In the automotive industry, a plenum in the intake system is a central chamber that distributes air evenly to the engine's cylinders. This component helps optimize airflow, ensuring better combustion efficiency and engine performance. Many modern internal combustion engines utilize plenums to reduce air pressure fluctuations and improve throttle response. One common example of a plenum in the intake system is found in multi-point fuel injection setups. The plenum collects air after the throttle body and channels it through intake runners to each cylinder. Data shows that well-designed plenums can increase horsepower and torque by providing smooth, consistent airflow.

Table of Comparison

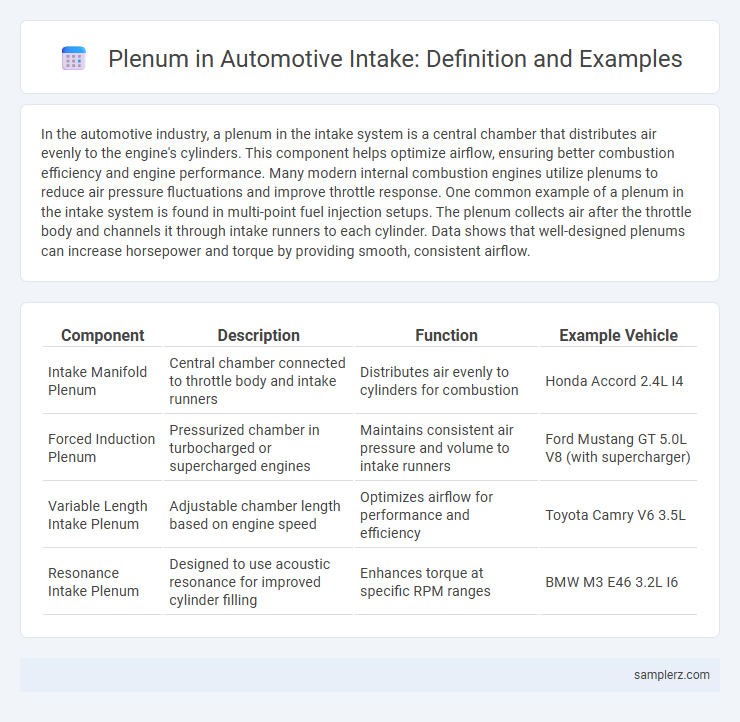

| Component | Description | Function | Example Vehicle |

|---|---|---|---|

| Intake Manifold Plenum | Central chamber connected to throttle body and intake runners | Distributes air evenly to cylinders for combustion | Honda Accord 2.4L I4 |

| Forced Induction Plenum | Pressurized chamber in turbocharged or supercharged engines | Maintains consistent air pressure and volume to intake runners | Ford Mustang GT 5.0L V8 (with supercharger) |

| Variable Length Intake Plenum | Adjustable chamber length based on engine speed | Optimizes airflow for performance and efficiency | Toyota Camry V6 3.5L |

| Resonance Intake Plenum | Designed to use acoustic resonance for improved cylinder filling | Enhances torque at specific RPM ranges | BMW M3 E46 3.2L I6 |

Understanding the Role of an Intake Plenum

An intake plenum serves as a critical component in an automotive engine by evenly distributing air to the cylinders, enhancing combustion efficiency and engine performance. Its design optimizes airflow and pressure within the intake manifold, reducing turbulence and improving volumetric efficiency. Effective intake plenum configurations contribute to better throttle response and increased power output in internal combustion engines.

What is an Intake Plenum in Automotive Engines?

An intake plenum in automotive engines serves as a crucial air distribution chamber, evenly channeling air to the intake manifold runners and improving cylinder filling efficiency. Typically made from lightweight materials such as aluminum or composite plastics, the plenum reduces air turbulence and enhances volumetric efficiency for better engine performance. Its design directly influences airflow dynamics, throttle response, and overall combustion quality in internal combustion engines.

Key Functions of the Intake Plenum

The intake plenum in automotive engines serves as a crucial air distribution chamber, ensuring uniform airflow to each cylinder for optimal combustion efficiency. It regulates volumetric efficiency by maintaining consistent air pressure and smoothing airflow pulses from the throttle body. This results in enhanced engine performance, improved fuel economy, and reduced emissions.

Types of Intake Plenums Used in Cars

Automotive intake plenums vary primarily between single-plane and dual-plane designs, each optimizing air distribution to engine cylinders for different performance goals. Single-plane plenums feature a large, open design that supports high RPM horsepower by offering equal-length runners, while dual-plane plenums split airflow into two separate chambers to enhance low-end torque and fuel efficiency. Advanced variations include variable-length intake plenums that adjust runner lengths dynamically, promoting both power and efficiency across a wider engine speed range.

Example of OEM Intake Plenum Designs

OEM intake plenum designs in automotive engineering optimize airflow distribution to each cylinder, enhancing engine efficiency and performance. For example, BMW's intake plenum features variable length runners that adapt to engine speed, improving torque and throttle response. Similarly, Audi implements acoustic tuning within their plenum chambers to reduce intake noise while maximizing volumetric efficiency.

Performance Intake Plenum: Key Features and Benefits

The Performance Intake Plenum optimizes air distribution to each cylinder, enhancing engine breathing efficiency and boosting horsepower. Engineered with lightweight materials and aerodynamic design, it reduces turbulence, ensuring a consistent and high-volume airflow for improved throttle response. This results in increased torque, better fuel atomization, and overall enhanced engine performance.

Case Study: Plenum Design in Sports Cars

The plenum in sports car intake systems is engineered to optimize air distribution for high-performance engines, ensuring consistent air pressure across all cylinders to enhance power and throttle response. Case studies reveal that variable-volume plenums, integrated with tuned runners, significantly improve turbocharged engines' efficiency by minimizing pressure losses at high RPMs. Advanced computational fluid dynamics (CFD) simulations highlight how precision-designed plenum shapes contribute to maximizing volumetric efficiency and reducing turbo lag in sports car applications.

Common Materials Used for Intake Plenums

Intake plenums in automotive engines are commonly manufactured from aluminum due to its lightweight and excellent heat dissipation properties, enhancing engine performance. Composite materials such as reinforced nylon and carbon fiber are also prevalent, offering high strength-to-weight ratios and resistance to heat and corrosion. These materials contribute to improved airflow efficiency and increased durability in demanding engine environments.

Plenum Upgrade Examples for Enhanced Performance

Upgrading the intake plenum can significantly enhance engine performance by improving airflow distribution and increasing volumetric efficiency. Common plenum upgrades include enlarging the plenum chamber, smoothing internal surfaces, and optimizing runner length to reduce turbulence and boost air velocity. High-performance aftermarket plenums often feature lightweight materials and precision-engineered designs tailored for increased horsepower and throttle response.

Maintenance Tips for Intake Plenums

Regular inspection of the intake plenum ensures optimal airflow and prevents carbon buildup that can reduce engine performance. Using high-quality air filters and replacing them on schedule minimizes contaminants entering the plenum, extending its lifespan. Applying specialized cleaning agents during routine maintenance removes deposits without damaging the plenum's internal surfaces.

example of plenum in intake Infographic

samplerz.com

samplerz.com