In automotive engineering, tumble in the air-fuel mixture refers to the rapid rotational motion of the intake charge within the combustion chamber. This phenomenon is crucial for enhancing fuel atomization and ensuring a more uniform air-fuel distribution, which leads to efficient combustion. Tumble motion is generated by specific intake port designs and combustion chamber shapes that direct the mixture in a vertical swirling pattern. Engine manufacturers use tumble to improve engine performance and reduce emissions by promoting faster and more complete combustion. High tumble ratios contribute to better stability of the mixture at low engine speeds, facilitating smooth idling and throttle response. Data from experimental engine testing often show a direct correlation between increased tumble intensity and improved fuel economy, making it a key parameter in engine design optimization.

Table of Comparison

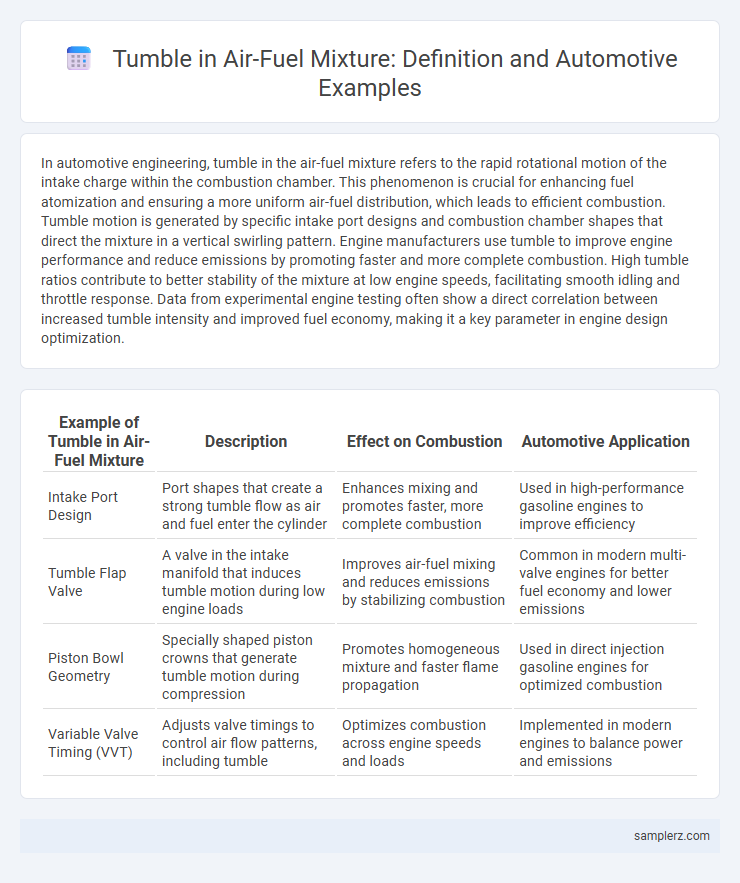

| Example of Tumble in Air-Fuel Mixture | Description | Effect on Combustion | Automotive Application |

|---|---|---|---|

| Intake Port Design | Port shapes that create a strong tumble flow as air and fuel enter the cylinder | Enhances mixing and promotes faster, more complete combustion | Used in high-performance gasoline engines to improve efficiency |

| Tumble Flap Valve | A valve in the intake manifold that induces tumble motion during low engine loads | Improves air-fuel mixing and reduces emissions by stabilizing combustion | Common in modern multi-valve engines for better fuel economy and lower emissions |

| Piston Bowl Geometry | Specially shaped piston crowns that generate tumble motion during compression | Promotes homogeneous mixture and faster flame propagation | Used in direct injection gasoline engines for optimized combustion |

| Variable Valve Timing (VVT) | Adjusts valve timings to control air flow patterns, including tumble | Optimizes combustion across engine speeds and loads | Implemented in modern engines to balance power and emissions |

Introduction to Tumble in Automotive Air-Fuel Mixture

Tumble in the automotive air-fuel mixture refers to the rotational motion of the air-fuel charge perpendicular to the cylinder axis, promoting better mixing and combustion efficiency. This phenomenon enhances flame propagation and reduces emissions by improving fuel atomization and air distribution within the combustion chamber. Modern engine designs optimize tumble flow through intake port geometry and variable valve timing to maximize performance and fuel economy.

What Is Tumble Motion in Combustion Chambers?

Tumble motion in combustion chambers refers to the rotational airflow pattern where the air-fuel mixture spins around a horizontal axis, enhancing in-cylinder mixing and combustion efficiency. This tumbling effect improves flame propagation speed, reduces emissions, and promotes more stable combustion by creating better turbulence during the intake stroke. Optimized tumble motion is crucial in modern engines, contributing to higher power output and improved fuel economy.

Importance of Tumble Flow for Engine Efficiency

Tumble flow in the air-fuel mixture enhances combustion efficiency by promoting better air-fuel mixing and faster flame propagation inside the combustion chamber. This flow pattern increases turbulence, leading to more complete fuel burning and reduced emissions. Optimizing tumble flow in gasoline engines significantly improves power output and fuel economy while lowering pollutant formation.

How Tumble Enhances Air-Fuel Mixing

Tumble motion in the air-fuel mixture enhances combustion efficiency by creating a rotating airflow pattern that promotes intense turbulence and better atomization of fuel droplets. This increased turbulence improves the homogeneity of the mixture, enabling faster and more complete combustion, which leads to reduced emissions and improved engine performance. Optimizing tumble flow in combustion chambers is critical for achieving higher thermal efficiency and meeting stringent emission regulations in modern automotive engines.

Types of Tumble: Axial vs. Lateral Motion

Tumble in air-fuel mixture occurs as a rotational motion of the charge within the combustion chamber, significantly influencing combustion quality and engine efficiency. Axial tumble involves rotation around the engine's cylinder axis, promoting enhanced mixing and faster flame propagation along the cylinder height. Lateral tumble, rotating perpendicular to the cylinder axis, improves fuel-air homogenization by inducing swirl-like motion, which effectively stabilizes the combustion process and reduces emissions.

Real-World Examples of Tumble in Engine Design

Tumble motion in the air-fuel mixture enhances combustion efficiency by promoting better mixing and faster flame propagation, crucial in modern gasoline engines like Volkswagen's TSI series. Engine designs incorporating tumble flow features, such as specially shaped intake ports and cylinder heads in Honda's Earth Dreams Technology, demonstrate reduced emissions and improved fuel economy. Advanced CFD simulations in Toyota's Dynamic Force Engines validate how optimized tumble enhances power output while maintaining low particulate formation.

Cylinder Head and Intake Port Effects on Tumble

The design of the cylinder head and intake port significantly influences tumble motion within the air-fuel mixture, enhancing combustion efficiency by promoting better swirl and mixing. Cylinder heads with specifically shaped intake ports create a strong tumble flow that improves the air-fuel homogeneity entering the combustion chamber. This controlled tumble reduces knock tendency, increases thermal efficiency, and lowers emissions in modern internal combustion engines.

Measurement and Visualization of Tumble Motion

Measurement and visualization of tumble motion in air-fuel mixtures are crucial for optimizing combustion efficiency in internal combustion engines. Techniques such as Particle Image Velocimetry (PIV) and Laser Doppler Anemometry (LDA) enable detailed capture of tumble flow patterns, providing data on velocity fields and turbulence intensity. These measurements assist engineers in refining intake port designs and fuel injection strategies to enhance mixture homogeneity and reduce emissions.

Impact of Tumble on Emissions and Power Output

Tumble in the air-fuel mixture enhances combustion efficiency by promoting better fuel atomization and faster flame propagation, leading to reduced incomplete combustion emissions such as hydrocarbons (HC) and carbon monoxide (CO). Improved tumble flow increases turbulence intensity, contributing to higher power output through more complete burning of the air-fuel mixture. Optimized tumble motion also helps lower nitrogen oxide (NOx) emissions by enabling combustion at lower peak temperatures.

Innovations and Advances in Tumble Control Technologies

Advanced tumble control technologies enhance the air-fuel mixture dynamics by optimizing in-cylinder flow patterns, resulting in improved combustion efficiency and reduced emissions. Innovations such as variable valve timing, swirled intake ports, and active intake manifold systems enable precise manipulation of tumble motion to promote better fuel atomization and faster flame propagation. Current research emphasizes integrating real-time sensors and adaptive control algorithms to dynamically adjust tumble intensity, maximizing engine performance and meeting stringent emissions standards.

example of tumble in air-fuel mixture Infographic

samplerz.com

samplerz.com