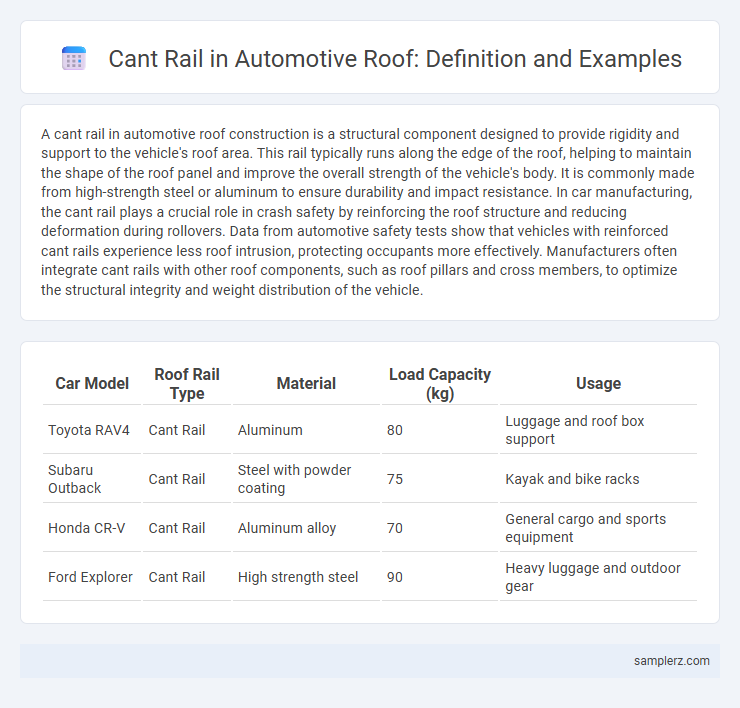

| Car Model | Roof Rail Type | Material | Load Capacity (kg) | Usage |

|---|---|---|---|---|

| Toyota RAV4 | Cant Rail | Aluminum | 80 | Luggage and roof box support |

| Subaru Outback | Cant Rail | Steel with powder coating | 75 | Kayak and bike racks |

| Honda CR-V | Cant Rail | Aluminum alloy | 70 | General cargo and sports equipment |

| Ford Explorer | Cant Rail | High strength steel | 90 | Heavy luggage and outdoor gear |

Introduction to Cant Rail in Automotive Roof Design

Cant rails in automotive roof design serve as structural elements that reinforce the vehicle's roof frame, enhancing overall rigidity and safety during collisions. These rails are typically integrated along the edges of the roof, providing mounting points for roof panels, headliners, and other interior components. Utilizing high-strength steel or aluminum alloys, cant rails improve structural integrity while contributing to weight reduction and improved vehicle performance.

Key Functions of a Cant Rail in Vehicle Roof Structures

A cant rail in vehicle roof structures serves as a critical support beam that enhances the rigidity and strength of the roof assembly, preventing deformation during impacts or rollovers. It also functions as an anchor point for interior components such as headliners and sunroof frames, ensuring structural integrity and noise reduction. Moreover, cant rails contribute to the aerodynamic design by maintaining the roof's shape and supporting weather sealing elements for improved vehicle performance.

Types of Cant Rails Used in Automotive Roofs

Cant rails in automotive roofs primarily consist of aluminum, stainless steel, and composite materials, each chosen for strength, weight, and corrosion resistance. Aluminum cant rails offer a balance of lightweight construction and durability, making them ideal for performance and electric vehicles. Stainless steel rails provide enhanced structural integrity and longevity, often used in luxury cars, while composite cant rails deliver superior flexibility and weight savings for innovative roof designs.

Common Materials for Cant Rails in Car Roof Construction

Common materials for cant rails in car roof construction include high-strength steels, aluminum alloys, and composite materials like carbon fiber-reinforced polymers. High-strength steels provide excellent structural integrity and crash resistance, while aluminum alloys offer lightweight benefits contributing to overall vehicle efficiency. Composite materials enhance strength-to-weight ratios and corrosion resistance, making them increasingly popular in modern automotive design.

Engineering Standards for Cant Rails in Automotive Manufacturing

Cant rails in automotive roof structures must comply with ASTM E330 and ISO 2631 standards to ensure durability and passenger safety under dynamic loads. Engineering specifications require cant rails to achieve a minimum tensile strength of 350 MPa and resist deformation under impact forces exceeding 10 kN. Advanced materials like high-strength steel and aluminum alloys are utilized to meet these stringent performance criteria in automotive manufacturing.

Example: Cant Rail Integration in Modern Sedan Roofs

The cant rail in modern sedan roofs enhances structural integrity by seamlessly integrating with the vehicle's roof framework to improve rigidity and reduce noise. Advanced materials such as high-strength steel or aluminum alloys are used to optimize weight while maintaining safety standards. This integration also supports aerodynamic design, contributing to fuel efficiency and overall vehicle performance.

Example: Cant Rail Application in SUV Roof Assemblies

Cant rail in SUV roof assemblies enhances structural rigidity and improves noise reduction by securely supporting roof panels and glass. This component is often made from high-strength steel or aluminum alloys to balance weight savings with durability. Its integration also facilitates seamless roof gasket placement, boosting weather resistance and overall cabin comfort.

Example: Cant Rail Design in Electric Vehicles (EVs)

Cant rail design in electric vehicles (EVs) enhances structural integrity and maximizes interior space by supporting the roof without bulky pillars. This design integrates lightweight aluminum or high-strength steel materials to improve crash safety while reducing overall vehicle weight. Leading EV manufacturers implement cant rail systems to optimize aerodynamics and battery placement, boosting range efficiency and passenger comfort.

Impact of Cant Rail Design on Vehicle Safety and Crashworthiness

Cant rail design significantly influences vehicle safety and crashworthiness by enhancing the structural integrity of the roof during collisions. Optimized cant rails absorb and distribute impact forces, reducing deformation and protecting occupants from roof intrusion. Advanced materials and geometry in cant rails contribute to improved energy management, directly increasing crash resilience and occupant protection.

Future Trends in Cant Rail Technology for Automotive Roofs

Emerging cant rail technologies for automotive roofs emphasize lightweight materials such as carbon fiber composites and aluminum alloys to enhance vehicle aerodynamics and fuel efficiency. Integration of smart sensors within cant rails supports advanced functionalities like rain detection and solar energy harvesting, contributing to improved user experience and sustainability. Innovations in cant rail design also prioritize modularity and noise reduction, aligning with the growing demand for quieter, more adaptable automotive cabin environments.

example of cant rail in roof Infographic

samplerz.com

samplerz.com