A tumble in the intake manifold refers to the rotational motion of the air-fuel mixture as it enters the combustion chamber, enhancing fuel atomization and combustion efficiency. This phenomenon is engineered through specific manifold designs such as intake runners with angled ports or tumble flaps that create a vertical swirling effect. Tumble motion improves the mixing process, leading to better flame propagation, reduced emissions, and increased engine performance. Manufacturers integrate tumble mechanisms in gasoline direct injection (GDI) engines to optimize combustion under various operating conditions. Sensors and actuators in the intake system control the tumble flow dynamically, adapting to engine speed and load for optimal air-fuel mixture homogeneity. Effective tumble management contributes to meeting stringent emission standards while maintaining power output and fuel economy in modern automotive engines.

Table of Comparison

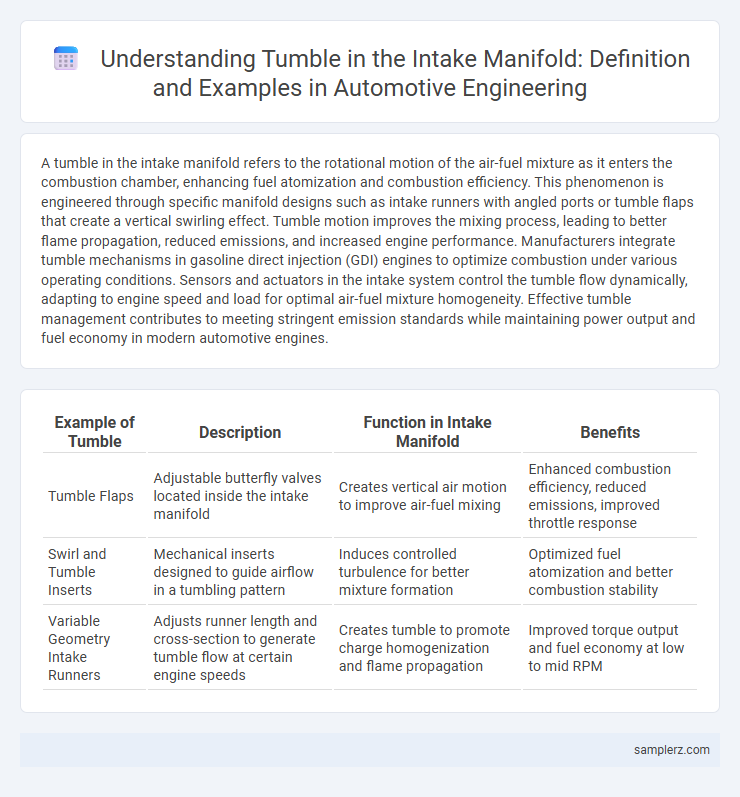

| Example of Tumble | Description | Function in Intake Manifold | Benefits |

|---|---|---|---|

| Tumble Flaps | Adjustable butterfly valves located inside the intake manifold | Creates vertical air motion to improve air-fuel mixing | Enhanced combustion efficiency, reduced emissions, improved throttle response |

| Swirl and Tumble Inserts | Mechanical inserts designed to guide airflow in a tumbling pattern | Induces controlled turbulence for better mixture formation | Optimized fuel atomization and better combustion stability |

| Variable Geometry Intake Runners | Adjusts runner length and cross-section to generate tumble flow at certain engine speeds | Creates tumble to promote charge homogenization and flame propagation | Improved torque output and fuel economy at low to mid RPM |

Understanding Tumble Flow in Intake Manifolds

Tumble flow in intake manifolds refers to the rotational motion of the air-fuel mixture as it enters the combustion chamber, enhancing turbulence for improved mixing and combustion efficiency. This aerodynamic characteristic promotes better atomization of fuel, leading to more complete combustion and reduced emissions. Optimizing tumble flow is critical in modern engines to achieve higher power output and fuel economy while meeting stringent environmental regulations.

Importance of Tumble Motion for Combustion Efficiency

Tumble motion in the intake manifold creates a vertical swirling airflow that enhances fuel-air mixing and promotes faster, more complete combustion within the cylinder. This optimized turbulence ensures improved flame propagation and reduces emissions by minimizing unburned hydrocarbons. Efficient tumble motion directly contributes to better fuel economy and increased engine performance in modern automotive engines.

How Intake Manifold Design Creates Tumble

The intake manifold design creates tumble by directing airflow through specially shaped runners that induce a rotational motion around the cylinder's axis, enhancing air-fuel mixture turbulence. This tumble motion improves combustion efficiency by promoting better mixing and faster flame propagation. Utilizing curved or helical intake paths and optimized runner geometry increases tumble intensity, leading to enhanced engine performance and reduced emissions.

Example 1: Tumble Generation in Inline-Four Engines

Tumble generation in inline-four engines occurs when the intake manifold design directs airflow to create a vertical swirling motion, enhancing the air-fuel mixture's turbulence during the intake stroke. This increased turbulence improves combustion efficiency and reduces emissions by promoting better fuel atomization and faster flame propagation. Optimized tumble motion directly contributes to higher engine performance and lower fuel consumption in modern automotive applications.

Example 2: Tumble Flow in Direct Injection Gasoline Engines

Tumble flow in direct injection gasoline engines enhances air-fuel mixing by creating a strong rotational motion perpendicular to the intake valve axis, improving combustion efficiency and reducing emissions. This tumble motion is generated by specific intake port designs and intake valve timings that promote vertical swirling of the air charge. Optimizing tumble flow contributes to better flame propagation and fuel atomization, leading to higher power output and lower fuel consumption.

Effects of Tumble on Air-Fuel Mixing

Tumble flow in the intake manifold enhances air-fuel mixing by creating strong rotational motion perpendicular to the cylinder axis, promoting turbulence and homogeneous mixture formation. This improved mixing results in more efficient combustion, leading to increased power output and reduced emissions. Optimizing tumble intensity can significantly impact engine performance and fuel efficiency by ensuring thorough vaporization and distribution of the fuel-air mixture.

Case Study: Tumble in Turbocharged vs. Naturally Aspirated Engines

Tumble flow in the intake manifold significantly influences combustion efficiency and emissions in automotive engines. In turbocharged engines, enhanced tumble motion improves air-fuel mixing under higher intake pressures, leading to better combustion stability and increased power output compared to naturally aspirated engines. Case studies demonstrate that optimizing tumble in turbocharged manifolds results in reduced NOx emissions and improved fuel economy through more complete combustion cycles.

Measurement Techniques for Tumble in Intake Manifolds

Measurement techniques for tumble in intake manifolds often involve Particle Image Velocimetry (PIV), Laser Doppler Anemometry (LDA), and Hot-Wire Anemometry (HWA) to capture flow velocity and turbulence characteristics. These methods provide high-resolution data on airflow patterns, enabling accurate quantification of tumble intensity and distribution within the intake manifold. Advanced CFD simulations complement experimental measurements by offering detailed insights into flow dynamics and aiding in manifold design optimization.

Innovations in Intake Manifold Design to Enhance Tumble

Innovations in intake manifold design, such as incorporating helical intake ports and variable valve timing, significantly enhance tumble motion to improve air-fuel mixing and combustion efficiency. Advanced computational fluid dynamics (CFD) enables precise optimization of port shape and runner length, promoting stronger tumble flow throughout the combustion chamber. These design enhancements reduce emissions and increase engine performance by ensuring a more homogeneous charge distribution and faster flame propagation.

Impact of Tumble Flow on Emissions and Performance

Tumble flow in the intake manifold enhances air-fuel mixture homogenization, resulting in more complete combustion and reduced hydrocarbon and particulate emissions. This improved combustion efficiency increases engine power output and responsiveness while lowering fuel consumption. Optimizing tumble flow promotes a stable flame front and faster burn rates, critical for meeting stringent emission regulations and achieving higher engine performance.

example of tumble in intake manifold Infographic

samplerz.com

samplerz.com