A hanger in an automotive exhaust system is a crucial component designed to support and secure the exhaust pipe and muffler underneath the vehicle. These hangers are typically made of rubber or metal and help absorb vibrations, preventing the exhaust components from excessive movement or damage. Common types include rubber hanger mounts, metal brackets, and insulated hooks, each serving to maintain proper alignment and reduce noise. Exhaust hangers are strategically placed along the exhaust system, connecting to mounting points on the vehicle's chassis. Data from OEM specifications shows that improper hanger installation can lead to exhaust leaks, increased emissions, and reduced fuel efficiency. Automotive manufacturers prioritize the durability and flexibility of these hangers to ensure long-lasting performance and compliance with environmental standards.

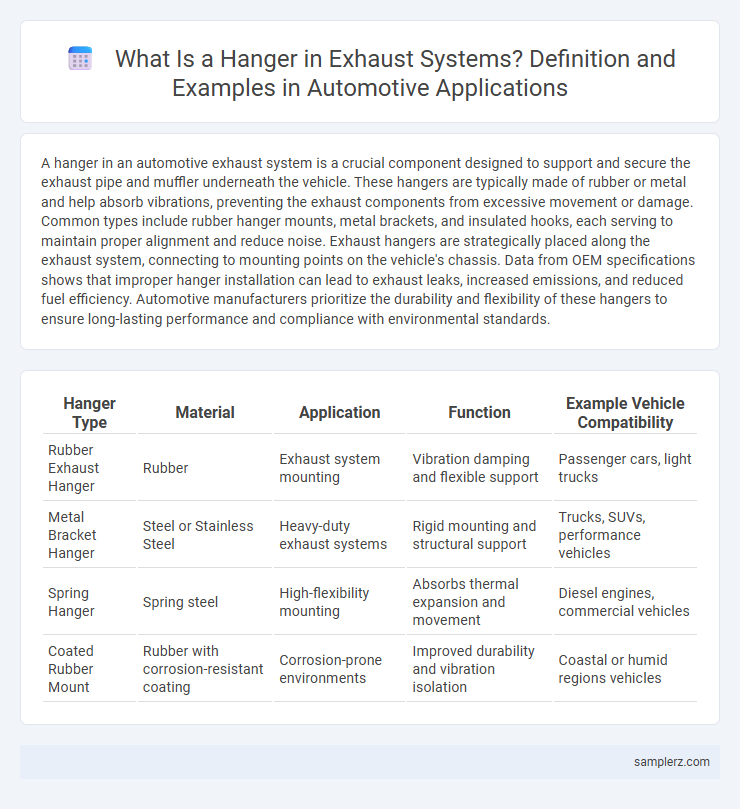

Table of Comparison

| Hanger Type | Material | Application | Function | Example Vehicle Compatibility |

|---|---|---|---|---|

| Rubber Exhaust Hanger | Rubber | Exhaust system mounting | Vibration damping and flexible support | Passenger cars, light trucks |

| Metal Bracket Hanger | Steel or Stainless Steel | Heavy-duty exhaust systems | Rigid mounting and structural support | Trucks, SUVs, performance vehicles |

| Spring Hanger | Spring steel | High-flexibility mounting | Absorbs thermal expansion and movement | Diesel engines, commercial vehicles |

| Coated Rubber Mount | Rubber with corrosion-resistant coating | Corrosion-prone environments | Improved durability and vibration isolation | Coastal or humid regions vehicles |

Understanding Exhaust Hanger Systems in Vehicles

Exhaust hanger systems in vehicles secure the exhaust pipe and muffler, minimizing vibrations and noise while preventing damage from road shocks and engine movement. These hangers are typically made from durable rubber or metal, designed to withstand high temperatures and harsh conditions. Proper maintenance of exhaust hangers ensures optimal exhaust alignment, reducing the risk of leaks and improving overall vehicle performance.

Common Types of Exhaust Hangers Used in Automobiles

Common types of exhaust hangers used in automobiles include rubber isolators, metal clamps, and welded brackets, each designed to secure the exhaust system while absorbing vibrations and reducing noise. Rubber isolators are preferred for their flexibility and durability, providing effective cushioning between the exhaust pipe and vehicle chassis. Metal clamps offer strong support for heavier exhaust components, while welded brackets ensure permanent attachment in custom exhaust setups.

Role of Exhaust Hangers in Vibration Reduction

Exhaust hangers play a critical role in reducing vibrations by securely suspending the exhaust system while allowing controlled movement to absorb engine and road-induced vibrations. These components, typically made from durable rubber or composite materials, isolate the exhaust system from the vehicle's chassis, preventing metal-to-metal contact that causes noise and wear. Properly designed exhaust hangers enhance ride comfort and prolong the lifespan of exhaust components by minimizing stress and vibration-induced damage.

Materials Commonly Used for Exhaust Hangers

Exhaust hangers are typically made from durable materials such as rubber, stainless steel, and aluminized steel to withstand high temperatures and harsh environmental conditions. Rubber provides flexibility and vibration damping, while stainless steel and aluminized steel offer corrosion resistance and structural strength. These materials ensure the hanger securely supports the exhaust system and maintains its alignment under dynamic driving conditions.

Rubber vs. Metal Exhaust Hangers: Pros and Cons

Rubber exhaust hangers provide superior vibration isolation and noise reduction by absorbing engine vibrations, enhancing ride comfort and preventing exhaust system damage. Metal exhaust hangers offer greater durability and resistance to heat and corrosion, ensuring long-term stability but may transmit more noise and vibration to the vehicle cabin. Selecting between rubber and metal hangers depends on balancing comfort preferences with durability requirements in automotive exhaust system design.

Signs of a Worn or Broken Exhaust Hanger

A worn or broken exhaust hanger often causes excessive exhaust system movement, resulting in rattling noises or vibrations during vehicle operation. Visible signs include sagging or misaligned exhaust pipes, rubber components that appear cracked, brittle, or missing entirely. Ignoring these symptoms may lead to further damage of the exhaust system, increased emissions, and potential safety hazards.

How to Identify the Right Exhaust Hanger for Your Car

To identify the right exhaust hanger for your car, verify the hanger's compatibility by matching the vehicle's make, model, and exhaust system configuration, as improper fit can cause vibrations and exhaust misalignment. Inspect the material composition, typically rubber for flexibility and metal reinforcement for durability, ensuring it withstands heat and road conditions. Consult OEM specifications or manufacturer guidelines to select a hanger that maintains proper exhaust positioning and reduces noise and wear.

Installation Tips for Automotive Exhaust Hangers

Automotive exhaust hangers require precise positioning to effectively absorb vibrations and secure the exhaust system. Ensuring hangers are made from durable materials such as high-grade rubber or metal composites enhances longevity and performance under high-temperature conditions. Proper alignment during installation prevents premature wear and reduces exhaust noise, maintaining system integrity and vehicle safety.

Aftermarket Upgrades for Exhaust Hanger Systems

Aftermarket upgrades for exhaust hanger systems enhance vibration isolation and durability, using materials like high-strength rubber or polyurethane to reduce noise and improve longevity. Customizable hanger mounts ensure precise fitment for performance exhausts, preventing sagging and misalignment. Advanced designs also incorporate corrosion-resistant coatings to withstand harsh environmental conditions, extending the exhaust system's lifespan.

Maintenance Tips to Prolong Exhaust Hanger Life

Regularly inspect exhaust hangers for signs of wear, cracks, or corrosion to prevent premature failure. Apply high-temperature resistant silicone lubricant to rubber hangers to maintain flexibility and reduce friction. Ensure hanger brackets are securely fastened and avoid excessive engine vibrations by checking mounting points and exhaust system alignment.

example of hanger in exhaust Infographic

samplerz.com

samplerz.com