A clamshell hood in automotive design refers to a hood style that wraps over the front fenders, creating a seamless and integrated appearance. This design enhances aerodynamics and improves accessibility to the engine bay for maintenance. The clamshell hood is commonly found in luxury and performance vehicles, showcasing precise engineering and attention to detail. Manufacturers like Tesla and BMW use clamshell hoods to achieve a sleek exterior while maintaining structural integrity. Data shows that vehicles with clamshell hoods often enjoy better airflow management, contributing to improved fuel efficiency and reduced drag coefficients. The clamshell design also supports easier alignment during production, enhancing assembly speed and overall quality control.

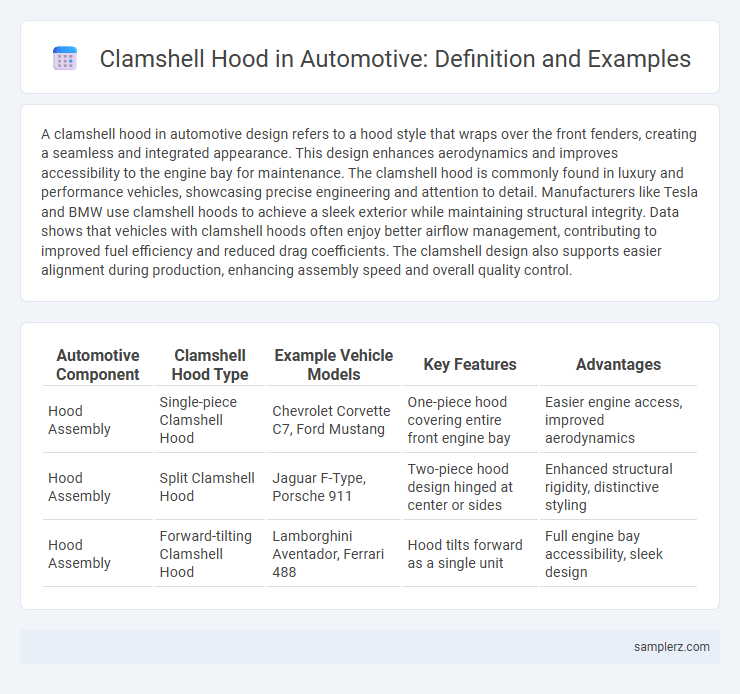

Table of Comparison

| Automotive Component | Clamshell Hood Type | Example Vehicle Models | Key Features | Advantages |

|---|---|---|---|---|

| Hood Assembly | Single-piece Clamshell Hood | Chevrolet Corvette C7, Ford Mustang | One-piece hood covering entire front engine bay | Easier engine access, improved aerodynamics |

| Hood Assembly | Split Clamshell Hood | Jaguar F-Type, Porsche 911 | Two-piece hood design hinged at center or sides | Enhanced structural rigidity, distinctive styling |

| Hood Assembly | Forward-tilting Clamshell Hood | Lamborghini Aventador, Ferrari 488 | Hood tilts forward as a single unit | Full engine bay accessibility, sleek design |

Definition of Clamshell Hood in Automotive Design

A clamshell hood in automotive design refers to a hood configuration where the engine cover wraps around the front fenders to form a single, unified panel. This design enhances aerodynamics by reducing gaps and seams, improving airflow over the vehicle's front end. Commonly found in performance and luxury vehicles, the clamshell hood also facilitates easier access to the engine bay for maintenance and repairs.

Historical Evolution of Clamshell Hoods

Clamshell hoods emerged in the automotive industry during the 1930s as a design innovation that integrated the hood and fenders into a single, hinged unit, enhancing accessibility and styling. Iconic models such as the 1936 Chrysler Airflow and the 1941 Cadillac series showcased early clamshell hood designs, reflecting advances in aerodynamics and manufacturing techniques. This evolution continued through mid-20th century vehicles, influencing modern hood engineering by combining improved structural integrity with streamlined aesthetics.

Iconic Cars Featuring Clamshell Hoods

Iconic cars featuring clamshell hoods include the Jaguar E-Type, known for its seamless front-opening design that enhances engine accessibility and aerodynamic efficiency. The Shelby Cobra also showcases a clamshell hood, combining vintage styling with practical maintenance advantages. These models demonstrate how clamshell hoods improve both aesthetics and functionality in automotive engineering.

Key Design Features of Clamshell Hoods

Clamshell hoods in automotive design feature a single-piece construction that wraps around the front fenders, enhancing structural rigidity and reducing panel gaps for improved aerodynamics. The integrated design allows for easier manufacturing and better alignment with the vehicle's body lines, contributing to both aesthetic appeal and functional performance. Key design elements include seamless edges, reinforced hinge points, and strategically placed vents for optimal heat dissipation under the hood.

Advantages of Clamshell Hood Mechanisms

Clamshell hood mechanisms in automotive design offer enhanced aerodynamics by allowing seamless integration with the vehicle's front fascia, reducing drag and improving fuel efficiency. Their large, single-panel design enables easier engine access for maintenance and repairs, increasing service convenience. Furthermore, clamshell hoods contribute to improved crash safety by providing controlled deformation zones that help absorb impact energy.

Drawbacks and Limitations of Clamshell Hoods

Clamshell hoods in automotive design often present challenges such as increased manufacturing complexity and higher production costs due to their large, integrated panels. Their substantial size can lead to difficulties in accessing engine components for maintenance, reducing serviceability and repair convenience. Weight considerations also impact vehicle performance and fuel efficiency, limiting their application in lightweight or high-performance vehicles.

Manufacturing Process of Clamshell Automotive Hoods

The manufacturing process of clamshell automotive hoods involves stamping and forming two separate panels that join seamlessly to create a single, cohesive surface for improved aerodynamics and aesthetics. Advanced robotics and precision welding techniques ensure high structural integrity and tight dimensional tolerances during assembly. Quality control measures such as laser scanning and ultrasonic testing verify panel alignment and detect defects, optimizing durability and performance.

Maintenance Tips for Clamshell Hood Vehicles

Clamshell hoods, commonly found in modern SUVs and trucks, provide easy access to engine compartments, enhancing maintenance efficiency. Regular lubrication of hinges and checking gas struts for proper pressure prevent hood sagging and ensure smooth operation. Inspecting seals for cracks or wear protects the engine bay from debris and moisture, maintaining optimal vehicle performance.

Modern Vehicles with Clamshell Hood Examples

Modern vehicles with clamshell hoods, such as the Tesla Model S and the Audi A8, showcase sleek design and enhanced aerodynamics by integrating the hood and front fenders into a single, seamless panel. This design simplifies manufacturing, improves access to the engine bay for maintenance, and reduces gaps that can cause wind noise. Clamshell hoods contribute to modern automotive aesthetics while offering functional benefits in terms of repair cost and vehicle performance.

Future Trends in Clamshell Hood Applications

Future trends in clamshell hood applications highlight the integration of lightweight composite materials to enhance fuel efficiency and reduce emissions. Advanced manufacturing technologies such as additive manufacturing enable complex aerodynamic designs that improve vehicle performance and cooling efficiency. Growth in electric vehicle adoption drives clamshell hoods to accommodate larger battery packs and thermal management systems while maintaining structural rigidity.

example of clamshell in hood Infographic

samplerz.com

samplerz.com