In automotive design, a valance on a bumper refers to a molded component that enhances both the aesthetic and aerodynamic performance of the vehicle. Typically made from plastic or composite materials, valances fill the gap between the bumper and the vehicle's undercarriage. This part serves to direct airflow efficiently, reducing drag and improving fuel efficiency while providing a sleek, finished look to the front or rear end of the car. Valances often integrate with features such as fog light housings, air intakes, or protective skid plates, contributing to the vehicle's overall functionality. Data from crash tests show that valances can also offer minor impact absorption, protecting more critical mechanical components behind the bumper. Manufacturers optimize these elements using CAD software and wind tunnel testing to balance design appeal with performance metrics.

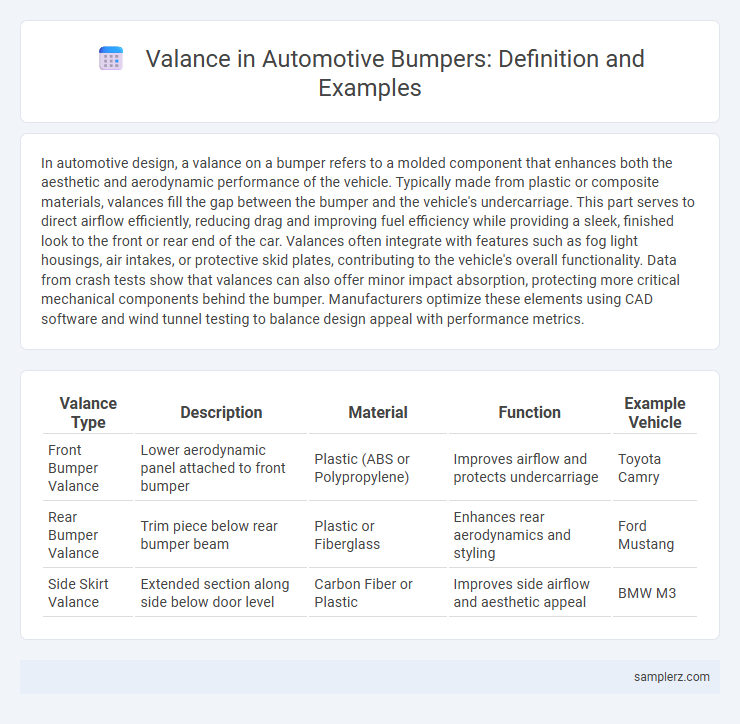

Table of Comparison

| Valance Type | Description | Material | Function | Example Vehicle |

|---|---|---|---|---|

| Front Bumper Valance | Lower aerodynamic panel attached to front bumper | Plastic (ABS or Polypropylene) | Improves airflow and protects undercarriage | Toyota Camry |

| Rear Bumper Valance | Trim piece below rear bumper beam | Plastic or Fiberglass | Enhances rear aerodynamics and styling | Ford Mustang |

| Side Skirt Valance | Extended section along side below door level | Carbon Fiber or Plastic | Improves side airflow and aesthetic appeal | BMW M3 |

Introduction to Bumper Valance: Definition and Function

A bumper valance is a lower panel attached beneath the main bumper, designed to enhance aerodynamic efficiency and protect the vehicle's undercarriage from debris and minor impacts. This component often features integrated air vents or channels to improve airflow, reducing drag and contributing to fuel efficiency. In automotive design, bumper valances also serve aesthetic purposes, providing a seamless and sporty appearance to the front or rear fascia of the vehicle.

Types of Bumper Valance Panels in Modern Vehicles

Bumper valance panels, integral to modern automotive design, vary across types such as molded plastic, carbon fiber, and metal-reinforced trims, each offering distinct advantages in weight, durability, and aesthetic appeal. Molded plastic valances excel in impact absorption and cost efficiency, while carbon fiber panels provide superior strength and lightweight performance favored in sports vehicles. Metal-reinforced valances combine robustness with enhanced protection, commonly used in heavy-duty trucks and SUVs to withstand harsh driving conditions.

Front Bumper Valance Examples in Popular Cars

Front bumper valances on popular cars such as the Toyota Camry and Honda Civic improve aerodynamics and enhance visual appeal while protecting undercarriage components. Models like the Ford Mustang feature aggressive front bumper valances designed to channel airflow efficiently, reducing drag and increasing performance. High-end vehicles, including the BMW 3 Series, integrate stylish front valances that combine functionality with sleek, sporty aesthetics.

Rear Bumper Valance Applications and Styles

Rear bumper valance applications enhance both the aerodynamics and aesthetics of vehicles, often featuring integrated diffuser designs and cutouts for exhaust outlets. Common styles include smooth, sculpted surfaces and aggressive, vented configurations that improve airflow and reduce drag. Lightweight materials such as ABS plastic or carbon fiber are preferred for durability and weight reduction in aftermarket and OEM installations.

OEM vs Aftermarket Bumper Valance Options

OEM bumper valances are designed to match the exact specifications, materials, and finishes of the original vehicle, ensuring perfect fitment and durability. Aftermarket bumper valances offer a wide range of styles and often use varied materials such as ABS plastic or fiberglass, providing cost-effective customization options but sometimes compromising on long-term resilience. Choosing between OEM and aftermarket valances depends on balancing vehicle aesthetic consistency and budget flexibility while considering installation ease and warranty coverage.

Material Choices for Bumper Valance Panels

Automotive bumper valance panels commonly utilize thermoplastic materials such as polypropylene (PP) and thermoplastic olefins (TPO) due to their excellent impact resistance and lightweight properties. Advanced composites incorporating glass fiber or carbon fiber enhance stiffness and durability while maintaining corrosion resistance. Material selections prioritize a balance between energy absorption, manufacturability, and cost-effectiveness for improved vehicle safety and design flexibility.

Aerodynamic Benefits of a Well-Designed Valance

A well-designed valance on a bumper reduces aerodynamic drag by directing airflow smoothly around the vehicle's undercarriage, improving fuel efficiency. It minimizes air turbulence and lift at higher speeds, enhancing vehicle stability and handling. Optimized valance shapes contribute to lower wind resistance, playing a crucial role in performance and emissions reduction for modern automobiles.

Aesthetic Impact: Valance Styles for Sporty Look

A valance on a bumper enhances a vehicle's sporty aesthetic by adding aggressive, aerodynamic lines that emphasize performance and speed. Popular valance styles include diffuser-inspired designs, sharp contours, and integrated air vents that create a dynamic, race-ready appearance. These elements not only improve visual appeal but can also contribute to improved airflow and downforce, reinforcing the sporty character.

Installation Process for Bumper Valance Examples

The installation process for bumper valances typically involves aligning the valance with existing mounting points on the bumper, securing it using factory or aftermarket fasteners such as screws, clips, or bolts, and ensuring proper fitment to avoid gaps or misalignment. For example, in many Honda Civic models, the valance can be installed by removing the lower bumper cover, positioning the valance piece accurately, and reattaching all components while tightening all fasteners to manufacturer torque specifications. Proper installation enhances aerodynamic performance and protects the vehicle's undercarriage from debris.

Maintenance and Replacement Tips for Valance Panels

Maintaining valance panels on bumpers requires regular inspection for cracks, dents, and corrosion to prevent further damage. Replacement involves choosing OEM or high-quality aftermarket parts that ensure proper fit and durability, followed by professional installation to maintain vehicle safety and appearance. Cleaning with mild detergents and avoiding abrasive tools prolongs the lifespan of valance panels.

example of valance in bumper Infographic

samplerz.com

samplerz.com