A wishbone in automotive suspension refers to a type of control arm shaped like a "V" or a "Y," commonly used in double wishbone suspension systems. This component connects the vehicle's chassis to the wheel hub, allowing controlled movement while maintaining wheel alignment. Materials such as steel or aluminum are often utilized for wishbones due to their strength and durability. The double wishbone suspension system employs upper and lower wishbones to provide precise handling and improved ride quality by controlling camber angles throughout wheel travel. This setup is prevalent in performance cars and off-road vehicles where suspension geometry is critical. Data shows that vehicles with double wishbone suspensions experience better cornering stability and tire wear compared to those with simpler suspension designs.

Table of Comparison

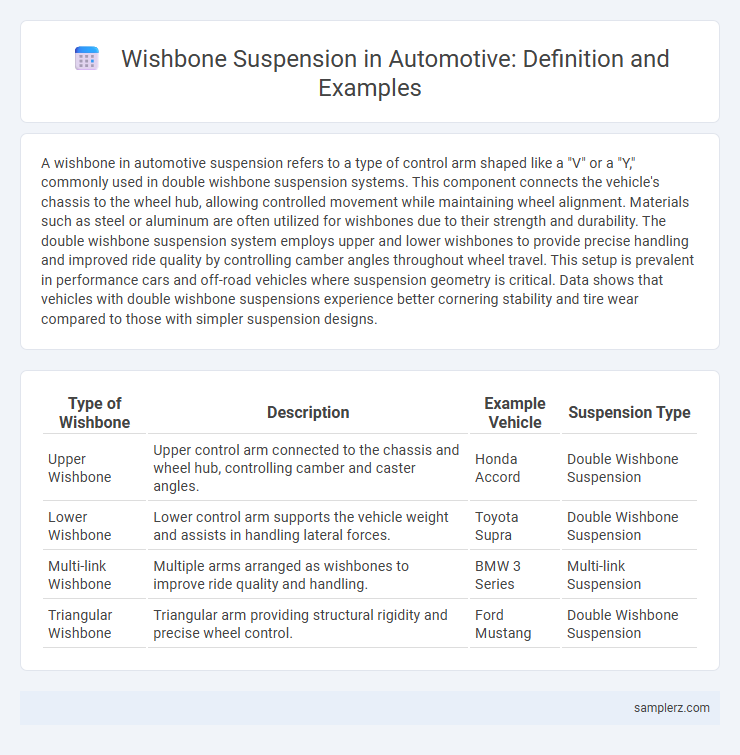

| Type of Wishbone | Description | Example Vehicle | Suspension Type |

|---|---|---|---|

| Upper Wishbone | Upper control arm connected to the chassis and wheel hub, controlling camber and caster angles. | Honda Accord | Double Wishbone Suspension |

| Lower Wishbone | Lower control arm supports the vehicle weight and assists in handling lateral forces. | Toyota Supra | Double Wishbone Suspension |

| Multi-link Wishbone | Multiple arms arranged as wishbones to improve ride quality and handling. | BMW 3 Series | Multi-link Suspension |

| Triangular Wishbone | Triangular arm providing structural rigidity and precise wheel control. | Ford Mustang | Double Wishbone Suspension |

Introduction to Wishbone Suspension in Automotives

Wishbone suspension, also known as double wishbone suspension, features two control arms shaped like a "V" or wishbone, providing precise wheel control and superior handling. Commonly used in sports cars and high-performance vehicles, this suspension system improves ride comfort and steering response by maintaining optimal tire contact through varied driving conditions. Key components include upper and lower wishbones, ball joints, and coil springs, working together to enhance stability and durability.

Key Components of a Wishbone Suspension System

A wishbone suspension system primarily consists of upper and lower control arms shaped like a wishbone, which connect the wheel hub to the vehicle chassis, providing precise wheel alignment and improved handling. Key components include ball joints that facilitate smooth pivoting, coil springs or torsion bars for absorbing shocks, and shock absorbers that dampen vibrations. This setup enhances ride comfort and stability by maintaining optimal tire contact with the road surface during various driving conditions.

Advantages of Wishbone Suspension Designs

Wishbone suspension designs offer superior control of wheel motion, enabling precise camber adjustment for improved tire contact and enhanced handling performance. Their compact geometry allows for reduced unsprung weight and better suspension articulation, resulting in increased ride comfort and stability. The robust, triangular structure provides excellent load distribution, minimizing stress on chassis components and extending vehicle durability.

Double Wishbone Suspension: Core Functions and Benefits

Double wishbone suspension uses two parallel arms mounted to the chassis, allowing precise control of wheel motion and alignment. This setup improves handling and tire wear by maintaining optimal camber through suspension travel, enhancing vehicle stability during cornering. It also absorbs road irregularities effectively, providing a smoother ride in both high-performance and everyday vehicles.

Real-World Applications: Cars Using Wishbone Suspensions

Many high-performance and luxury cars, such as the Toyota Crown and BMW 3 Series, utilize wishbone suspensions for improved handling and ride comfort. This suspension type offers precise wheel alignment and enhanced stability, crucial for sports cars and sedans navigating varying road conditions. Its real-world application extends to race cars like the McLaren F1, where lightweight construction and superior control are vital for optimal performance.

Comparison: Wishbone vs. MacPherson Strut Suspension

The wishbone suspension features two arms forming a triangular shape, offering superior control over wheel alignment and better handling during cornering compared to the MacPherson strut, which uses a single strut and coil spring assembly. While the wishbone design provides enhanced stability and durability in performance and off-road vehicles, the MacPherson strut suspension is more compact and cost-effective, making it popular in mass-produced passenger cars. Engineers often select wishbone setups for luxury and sports cars due to their ability to maintain optimal tire contact and improve ride quality under varying road conditions.

Performance Impact of Wishbone Suspension in Sports Cars

Wishbone suspension systems in sports cars enhance handling precision and cornering stability by providing optimal control over wheel alignment and camber angles. The double wishbone design allows for better tire contact with the road during aggressive maneuvers, significantly improving grip and responsiveness. This suspension type contributes to superior ride quality and reduced body roll, critical for high-performance driving dynamics.

Maintenance Tips for Wishbone Suspension Systems

Regular inspection of wishbone suspension components, such as ball joints, bushings, and control arms, ensures early detection of wear and tear, preventing costly repairs and maintaining vehicle stability. Lubricate all pivot points according to manufacturer specifications to reduce friction and prolong lifespan. Tightening all mounting bolts to the recommended torque settings maintains proper alignment and enhances overall suspension performance.

Common Issues Found in Wishbone Suspension Setups

Common issues in wishbone suspension setups include worn bushings that cause excessive play and noise, leading to reduced handling precision. Ball joint deterioration often results in uneven tire wear and compromised steering response, significantly affecting vehicle safety. Misalignment of the wishbones can cause uneven suspension geometry, reducing ride comfort and accelerating component wear.

Future Innovations in Wishbone Suspension Technology

Future innovations in wishbone suspension technology include adaptive materials such as carbon fiber composites and smart alloys that enhance strength while reducing weight. Integration of sensors and AI-driven control systems enables real-time adjustment of suspension geometry for optimal handling and comfort. Advanced manufacturing techniques like 3D printing allow for complex, customized wishbone designs that improve durability and performance in electric and autonomous vehicles.

example of wishbone in suspension Infographic

samplerz.com

samplerz.com