In the automotive industry, the term "squish" refers to the rapid movement of air-fuel mixture within the combustion chamber as the piston approaches top dead center. This squish effect occurs between the piston crown and the cylinder head, creating turbulence that enhances the mixing of fuel and air. Efficient squish improves combustion efficiency, reduces emissions, and increases engine performance. A common example of squish in a piston can be observed in high-performance engines where the piston crown and cylinder head are designed with precise clearances. The close proximity causes the mixture to rapidly compress, generating intense turbulence that promotes more complete combustion. Engine manufacturers often optimize squish zones through computer-aided design and testing to balance power output and emissions control.

Table of Comparison

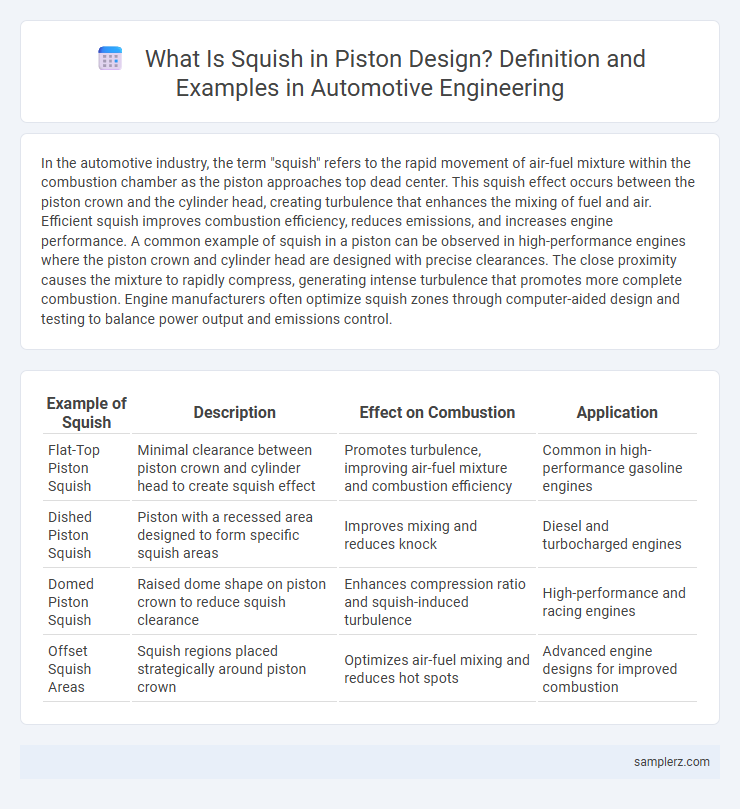

| Example of Squish | Description | Effect on Combustion | Application |

|---|---|---|---|

| Flat-Top Piston Squish | Minimal clearance between piston crown and cylinder head to create squish effect | Promotes turbulence, improving air-fuel mixture and combustion efficiency | Common in high-performance gasoline engines |

| Dished Piston Squish | Piston with a recessed area designed to form specific squish areas | Improves mixing and reduces knock | Diesel and turbocharged engines |

| Domed Piston Squish | Raised dome shape on piston crown to reduce squish clearance | Enhances compression ratio and squish-induced turbulence | High-performance and racing engines |

| Offset Squish Areas | Squish regions placed strategically around piston crown | Optimizes air-fuel mixing and reduces hot spots | Advanced engine designs for improved combustion |

Understanding Squish Effect in Pistons

Squish in pistons refers to the rapid movement of the air-fuel mixture toward the combustion chamber's center, enhancing turbulence and improving combustion efficiency. This effect increases flame speed and reduces emissions by promoting more complete fuel burn, especially in high-performance and lean-burn engines. Understanding the squish phenomenon helps engineers optimize piston crown design for better power output and reduced knock tendencies in modern automotive engines.

How Squish Zones Influence Combustion Efficiency

Squish zones in piston design create rapid air-fuel mixture turbulence by forcing the mixture toward the combustion chamber's center during compression. This enhanced turbulence improves fuel atomization and promotes faster, more complete combustion, resulting in increased thermal efficiency and lower emissions. Optimizing squish clearance and piston crown geometry directly influences combustion speed and stability, crucial for high-performance and low-emission engines.

Real-World Examples of Squish Designs in Modern Engines

Modern automotive engines utilize squish designs to enhance combustion efficiency by directing the air-fuel mixture towards the spark plug, promoting faster flame propagation. For instance, Honda's VTEC engines employ a piston crown with carefully engineered squish areas to maximize turbulence and improve fuel atomization. Similarly, Volkswagen's TSI engines integrate precise squish band clearances that reduce cycle-to-cycle variations, leading to higher power output and lower emissions.

Impact of Squish on Fuel-Air Mixing

Squish in a piston creates high-velocity turbulence that significantly improves fuel-air mixing within the combustion chamber, enhancing combustion efficiency and reducing emissions. This rapid mixing promotes more complete combustion of the air-fuel mixture, leading to better engine performance and lower fuel consumption. Optimizing squish geometry directly influences turbulence intensity, making it a critical factor in modern engine design for achieving cleaner and more efficient combustion.

Common Squish Area Configurations in Automotive Pistons

Common squish area configurations in automotive pistons include flat-top, dished, and dome-shaped designs that optimize combustion efficiency by promoting rapid air-fuel mixture turbulence. Flat-top pistons often feature a peripheral squish band that enhances flame propagation and reduces knock in high-performance engines. Dished pistons create a deep squish area that lowers compression ratio while improving swirl and turbulence, beneficial for emissions control in diesel engines.

Advantages of Squish in High-Performance Engines

Squish in high-performance engine pistons enhances combustion efficiency by promoting rapid and thorough air-fuel mixture turbulence, leading to improved flame propagation and reduced detonation risks. This increased turbulence results in more complete combustion, elevating power output and optimizing fuel consumption. Furthermore, squish zones contribute to better thermal management by dispersing heat evenly, which supports greater engine durability under high loads.

Case Study: Squish in Turbocharged Engines

Squish in turbocharged engines significantly enhances combustion efficiency by promoting rapid air-fuel mixing and reducing knock tendency. A case study on a turbocharged 2.0L direct-injection engine demonstrated that optimizing piston crown geometry to increase squish velocity led to a 7% improvement in thermal efficiency and a 15% reduction in NOx emissions. Computational fluid dynamics (CFD) analysis confirmed that the enhanced squish effect generated stronger turbulence near the spark plug, accelerating flame propagation and improving overall engine performance.

Squish Versus Quench: What’s the Difference?

Squish refers to the rapid movement of air-fuel mixture towards the combustion chamber walls as the piston approaches top dead center, creating turbulence that enhances combustion efficiency. Quench is the controlled reduction of temperature near the cylinder head and piston crown surfaces to prevent knocking and improve emissions. Understanding the difference between squish and quench is crucial for optimizing piston design and achieving better engine performance in automotive applications.

Challenges in Designing Effective Squish Zones

Designing effective squish zones in pistons presents challenges such as achieving optimal clearance between the piston crown and cylinder head to enhance combustion efficiency while preventing mechanical interference. Material selection and thermal expansion rates must be carefully considered to maintain squish integrity under high-temperature engine conditions. Balancing aerodynamic flow with combustion chamber volume is critical to reduce emissions and improve power output.

Future Trends in Squish Technology for Pistons

Future trends in squish technology for pistons emphasize enhanced combustion efficiency through optimized squish areas that promote better air-fuel mixing and faster flame propagation. Advanced computer-aided design (CAD) and simulation tools enable precise modeling of squish dynamics, resulting in reduced emissions and improved engine performance. Integration of lightweight materials and innovative surface coatings further contributes to durability and thermal management in next-generation pistons.

example of squish in piston Infographic

samplerz.com

samplerz.com