A dry sump lubrication system in automotive applications utilizes an external reservoir to store engine oil separately from the crankcase. This setup prevents oil starvation during high-performance driving or off-road conditions by maintaining a consistent oil supply and pressure. The system typically includes multiple scavenge pumps that return oil from the engine sump to the external tank, enhancing engine reliability and longevity. High-end sports cars and race vehicles often employ dry sump systems to improve engine cooling and reduce parasitic drag caused by windage losses. The external oil reservoir allows for increased oil capacity and improved temperature control, which are critical under extreme operating conditions. Manufacturers such as Porsche and Ferrari implement dry sump lubrication to achieve optimal engine performance and durability.

Table of Comparison

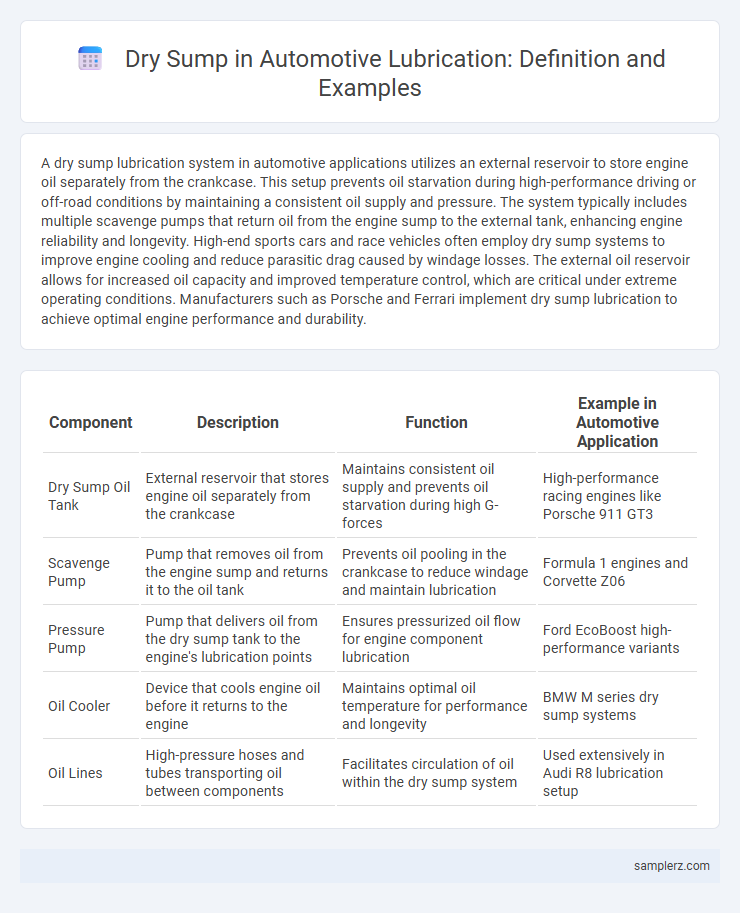

| Component | Description | Function | Example in Automotive Application |

|---|---|---|---|

| Dry Sump Oil Tank | External reservoir that stores engine oil separately from the crankcase | Maintains consistent oil supply and prevents oil starvation during high G-forces | High-performance racing engines like Porsche 911 GT3 |

| Scavenge Pump | Pump that removes oil from the engine sump and returns it to the oil tank | Prevents oil pooling in the crankcase to reduce windage and maintain lubrication | Formula 1 engines and Corvette Z06 |

| Pressure Pump | Pump that delivers oil from the dry sump tank to the engine's lubrication points | Ensures pressurized oil flow for engine component lubrication | Ford EcoBoost high-performance variants |

| Oil Cooler | Device that cools engine oil before it returns to the engine | Maintains optimal oil temperature for performance and longevity | BMW M series dry sump systems |

| Oil Lines | High-pressure hoses and tubes transporting oil between components | Facilitates circulation of oil within the dry sump system | Used extensively in Audi R8 lubrication setup |

Introduction to Dry Sump Lubrication in Automotive Engines

Dry sump lubrication systems in automotive engines use an external reservoir to store oil, ensuring consistent oil pressure and improved cooling during high-performance conditions. This design reduces oil aeration and prevents oil starvation in extreme cornering or racing scenarios. Commonly found in race cars and high-performance sports vehicles, dry sump systems enhance engine reliability and longevity by maintaining optimal lubrication under demanding circumstances.

Key Components of Dry Sump Systems

Dry sump lubrication systems utilize key components such as an external oil reservoir, a scavenge pump, and a pressure pump to efficiently manage engine oil flow and temperature. The scavenge pump removes oil from the engine sump, preventing oil starvation during high-performance driving conditions, while the pressure pump circulates oil back to the engine components for optimal lubrication. An oil cooler and filtration unit are often integrated to maintain oil quality and enhance system reliability in racing and high-performance automotive engines.

Advantages of Dry Sump Lubrication Over Wet Sump

Dry sump lubrication systems prevent oil starvation by maintaining consistent oil pressure during high-performance driving and sharp cornering, which is crucial for automotive engines subjected to extreme conditions. These systems reduce engine oil aeration and overheating by storing oil in an external reservoir, enhancing overall lubrication efficiency and prolonging engine life. The compact design of dry sump systems also allows for lower engine placement, improving vehicle handling and center of gravity.

Notable Automotive Applications Using Dry Sump

Notable automotive applications using dry sump lubrication include high-performance racing engines such as those in Formula 1 cars, Porsche 911 GT3 RS, and Chevrolet Corvette Z06. These systems enhance engine reliability by preventing oil starvation during high-speed cornering and aggressive acceleration. The dry sump design also contributes to lower engine placement, improving vehicle center of gravity and overall handling performance.

Example: Dry Sump in High-Performance Sports Cars

High-performance sports cars like the Porsche 911 GT3 utilize dry sump lubrication systems to maintain consistent oil pressure during extreme cornering and acceleration. This system stores oil in an external reservoir, preventing oil starvation and ensuring optimal engine performance under high G-forces. The dry sump design also reduces engine height, allowing for improved vehicle handling and aerodynamics.

Example: Dry Sump in Racing Cars and Motorsports

Dry sump lubrication systems in racing cars enhance engine reliability by preventing oil starvation during high-speed cornering and extreme G-forces. These systems use external reservoirs and multiple scavenging pumps to maintain consistent oil pressure and temperature, ensuring optimal engine performance under rigorous motorsport conditions. Formula 1 and endurance racing vehicles frequently adopt dry sump systems to maximize power output and engine durability.

Example: Dry Sump in Off-Road and Rally Vehicles

Dry sump lubrication systems are commonly used in off-road and rally vehicles to ensure consistent oil pressure and lubrication even during extreme vehicle attitudes and high G-forces. By employing external oil reservoirs, dry sump systems prevent oil starvation and improve engine reliability under demanding conditions typical of motorsports. This setup enhances engine cooling and reduces windage losses, contributing to better overall performance in rugged terrain and aggressive driving scenarios.

Maintenance Considerations for Dry Sump Systems

Dry sump lubrication systems require regular inspection of external oil reservoirs and scavenging pumps to prevent oil starvation and ensure consistent oil pressure. Scheduled maintenance must include checking hoses and fittings for leaks or wear, as failures can lead to catastrophic engine damage. Monitoring oil quality and circulation is essential to maintain optimal engine performance and longevity in high-performance automotive applications.

Challenges and Limitations of Dry Sump Lubrication

Dry sump lubrication systems face challenges such as increased complexity and cost due to additional components like external oil reservoirs and scavenging pumps. Limited space in high-performance automotive engines can complicate installation and maintenance, potentially impacting vehicle design flexibility. Furthermore, improper system tuning may lead to oil starvation or aeration, reducing engine reliability and longevity.

Future Trends in Automotive Dry Sump Technology

Future trends in automotive dry sump lubrication include the integration of advanced sensors and IoT connectivity to monitor oil pressure and temperature in real time, enhancing engine protection and performance. Lightweight materials such as carbon fiber and aluminum alloys are increasingly employed to reduce system weight and improve heat dissipation. Electrification of drivetrain components is driving innovations in dry sump designs tailored for hybrid and electric vehicles, optimizing lubrication under variable operating conditions.

example of dry sump in lubrication Infographic

samplerz.com

samplerz.com