A downdraft carburetor is a key automotive component that optimizes air-fuel mixture delivery to the engine by allowing air to flow downward through the carburetor. This design enhances fuel atomization and engine performance, especially in older vehicles with internal combustion engines. The downdraft mechanism relies on gravity and engine vacuum to draw the mixture into the intake manifold efficiently. In an automotive downdraft carburetor, the air enters through the top, passes through the venturi where it mixes with fuel, and then moves downward into the engine cylinders. This downward flow minimizes turbulence and improves throttle response, which is critical for engine power and efficiency. Common examples include the Weber 32/36 DGV and Holley 4150 models widely used in classic muscle cars and vintage trucks.

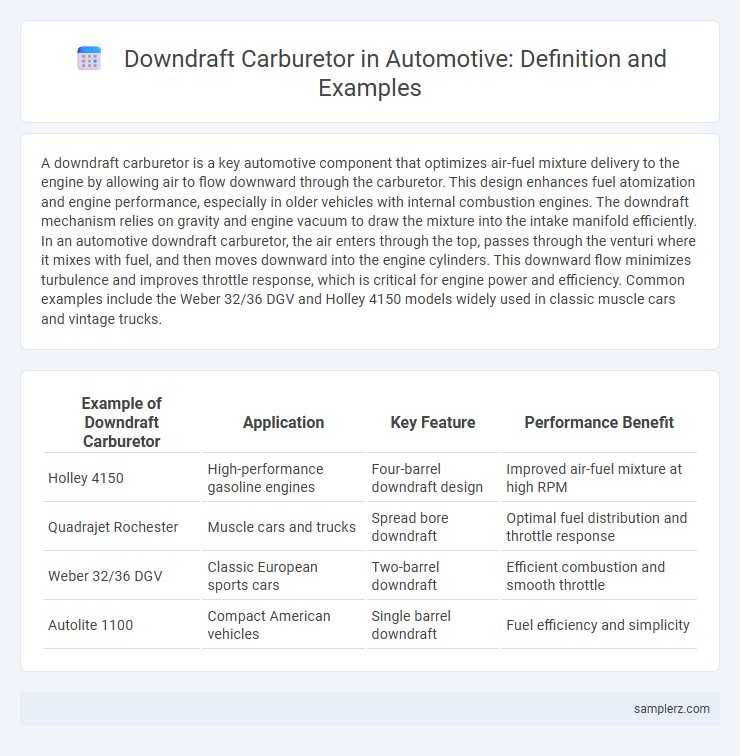

Table of Comparison

| Example of Downdraft Carburetor | Application | Key Feature | Performance Benefit |

|---|---|---|---|

| Holley 4150 | High-performance gasoline engines | Four-barrel downdraft design | Improved air-fuel mixture at high RPM |

| Quadrajet Rochester | Muscle cars and trucks | Spread bore downdraft | Optimal fuel distribution and throttle response |

| Weber 32/36 DGV | Classic European sports cars | Two-barrel downdraft | Efficient combustion and smooth throttle |

| Autolite 1100 | Compact American vehicles | Single barrel downdraft | Fuel efficiency and simplicity |

Understanding Downdraft Carburetors in Automotive Engineering

Downdraft carburetors are designed with a vertical air passage that directs airflow downward into the combustion chamber, improving fuel atomization and engine efficiency. This design promotes better air-fuel mixing by utilizing gravity and air velocity, leading to enhanced throttle response and power output in automotive engines. Understanding the principles of downdraft carburetors is essential for optimizing performance in classic and performance-oriented vehicles.

Core Principles of Downdraft Carburetor Operation

Downdraft carburetors utilize gravity and airflow to mix air and fuel efficiently, where air enters from above and moves downward through the venturi, creating a pressure drop that draws fuel into the airstream. The core principles include maintaining optimal air velocity for proper atomization and ensuring precise fuel metering through jets, which enhances combustion and engine performance. This design improves throttle response and fuel efficiency by promoting complete vaporization of the fuel-air mixture before entering the intake manifold.

Key Features of Downdraft Carburetor Designs

Downdraft carburetors feature a vertical airflow path that allows gravity to assist in fuel delivery, improving engine responsiveness and fuel atomization. Key design elements include a centrally located throttle plate for precise air-fuel mixture control and large venturi sizes to maximize air velocity and fuel mixing efficiency. This design enhances performance in high-speed engines by optimizing fuel distribution and minimizing flow resistance.

Classic Examples of Downdraft Carburetors

Classic examples of downdraft carburetors include the Holley 4-barrel and the Weber 40 DCOE series, both renowned for delivering efficient air-fuel mixture through vertical airflow. Downdraft carburetors position the throttle plate below the carburetor throat, ensuring gravity assists fuel atomization and improves engine breathing. Popular in muscle cars and European sports cars, these carburetors optimize fuel delivery for enhanced acceleration and throttle response.

Advantages of Downdraft Over Other Carburetor Types

Downdraft carburetors provide improved air-fuel mixture atomization due to gravity-assisted fuel flow, enhancing combustion efficiency and engine performance. Their vertical airflow design minimizes fuel pooling and reduces throttle response lag compared to sidedraft or updraft carburetors. This results in better fuel economy and cleaner emissions, making downdraft carburetors preferred in high-performance automotive applications.

Iconic Vehicles Utilizing Downdraft Carburetors

Iconic vehicles such as the Ford Mustang Boss 302 and Chevrolet Camaro Z28 prominently utilized downdraft carburetors, enhancing airflow efficiency and engine performance. These carburetors positioned the air intake above the throttle valves, allowing gravity-assisted fuel delivery and improved mixture atomization. The use of downdraft carburetors in muscle cars of the 1960s and 1970s contributed to their legendary power and throttle response.

Performance Benefits in Downdraft Carburetor Systems

Downdraft carburetor systems enhance engine performance by promoting smoother and more efficient air-fuel mixture flow directly into the combustion chamber, reducing turbulence and improving throttle response. This design increases volumetric efficiency, leading to better fuel atomization and combustion, which translates to higher power output and improved fuel economy. Downdraft carburetors are especially beneficial in high-performance engines where precise air-fuel delivery is critical.

Downdraft Carburetor Installation in Modern Vehicles

Downdraft carburetor installation in modern vehicles enhances air-fuel mixture efficiency by directing airflow downward through the carburetor, improving combustion and engine performance. This design reduces fuel droplet accumulation and ensures uniform distribution to the intake manifold, optimizing throttle response and power output. Modern adaptations integrate electronic controls to fine-tune the downdraft carburetor for better emissions and fuel economy compliance.

Maintenance Tips for Downdraft Carburetor Efficiency

Regularly clean the air filter and carburetor jets to prevent clogging and ensure optimal fuel-air mixture in downdraft carburetors. Inspect and adjust the throttle linkage and float level to maintain smooth engine performance and prevent fuel flooding. Using high-quality fuel and avoiding prolonged idling helps minimize deposits and prolong the carburetor's lifespan.

Comparing Downdraft vs. Sidedraft Carburetors in Automotive Applications

Downdraft carburetors direct air-fuel mixture vertically downward into the intake manifold, enhancing fuel atomization and engine efficiency by utilizing gravity and improved airflow dynamics. In contrast, sidedraft carburetors deliver the mixture horizontally, which can limit flow rate and is typically used in low-profile engine compartments. Downdraft designs generally provide superior throttle response and power output in automotive applications, making them preferred for high-performance and modern vehicles.

example of downdraft in carburetor Infographic

samplerz.com

samplerz.com