A spool in a turbocharger refers to the rotating assembly that includes the turbine wheel, compressor wheel, and the shaft connecting them. This component plays a critical role in converting exhaust gas energy into compressed air to increase engine efficiency and power output. The speed at which the spool rotates directly influences the turbocharger's ability to boost engine performance by forcing more air into the combustion chamber. Turbocharger spool speed can reach up to 150,000 RPM, depending on the turbocharger's size and design. The inertia of the spool affects turbo lag, which is the delay between throttle input and boost pressure build-up. Optimized spool design, involving lightweight materials and precise aerodynamics, improves response time and overall engine driveability in automotive applications.

Table of Comparison

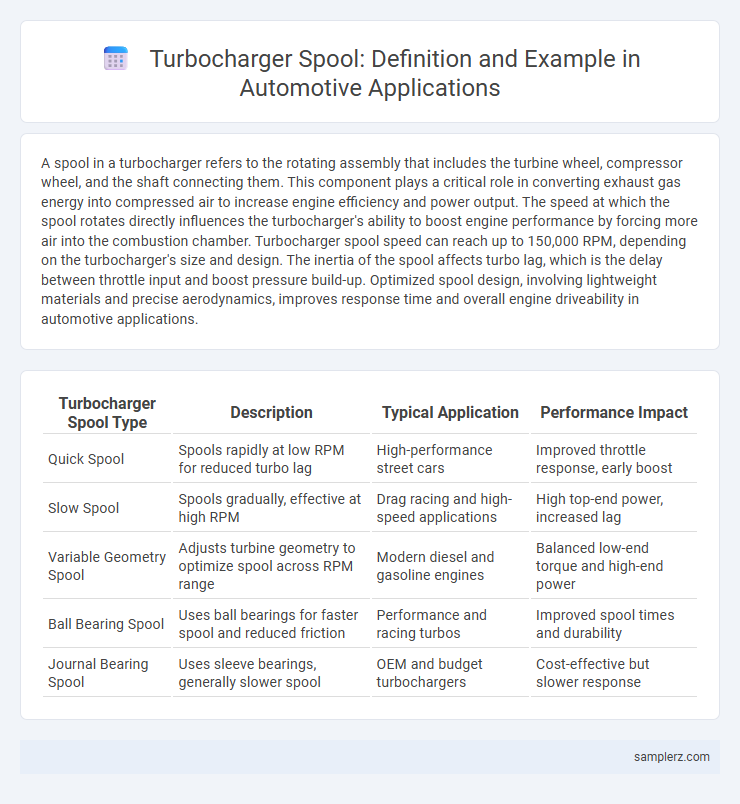

| Turbocharger Spool Type | Description | Typical Application | Performance Impact |

|---|---|---|---|

| Quick Spool | Spools rapidly at low RPM for reduced turbo lag | High-performance street cars | Improved throttle response, early boost |

| Slow Spool | Spools gradually, effective at high RPM | Drag racing and high-speed applications | High top-end power, increased lag |

| Variable Geometry Spool | Adjusts turbine geometry to optimize spool across RPM range | Modern diesel and gasoline engines | Balanced low-end torque and high-end power |

| Ball Bearing Spool | Uses ball bearings for faster spool and reduced friction | Performance and racing turbos | Improved spool times and durability |

| Journal Bearing Spool | Uses sleeve bearings, generally slower spool | OEM and budget turbochargers | Cost-effective but slower response |

Understanding Spool in Turbochargers

Spool in turbochargers refers to the process where the turbine and compressor wheels rapidly accelerate to their operating speed, enabling efficient air compression and increased engine power. The spool time directly influences turbo lag, with smaller, lightweight spools achieving faster response times. Understanding spool characteristics is crucial for optimizing boost pressure and enhancing overall turbocharger performance in automotive applications.

Key Factors Affecting Turbo Spool

Turbo spool in automotive turbochargers is primarily affected by turbine housing size, compressor wheel design, and exhaust gas energy. Smaller turbine housings and lightweight compressor wheels reduce rotational inertia, enabling quicker spool-up and improved throttle response. High exhaust gas velocity and temperature also contribute to faster spool times by increasing turbine energy transfer efficiency.

Example of Fast Turbo Spool Dynamics

Fast turbo spool dynamics are exemplified by the use of lightweight turbine wheels and advanced ball bearing systems, which reduce rotational inertia and minimize lag. Modern turbochargers achieve spool times under 200 milliseconds by optimizing aerodynamics and employing variable geometry technology to adjust exhaust flow rapidly. These enhancements enable quicker boost delivery, improving engine responsiveness and overall performance in automotive applications.

Variable Geometry Turbocharger Spool Characteristics

The spool in a Variable Geometry Turbocharger (VGT) adjusts turbine geometry to optimize boost pressure across a wide RPM range, minimizing turbo lag and improving engine efficiency. VGT spool characteristics include rapid response times and variable vane angles that adapt to engine load and speed, enhancing performance and fuel economy. This dynamic adjustment allows the turbocharger to maintain optimal airflow and pressure, contributing to reduced emissions and increased torque delivery.

Twin-Scroll Turbocharger Spool Behavior

The twin-scroll turbocharger spool behavior enhances engine performance by separating exhaust pulses into two channels, reducing turbo lag and improving turbine response time. Each scroll optimizes exhaust gas flow from specific cylinder pairs, increasing energy transfer and enabling quicker spool-up compared to single-scroll designs. This results in higher boost pressure at lower RPMs, improving throttle response and overall engine efficiency.

Single vs Twin Turbo Spool Examples

Single turbo spools offer straightforward design with one turbine wheel compressing exhaust gases, providing simpler maintenance and cost efficiency but often resulting in turbo lag at lower RPMs. Twin turbo spool configurations split exhaust flow between two smaller turbines, delivering faster spool-up times and improved low-end torque by reducing rotational inertia. In performance automotive applications, single turbos excel in high RPM power delivery, while twin turbos enhance throttle response and drivability across a broader range of engine speeds.

Impacts of Spool on Engine Performance

The spool in a turbocharger directly influences engine responsiveness and boost pressure buildup, resulting in improved power delivery and fuel efficiency. Rapid spool-up reduces turbo lag, enhancing throttle reaction and acceleration, particularly at lower RPMs. Efficient spool dynamics also optimize exhaust gas energy utilization, contributing to increased overall engine performance and reduced emissions.

Spool Time Comparisons: Small vs Large Turbos

Small turbochargers exhibit significantly faster spool times due to lower rotational inertia, enabling quicker boost response and improved low-end torque delivery. Larger turbos, while slower to spool, provide higher peak power and sustained boost at elevated engine speeds, benefiting high-performance and heavy-duty applications. Optimizing spool time requires balancing turbo size with engine characteristics to achieve desired performance and efficiency targets.

Techniques to Improve Turbo Spool

Improving turbo spool involves optimizing the turbine wheel design, such as using lightweight materials like titanium aluminide to reduce inertia and enhance responsiveness. Advanced techniques include variable geometry turbochargers (VGT) that adjust the turbine's vane angles to maintain optimal exhaust gas velocity at different engine speeds. Balancing compressor and turbine efficiency while minimizing turbo lag through twin-scroll designs or sequential turbocharging also significantly improves spool characteristics.

Real-World Applications: Spool in Motorsport Turbochargers

In motorsport turbochargers, spool time critically impacts engine responsiveness and power delivery during races. High-performance turbine spools, engineered with lightweight materials like titanium and advanced aerodynamics, reduce lag and enable rapid boost pressure buildup. These innovations enhance acceleration and overall vehicle dynamics, providing competitive advantages in professional automotive racing.

example of spool in turbocharger Infographic

samplerz.com

samplerz.com