Spalling in automotive bearings occurs when small flakes of material break away from the bearing surface, leading to rough operation and eventual failure. This defect typically results from fatigue caused by excessive load, contamination, or inadequate lubrication in components such as wheel bearings or transmission bearings. Measuring wear debris in lubricants can help detect early signs of spalling and prevent severe mechanical damage. Spalled bearings compromise vehicle performance by increasing friction and heat generation, which accelerates wear on associated parts like shafts and housings. Data from vibration analysis and temperature sensors often highlight abnormalities that correlate with spalling incidents. Monitoring these parameters helps manufacturers improve bearing materials and enhance automotive reliability and safety.

Table of Comparison

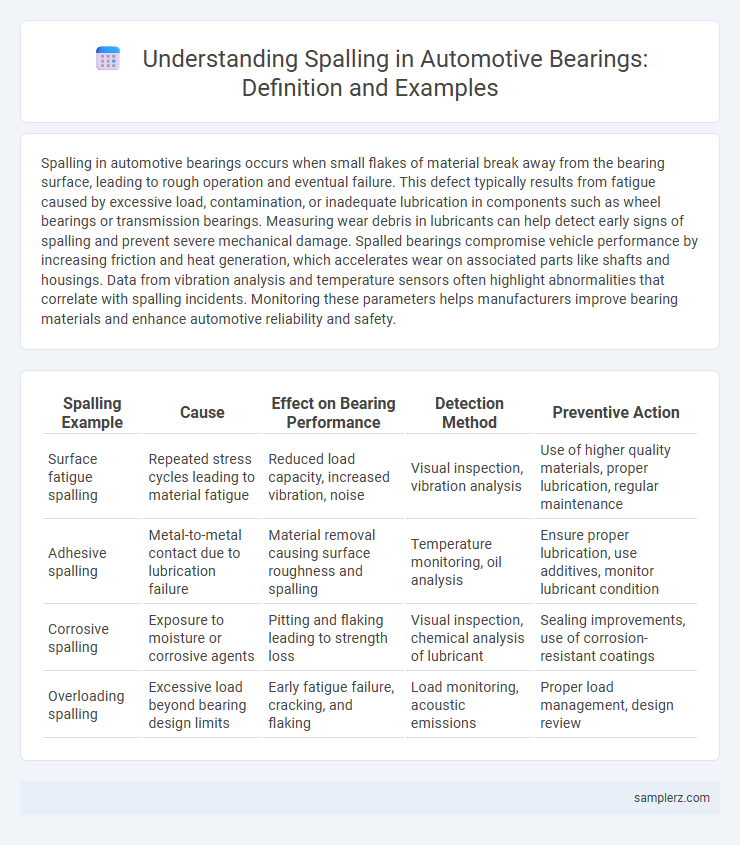

| Spalling Example | Cause | Effect on Bearing Performance | Detection Method | Preventive Action |

|---|---|---|---|---|

| Surface fatigue spalling | Repeated stress cycles leading to material fatigue | Reduced load capacity, increased vibration, noise | Visual inspection, vibration analysis | Use of higher quality materials, proper lubrication, regular maintenance |

| Adhesive spalling | Metal-to-metal contact due to lubrication failure | Material removal causing surface roughness and spalling | Temperature monitoring, oil analysis | Ensure proper lubrication, use additives, monitor lubricant condition |

| Corrosive spalling | Exposure to moisture or corrosive agents | Pitting and flaking leading to strength loss | Visual inspection, chemical analysis of lubricant | Sealing improvements, use of corrosion-resistant coatings |

| Overloading spalling | Excessive load beyond bearing design limits | Early fatigue failure, cracking, and flaking | Load monitoring, acoustic emissions | Proper load management, design review |

Understanding Spalling in Automotive Bearings

Spalling in automotive bearings occurs when surface fatigue causes small particles to break away, leading to rough, pitted bearing surfaces that impair performance. This defect often arises from excessive loads, inadequate lubrication, or contamination, increasing friction and accelerating wear within engines and wheel assemblies. Detecting spalling early through vibration analysis or visual inspection is critical to prevent catastrophic bearing failure and costly vehicle downtime.

Common Signs of Spalling in Bearings

Common signs of spalling in automotive bearings include visible flaking or pitting on the bearing surface, increased operational noise such as grinding or knocking, and elevated vibration levels detected during engine or wheel rotation. These symptoms indicate metal fatigue and surface degradation, often caused by excessive load, lubrication failure, or contamination. Early detection of spalling through these indicators helps prevent bearing failure and maintains vehicle performance.

Causes of Spalling in Automotive Applications

Spalling in automotive bearings primarily results from fatigue caused by repeated stress cycles exceeding the material's endurance limit. Contaminants such as dirt, debris, and inadequate lubrication accelerate surface degradation, leading to micro-cracks and eventual material flaking. Thermal effects from excessive heat generation further weaken bearing surfaces, increasing the likelihood of spalling and reducing bearing lifespan.

Visual Examples of Bearing Spalling

Bearing spalling manifests as distinct surface defects characterized by flakes or pits breaking away from the metal raceway, often visible under close inspection. Visual examples include small craters, rough patches, and irregular metallic debris, indicating localized fatigue and material separation. These signs typically appear on inner or outer rings and rolling elements, leading to increased vibration and noise in automotive wheel or engine bearings.

Case Study: Spalling Failure in Car Wheel Bearings

A case study of spalling failure in car wheel bearings highlights the critical role of material fatigue caused by excessive load and inadequate lubrication. Microscopic inspection revealed surface cracks and flaking on bearing raceways, leading to progressive degradation and eventual bearing failure. This failure mode significantly compromised vehicle safety and performance, emphasizing the importance of regular maintenance and high-quality bearing materials.

Effects of Spalling on Vehicle Performance

Spalling in automotive bearings causes surface material to break away, leading to increased friction and vibration within the wheel assembly. This deterioration results in decreased fuel efficiency, compromised handling, and accelerated wear of associated drivetrain components. Persistent spalling can cause bearing failure, posing safety risks and costly repairs for the vehicle.

Diagnostic Methods for Detecting Bearing Spalling

Vibration analysis is a crucial diagnostic method for detecting bearing spalling, as it identifies characteristic high-frequency oscillations caused by surface defects. Acoustic emission monitoring complements this by capturing transient stress waves generated from crack initiation and propagation on bearing surfaces. Infrared thermography detects localized temperature increases indicative of friction and spalling damage, enabling early intervention in automotive bearing maintenance.

Preventive Measures Against Bearing Spalling

Preventive measures against bearing spalling in automotive applications include maintaining proper lubrication with high-quality, contamination-free oils and greases to minimize surface fatigue. Regular inspection and timely replacement of bearings exposed to excessive load or misalignment reduce the risk of surface cracking and flaking. Utilizing advanced materials with enhanced fatigue resistance and adopting precise installation techniques further extend bearing lifespan and prevent spalling defects.

Repair Solutions for Spalled Bearings

Spalling in bearings, caused by surface fatigue or contamination, leads to pitting and flaking that compromise vehicle performance. Effective repair solutions for spalled bearings include precision grinding and polishing to restore smooth surfaces, combined with the application of specialized coatings that enhance durability and reduce friction. Implementing these targeted repairs can extend bearing lifespan and improve reliability in automotive systems.

Role of Lubrication in Preventing Bearing Spalling

Bearing spalling in automotive applications occurs due to surface fatigue caused by micro-cracks generated under high stress and inadequate lubrication. Proper lubrication forms a protective film that reduces friction, dissipates heat, and prevents metal-to-metal contact, significantly extending bearing life. Advanced synthetic lubricants with anti-wear additives enhance load-carrying capacity, minimize wear particles, and maintain optimal viscosity under extreme operating conditions.

example of spalling in bearing Infographic

samplerz.com

samplerz.com