In automotive alignment, a shim is a thin, precisely measured piece of metal used to adjust the position of suspension components. Shims are inserted between mounting surfaces, such as between the control arm and the subframe, to correct camber, caster, or toe angles. This precise adjustment improves tire wear, handling, and overall vehicle stability. Alignment shims are critical in ensuring proper wheel alignment specifications are met according to manufacturer standards. The shims come in various thicknesses, often measured in millimeters, allowing technicians to achieve fine-tuned adjustments. Proper use of shims eliminates the need for costly parts replacement and maintains optimal suspension geometry for improved driving performance.

Table of Comparison

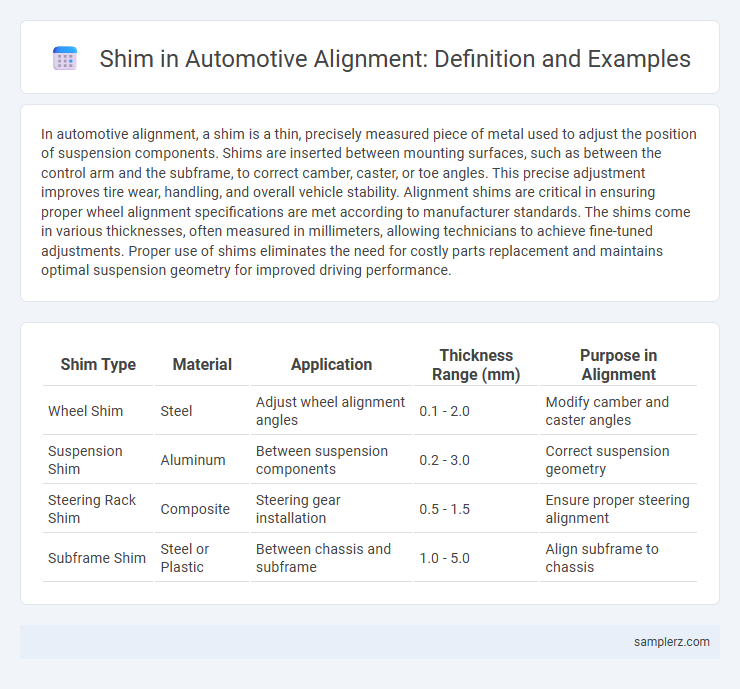

| Shim Type | Material | Application | Thickness Range (mm) | Purpose in Alignment |

|---|---|---|---|---|

| Wheel Shim | Steel | Adjust wheel alignment angles | 0.1 - 2.0 | Modify camber and caster angles |

| Suspension Shim | Aluminum | Between suspension components | 0.2 - 3.0 | Correct suspension geometry |

| Steering Rack Shim | Composite | Steering gear installation | 0.5 - 1.5 | Ensure proper steering alignment |

| Subframe Shim | Steel or Plastic | Between chassis and subframe | 1.0 - 5.0 | Align subframe to chassis |

Introduction to Shims in Automotive Alignment

Shims are thin, precisely engineered metal or composite spacers used in automotive alignment to adjust suspension geometry and ensure proper wheel angles. By inserting or removing shims between suspension components, technicians can fine-tune camber, caster, and toe settings, optimizing vehicle handling and tire wear. Commonly placed at control arm mounts or strut assemblies, shims enable accurate alignment without replacing major parts.

Common Types of Shims Used in Wheel Alignment

Common types of shims used in wheel alignment include camber shims, caster shims, and toe shims, each designed to adjust specific suspension angles for optimal tire contact and vehicle stability. Camber shims correct the tilt of the wheels inward or outward, improving tire wear and handling performance. Caster shims adjust the steering axis for better directional stability, while toe shims fine-tune the angle of the wheels in relation to the vehicle centerline, enhancing steering response.

Role of Shims in Adjusting Camber

Shims play a critical role in adjusting camber during vehicle wheel alignment by precisely altering the angle of the suspension components. By inserting or removing shims between the control arm and the mounting bracket, technicians can fine-tune the camber angle to ensure optimal tire contact and wear. Proper shim adjustment directly impacts vehicle handling, steering stability, and tire longevity in automotive suspension systems.

Using Shims for Correcting Caster Angles

Shims play a crucial role in correcting caster angles during vehicle wheel alignment by being strategically placed between the suspension components and the mounting points. This adjustment ensures proper wheel orientation, enhancing steering stability and tire wear distribution. Automotive technicians rely on specific shim thicknesses tailored to the vehicle model to achieve precise caster angle specifications.

Toe Adjustment Examples with Shims

Toe adjustment in automotive wheel alignment often involves the use of shims placed between suspension components to fine-tune the wheel angles. For example, inserting a 1mm shim behind the lower control arm can increase toe-in by approximately 0.1 degrees, improving tire wear and handling performance. Precise shim thickness selection directly impacts vehicle stability and alignment accuracy during maintenance.

Step-by-Step Guide to Installing Alignment Shims

Alignment shims are thin metal pieces used to adjust the camber and caster angles precisely during wheel alignment on vehicles. To install alignment shims, first lift the vehicle and safely remove the wheel and suspension components to access the control arm or strut mount where the shim will be placed. Next, insert the shim between the control arm and the mounting surface, then reassemble the suspension and wheel, ensuring the desired alignment angle is achieved before lowering the vehicle.

Signs That Indicate the Need for Alignment Shims

Uneven tire wear, such as excessive inner or outer edge abrasion, often signals the need for alignment shims to correct camber or caster angles. Steering wheel vibration or pulling to one side during driving also indicates misalignment that can be resolved by adjusting shims. Persistent handling issues, including poor vehicle stability and uneven steering response, highlight the necessity for precise shim placement in suspension components.

Alignment Shim Materials and Their Advantages

Alignment shims in automotive wheel alignments are commonly made from materials such as stainless steel, aluminum, and composite polymers, each offering specific benefits. Stainless steel shims provide high durability and corrosion resistance, ensuring long-lasting precision, while aluminum shims offer lightweight properties that minimize added weight to the suspension system. Composite polymer shims reduce friction and facilitate easy adjustments, contributing to improved alignment accuracy and enhanced vehicle handling.

Best Practices for Aligning Vehicles with Shims

Using shims in vehicle alignment ensures precise adjustment of suspension components, correcting camber and caster angles to manufacturer specifications. Best practices include selecting shims with exact thicknesses to avoid over-correction, rechecking alignment angles after installation, and using high-quality materials to prevent deformation under load. Proper shim application enhances handling, tire wear, and overall vehicle safety by maintaining optimal wheel alignment.

Case Studies: Real-World Alignment Corrections Using Shims

In a case study involving a 2018 Toyota Camry, precise alignment was achieved by inserting shim packs behind the strut mounts, correcting a 3mm camber deviation and improving tire wear patterns. Another example features a 2020 Ford F-150 where shims adjusted the caster angle by 1.5 degrees, restoring steering stability and reducing uneven tire wear. These real-world corrections demonstrate how shim installation plays a critical role in achieving factory-spec suspension alignment.

example of shim in alignment Infographic

samplerz.com

samplerz.com