Unsprung mass in an automotive wheel refers to the components not supported by the vehicle's suspension system. This includes the wheel hub, tire, brake assemblies, and portions of the axle. Reducing unsprung mass improves ride quality and handling by allowing the suspension to better respond to road irregularities. The weight of the brake disc, caliper, and wheel itself contributes significantly to unsprung mass. Engineers focus on lightweight materials such as aluminum alloys and carbon fiber to minimize this mass. Optimizing unsprung mass can enhance traction, braking performance, and overall vehicle dynamics.

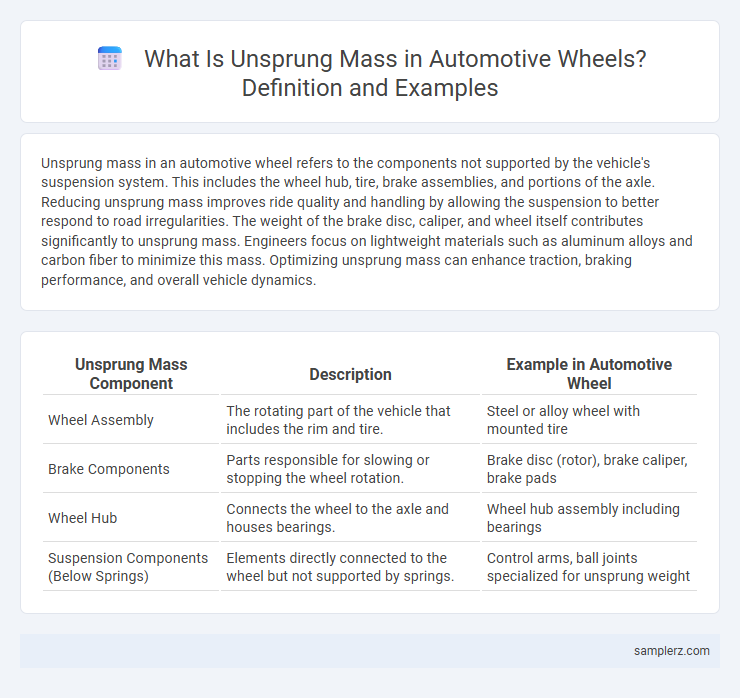

Table of Comparison

| Unsprung Mass Component | Description | Example in Automotive Wheel |

|---|---|---|

| Wheel Assembly | The rotating part of the vehicle that includes the rim and tire. | Steel or alloy wheel with mounted tire |

| Brake Components | Parts responsible for slowing or stopping the wheel rotation. | Brake disc (rotor), brake caliper, brake pads |

| Wheel Hub | Connects the wheel to the axle and houses bearings. | Wheel hub assembly including bearings |

| Suspension Components (Below Springs) | Elements directly connected to the wheel but not supported by springs. | Control arms, ball joints specialized for unsprung weight |

Understanding Unsprung Mass in Automotive Wheels

Unsprung mass in automotive wheels refers to the components not supported by the vehicle's suspension, including the wheel, tire, brake assemblies, and a portion of the axle. Reducing unsprung mass improves ride quality and handling by allowing the suspension to respond more effectively to road irregularities. Advanced materials such as aluminum alloys and carbon fiber composites are commonly used to minimize unsprung weight in modern vehicles.

Common Examples of Unsprung Mass Components

Common examples of unsprung mass components in automotive wheels include the wheel hub, brake calipers, and the wheel itself, which directly affect vehicle handling and ride comfort. Suspension components such as control arms and the axle shafts also contribute to unsprung mass, influencing the dynamic response of the wheel assembly. Reducing unsprung mass improves traction, reduces tire wear, and enhances overall driving performance.

The Role of Tires as Unsprung Mass

Tires constitute a significant portion of the unsprung mass in a wheel assembly, directly affecting vehicle handling and ride comfort. Their weight influences the suspension's ability to absorb road irregularities, with heavier tires increasing unsprung mass and reducing responsiveness. Optimizing tire weight through advanced materials enhances traction and overall suspension performance by minimizing the unsprung mass impact.

How Wheel Assemblies Contribute to Unsprung Weight

Wheel assemblies significantly contribute to unsprung weight through components like the wheel rim, tire, brake rotor, and hub assembly, which collectively impact vehicle handling and ride quality. Heavier unsprung mass reduces suspension responsiveness, causing decreased traction and increased tire wear. Engineering efforts focus on lightweight materials such as aluminum and carbon fiber to minimize unsprung weight in wheel assemblies, enhancing overall vehicle performance and comfort.

Brake Discs and Calipers: Key Unsprung Elements

Brake discs and calipers are critical components of unsprung mass in automotive wheels, directly affecting vehicle handling and ride quality. The weight of these elements influences suspension responsiveness and traction by adding to the unsprung mass, which impacts the wheel's ability to maintain contact with the road surface. Optimizing the materials and design of brake discs and calipers can reduce unsprung mass, enhancing braking performance and overall driving dynamics.

The Impact of Wheel Hubs on Unsprung Mass

Wheel hubs play a critical role in the unsprung mass of a vehicle, directly affecting ride quality and handling performance. Heavier wheel hubs increase unsprung mass, leading to reduced suspension responsiveness and diminished traction on uneven surfaces. Optimizing wheel hub design with lightweight materials such as aluminum or carbon fiber can significantly lower unsprung mass, enhancing vehicle dynamics and overall driving comfort.

Suspension Linkages as Part of Unsprung Assembly

Suspension linkages, including control arms and tie rods, are key components of the unsprung mass in automotive wheel assemblies. These linkages directly affect vehicle handling and ride comfort by transmitting forces between the wheel and chassis. Reducing unsprung mass in suspension linkages improves responsiveness and minimizes vibrations, enhancing overall driving dynamics.

Driveshafts and Their Contribution to Unsprung Mass

Driveshafts significantly contribute to the unsprung mass of a vehicle's wheel assembly by transmitting torque from the transmission to the wheels. Heavier driveshafts increase unsprung mass, negatively affecting suspension performance and ride quality by reducing the system's ability to absorb road irregularities. Advanced materials like carbon fiber and hollow steel shafts are engineered to minimize driveshaft weight, thereby optimizing unsprung mass and improving overall vehicle dynamics.

Effects of Unsprung Mass on Vehicle Performance

Unsprung mass in a vehicle typically includes components such as the wheel, tire, brake assembly, and part of the suspension directly connected to the wheel. Increased unsprung mass negatively affects vehicle performance by reducing ride comfort, as heavier unsprung components are less able to respond quickly to road surface irregularities. This results in diminished traction, poorer handling, and increased tire wear due to less effective absorption of shocks from uneven terrain.

Strategies to Reduce Unsprung Mass in Wheels

Reducing unsprung mass in automotive wheels enhances suspension responsiveness and overall vehicle handling. Strategies include using lightweight materials such as aluminum alloys or carbon fiber composites for wheel construction and employing hollow or thin-walled brake rotors to minimize weight. Advanced manufacturing techniques like flow forming and replacing traditional steel components with forged alternatives also contribute to lowering unsprung mass for improved ride quality and performance.

example of unsprung mass in wheel Infographic

samplerz.com

samplerz.com