A trunnion in a driveshaft serves as a pivotal component that supports rotational movement while maintaining alignment between the shaft and the connected parts. Typically, the trunnion consists of a robust, cylindrical pin that fits into bearing sockets on the driveshaft yoke, enabling smooth torque transmission. This design is crucial for accommodating angular changes and absorbing vibrations in the drivetrain system. In automotive applications, trunnions are essential in slip yokes and universal joints of the driveshaft assembly, ensuring flexibility and durability under varying load conditions. Data shows that vehicles equipped with trunnion-based driveshafts experience improved operational stability and reduced wear on drivetrain components compared to rigid shaft assemblies. Engineers focus on high-strength materials like forged steel for trunnions to enhance lifespan and resistance to mechanical stress.

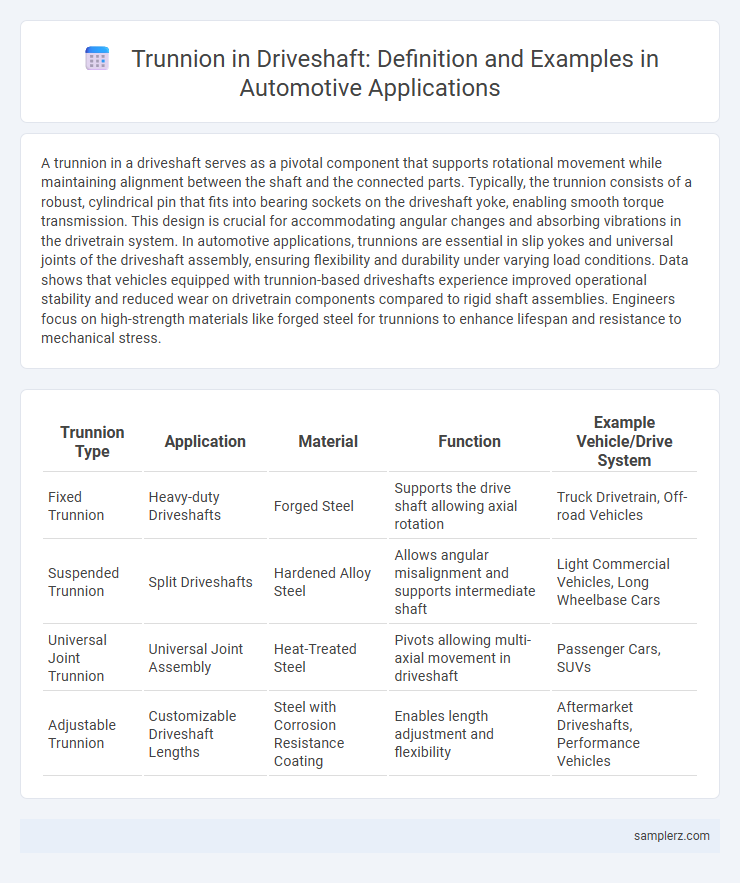

Table of Comparison

| Trunnion Type | Application | Material | Function | Example Vehicle/Drive System |

|---|---|---|---|---|

| Fixed Trunnion | Heavy-duty Driveshafts | Forged Steel | Supports the drive shaft allowing axial rotation | Truck Drivetrain, Off-road Vehicles |

| Suspended Trunnion | Split Driveshafts | Hardened Alloy Steel | Allows angular misalignment and supports intermediate shaft | Light Commercial Vehicles, Long Wheelbase Cars |

| Universal Joint Trunnion | Universal Joint Assembly | Heat-Treated Steel | Pivots allowing multi-axial movement in driveshaft | Passenger Cars, SUVs |

| Adjustable Trunnion | Customizable Driveshaft Lengths | Steel with Corrosion Resistance Coating | Enables length adjustment and flexibility | Aftermarket Driveshafts, Performance Vehicles |

Understanding the Role of Trunnions in Driveshafts

Trunnions in driveshafts serve as pivotal mounting points that enable rotational movement while maintaining axial alignment between components. These cylindrical bearings absorb torque and accommodate angular misalignment, ensuring smooth transmission of power from the engine to the wheels. Proper function of trunnions reduces vibrations, minimizes wear on the driveshaft assembly, and enhances overall vehicle drivetrain performance.

Key Components of a Driveshaft Trunnion Assembly

The driveshaft trunnion assembly includes key components such as the yoke, which connects the driveshaft to the differential, and the bearing housing that supports rotational movement while minimizing friction. The universal joint, integrated within the trunnion, allows for angular displacement and flexibility between driveline sections. High-strength steel or alloy materials are typically used to enhance durability and withstand torsional stress during vehicle operation.

Types of Trunnions Used in Automotive Driveshafts

Automotive driveshafts commonly use slip yoke trunnions, fixed yoke trunnions, and double-cardan trunnions to accommodate angular movement and torque transmission. Slip yoke trunnions enable telescoping action for length changes during suspension travel, while fixed yoke trunnions provide rigid connection points for rotational stability. Double-cardan trunnions combine two universal joints for smoother power delivery at higher operating angles, reducing vibration and wear.

Example of Universal Joint Trunnion in Driveshafts

The universal joint trunnion in driveshafts serves as a critical pivot point that allows for angular movement between the driveshaft and the connected components, optimizing torque transmission in vehicles. In heavy-duty trucks, the trunnion typically consists of hardened steel bearings mounted within a cross-shaped forging, enabling durability and smooth articulation under high-stress conditions. Precision engineering of the trunnion assembly reduces vibration and wear, enhancing drivetrain efficiency and vehicle performance.

Crucial Functions of Trunnion Bearings in Driveshaft Systems

Trunnion bearings in driveshaft systems play a crucial role by supporting the driveshaft and allowing smooth rotational movement under varying loads and angles. These bearings absorb and distribute stresses, enhancing drivetrain durability and reducing vibration and noise for improved vehicle performance. Proper maintenance of trunnion bearings is essential to prevent premature wear and ensure the driveshaft's reliable operation.

Materials Commonly Used for Driveshaft Trunnions

Driveshaft trunnions commonly utilize high-strength steel alloys such as 4340 and 300M for their excellent fatigue resistance and toughness. Aluminum alloys like 7075 are also used to reduce weight while maintaining adequate strength in performance vehicles. Advanced materials like carbon fiber composites are emerging for trunnions, offering superior stiffness and corrosion resistance in high-end automotive applications.

Maintenance Tips for Driveshaft Trunnion Longevity

Regularly inspect the driveshaft trunnion for signs of wear, such as excessive play or corrosion, to prevent premature failure. Apply appropriate lubricants according to manufacturer specifications to reduce friction and avoid rust buildup. Replace worn or damaged trunnion bearings promptly to maintain driveshaft alignment and ensure smooth vehicle operation.

Signs of Worn or Damaged Driveshaft Trunnion

Worn or damaged driveshaft trunnions often exhibit excessive vibration, clunking noises during acceleration or deceleration, and visible wear or rust around the joint area. These symptoms indicate compromised structural integrity, potentially leading to driveshaft misalignment or failure. Regular inspection of trunnion bearings and seals helps detect early signs of deterioration, ensuring drivetrain reliability and safety.

Replacement Procedures for Driveshaft Trunnion Assemblies

Replacement procedures for driveshaft trunnion assemblies involve safely supporting the vehicle and disconnecting the driveshaft from the transmission and differential. Carefully remove the worn trunnion by unbolting it from the yoke, ensuring no damage to the splines or surrounding components. Properly lubricate and install the new trunnion assembly, torque all fasteners to manufacturer specifications, and verify alignment to avoid vibrations during operation.

Advantages of High-Quality Trunnions in Automotive Driveshafts

High-quality trunnions in automotive driveshafts enhance rotational stability, reduce vibration, and increase durability under high torque conditions. Precision-engineered trunnions improve power transmission efficiency and minimize wear, leading to longer drivetrain lifespan and lower maintenance costs. Superior materials and tight manufacturing tolerances ensure optimal performance, contributing to better vehicle handling and fuel economy.

example of trunnion in driveshaft Infographic

samplerz.com

samplerz.com