In automotive engineering, a bellhousing is a critical component that encases the flywheel and clutch assembly, providing a secure connection between the engine and the gearbox. The bellhousing's design varies depending on the vehicle make and model, with common materials including cast aluminum or cast iron for durability and heat resistance. One notable example is the Toyota Corolla's bellhousing, which integrates with its 5-speed manual transmission to ensure precise alignment and optimal power transfer. The bellhousing's role extends to protecting internal transmission parts from dirt and debris while facilitating easy inspection and maintenance. In performance vehicles, aftermarket bellhousings made from lightweight alloys are popular for reducing overall drivetrain weight and improving heat dissipation. Data from automotive manufacturers show that properly designed bellhousings contribute to enhanced gearbox longevity and smoother gear shifts by maintaining consistent alignment between engine and transmission components.

Table of Comparison

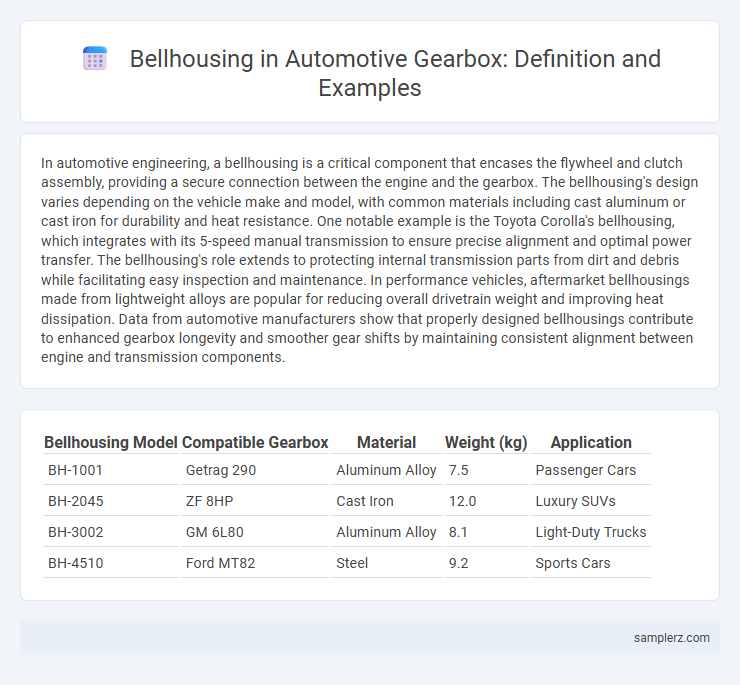

| Bellhousing Model | Compatible Gearbox | Material | Weight (kg) | Application |

|---|---|---|---|---|

| BH-1001 | Getrag 290 | Aluminum Alloy | 7.5 | Passenger Cars |

| BH-2045 | ZF 8HP | Cast Iron | 12.0 | Luxury SUVs |

| BH-3002 | GM 6L80 | Aluminum Alloy | 8.1 | Light-Duty Trucks |

| BH-4510 | Ford MT82 | Steel | 9.2 | Sports Cars |

Introduction to Bellhousing in Automotive Gearbox

The bellhousing in an automotive gearbox serves as a protective casing that encases the clutch assembly and connects the engine to the transmission. Typically constructed from cast aluminum or steel, the bellhousing ensures precise alignment between the engine crankshaft and the transmission input shaft, which is critical for smooth power transfer and minimizing wear. Modern bellhousings may also integrate sensor mounts and support for starter motors, highlighting their essential role in drivetrain performance and reliability.

Definition and Function of Bellhousing

A bellhousing in a gearbox is a bell-shaped metal casing that connects the engine to the transmission, enclosing the clutch assembly and flywheel. Its primary function is to protect these critical components from dirt, debris, and damage while ensuring proper alignment between the engine and transmission shafts. This alignment is essential for efficient power transfer and smooth vehicle operation in automotive drivetrains.

Common Materials Used for Bellhousing Construction

Bellhousings in automotive gearboxes are commonly constructed from cast aluminum and cast iron due to their excellent strength-to-weight ratios and thermal conductivity. Aluminum bellhousings offer lightweight properties that enhance fuel efficiency and reduce overall vehicle weight, while cast iron variants provide superior durability and resistance to mechanical stress. Advanced composites and magnesium alloys are also emerging materials, favored for their high strength and lighter mass in performance and racing applications.

Bellhousing Position Within the Gearbox Assembly

The bellhousing is positioned at the front of the gearbox assembly, encasing the flywheel and clutch components while providing a mounting point for the starter motor. It serves as a critical interface between the engine and transmission, ensuring proper alignment and secure attachment. Precision in the bellhousing's placement directly impacts drivetrain efficiency and overall vehicle performance.

Popular Examples of Bellhousing Designs

Popular examples of bellhousing designs in automotive gearboxes include the Aisin and ZF units, widely used in performance and heavy-duty applications for their robust construction and efficient power transfer. Modular bellhousings from manufacturers like Tremec allow easy adaptability across various engine and transmission configurations, optimizing maintenance and upgrades. Lightweight aluminum bellhousings are favored in racing vehicles to reduce weight while maintaining structural integrity and heat dissipation.

Bellhousing Applications in Manual vs. Automatic Transmissions

Bellhousing connects the engine to the transmission, providing a secure encasement for the clutch in manual transmissions and the torque converter in automatic transmissions. In manual gearboxes, bellhousings must accommodate clutch mechanisms and release forks, whereas automatic transmission bellhousings integrate with hydraulic systems for torque converter operation. This critical component ensures precise alignment and efficient power transfer between the engine and transmission across different vehicle drivetrains.

Identifying Bellhousing Types by Vehicle Brand

Bellhousing types vary significantly among vehicle brands due to differences in engine and transmission designs, with manufacturers like Ford commonly using cast iron bellhousings for durability, while General Motors often employs aluminum for weight reduction. Japanese brands such as Toyota and Honda typically feature bellhousings integrated into the transmission casing, optimizing space and production efficiency. European manufacturers like BMW and Volkswagen tend to utilize modular bellhousing designs to accommodate multiple engine variants and enhance repair flexibility.

Aftermarket and Performance Bellhousing Options

Aftermarket and performance bellhousing options in automotive gearboxes offer enhanced durability and precision fitments tailored for high-performance applications. Popular brands like Fidanza and McLeod provide lightweight aluminum bellhousings designed to improve power transfer and reduce overall drivetrain weight. These bellhousings often feature reinforced mounting points compatible with a wide range of manual and automatic transmissions, ensuring seamless integration in custom builds and racing setups.

Signs of Bellhousing Failure in Gearboxes

Signs of bellhousing failure in gearboxes include unusual vibrations during gear shifts, visible cracks or corrosion on the housing surface, and oil leaks around the bellhousing area. Excessive noise or difficulty in gear engagement can indicate misalignment or structural damage within the bellhousing. Early detection of these symptoms is crucial to prevent further transmission damage and costly repairs.

Maintenance Tips for Gearbox Bellhousing

Regularly inspect the gearbox bellhousing for cracks, corrosion, and wear to prevent costly failures and ensure alignment with the engine. Apply proper torque specifications when tightening bolts to maintain structural integrity and avoid vibrations that can damage internal components. Clean the bellhousing surface thoroughly before reassembly to remove debris and contaminants that may affect sealing and performance.

example of bellhousing in gearbox Infographic

samplerz.com

samplerz.com