A knock sensor in an Engine Control Unit (ECU) is a critical automotive component designed to detect engine knocking or pinging. It typically uses a piezoelectric sensor attached to the engine block, which generates voltage signals when vibrations caused by knocking occur. The ECU processes these signals to adjust ignition timing and fuel injection, optimizing engine performance and preventing potential damage. In modern vehicles, the knock sensor enables real-time monitoring of combustion quality across various engine operating conditions. By analyzing data from the sensor, the ECU ensures efficient fuel combustion, reducing emissions and improving fuel economy. Integration of knock sensor data into the ECU enhances engine reliability and longevity by minimizing harmful detonation events.

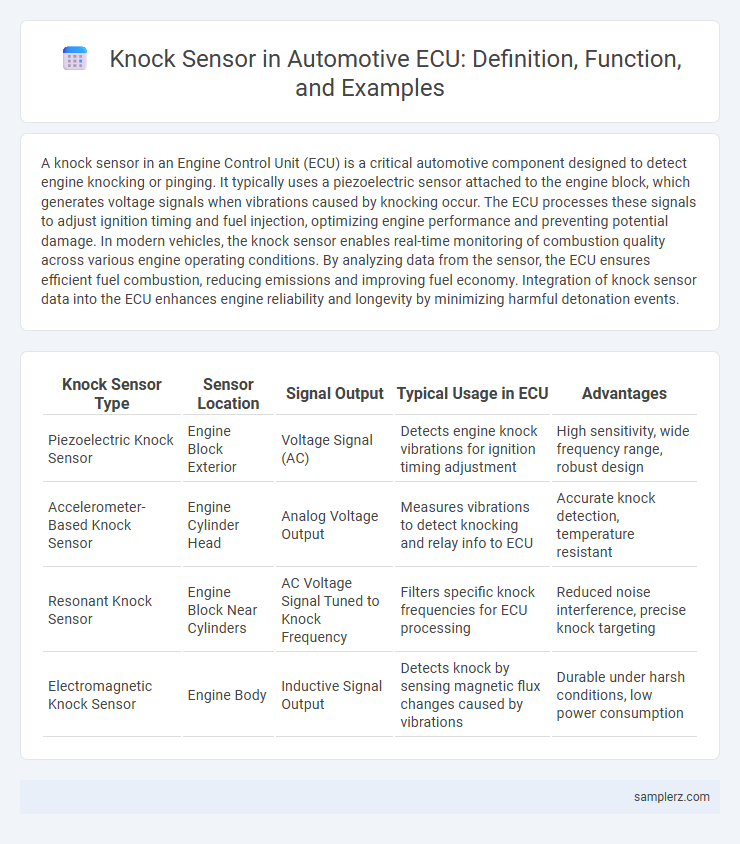

Table of Comparison

| Knock Sensor Type | Sensor Location | Signal Output | Typical Usage in ECU | Advantages |

|---|---|---|---|---|

| Piezoelectric Knock Sensor | Engine Block Exterior | Voltage Signal (AC) | Detects engine knock vibrations for ignition timing adjustment | High sensitivity, wide frequency range, robust design |

| Accelerometer-Based Knock Sensor | Engine Cylinder Head | Analog Voltage Output | Measures vibrations to detect knocking and relay info to ECU | Accurate knock detection, temperature resistant |

| Resonant Knock Sensor | Engine Block Near Cylinders | AC Voltage Signal Tuned to Knock Frequency | Filters specific knock frequencies for ECU processing | Reduced noise interference, precise knock targeting |

| Electromagnetic Knock Sensor | Engine Body | Inductive Signal Output | Detects knock by sensing magnetic flux changes caused by vibrations | Durable under harsh conditions, low power consumption |

Understanding the Role of the Knock Sensor in Automotive ECUs

The knock sensor in an automotive ECU detects engine knocking by sensing vibrations caused by abnormal combustion. It sends precise signals to the ECU, enabling real-time adjustments to ignition timing and fuel injection to prevent engine damage. This feedback loop enhances performance, fuel efficiency, and emission control by maintaining optimal combustion conditions.

How Knock Sensors Improve Engine Performance

Knock sensors detect abnormal vibrations caused by engine knocking and send real-time signals to the ECU, allowing precise ignition timing adjustments to prevent knock. This optimization enhances fuel efficiency and reduces harmful emissions while protecting engine components from damage. Modern knock sensors improve engine performance by enabling higher compression ratios and maximizing power output without sacrificing reliability.

Common Types of Knock Sensors Used in Modern Vehicles

Piezoelectric knock sensors are the most common type used in modern vehicles, converting high-frequency vibrations from engine knocking into electrical signals for the ECU. Resonant knock sensors, designed to detect specific frequencies related to knock events, enhance engine performance by allowing precise ignition timing adjustments. Some advanced ECUs utilize accelerometer-based sensors for more accurate detection and adaptation to various driving conditions.

Key Components of an ECU Knock Sensor System

The ECU knock sensor system in automotive engines primarily consists of a piezoelectric sensor designed to detect engine vibrations caused by knocking or detonation. This sensor converts mechanical vibrations into electrical signals, which the ECU analyzes to adjust ignition timing and optimize engine performance. Crucial components include the sensor itself, the signal conditioning circuit, and the ECU's processing unit that interprets knock signals to prevent engine damage.

Example: Integration of Knock Sensor in a Toyota ECU

The integration of a knock sensor in a Toyota ECU involves precise calibration to detect engine vibrations caused by abnormal combustion, preventing engine damage and optimizing performance. Toyota ECUs use knock sensor data to adjust ignition timing and fuel injection, enhancing fuel efficiency and reducing emissions. Advanced Toyota knock sensors operate within a specific frequency range to ensure accurate detection of engine knocking under various driving conditions.

Diagnostic Process for Knock Sensor Issues in ECUs

The diagnostic process for knock sensor issues in ECUs involves monitoring voltage fluctuations and signal patterns to detect abnormal knocking events that can damage the engine. Advanced ECUs utilize real-time data analysis and adaptive algorithms to isolate faulty knock sensor signals from engine noise, ensuring precise fault identification. Diagnostic trouble codes (DTCs) related to knock sensor malfunctions enable technicians to target sensor replacements or wiring repairs, optimizing engine performance and preventing potential damage.

Symptoms of a Faulty Knock Sensor in Automotive Applications

A faulty knock sensor in automotive applications can cause engine knocking or pinging, reduced fuel efficiency, and increased emissions. Drivers may experience poor acceleration, rough idling, or engine hesitation due to incorrect timing adjustments from the ECU. Diagnostic trouble codes such as P0325 often indicate knock sensor issues, requiring prompt replacement to maintain optimal engine performance.

Real-World Example: Knock Sensor Function in Honda Engines

Honda engines utilize knock sensors integrated within the ECU to detect abnormal combustion vibrations, preventing engine damage through real-time ignition timing adjustments. These piezoelectric sensors convert pressure fluctuations from engine knock into electrical signals, enabling precise control over fuel mixture and spark timing. For example, the Honda Civic's knock sensor system optimizes engine performance and fuel efficiency by minimizing detonation in varying driving conditions.

Benefits of Using Knock Sensors for Engine Longevity

Knock sensors in an Engine Control Unit (ECU) detect abnormal combustion or engine knocking, allowing real-time adjustments to ignition timing and fuel mixture. This precise monitoring protects the engine from damage caused by detonation, enhancing overall engine durability and performance. Implementing knock sensors significantly extends engine longevity by preventing excessive wear and maintaining optimal combustion conditions.

Future Trends: Advancements in Knock Sensor Technology for ECUs

Future advancements in knock sensor technology for ECUs will emphasize increased sensitivity and real-time adaptive learning algorithms to optimize engine performance and emissions control. Integration of MEMS-based knock sensors with AI-driven signal processing will enable precise detection of combustion anomalies under varying engine conditions. Enhanced connectivity through IoT-enabled ECUs will facilitate predictive maintenance and adaptive tuning, improving overall vehicle efficiency and longevity.

example of knock sensor in ECU Infographic

samplerz.com

samplerz.com