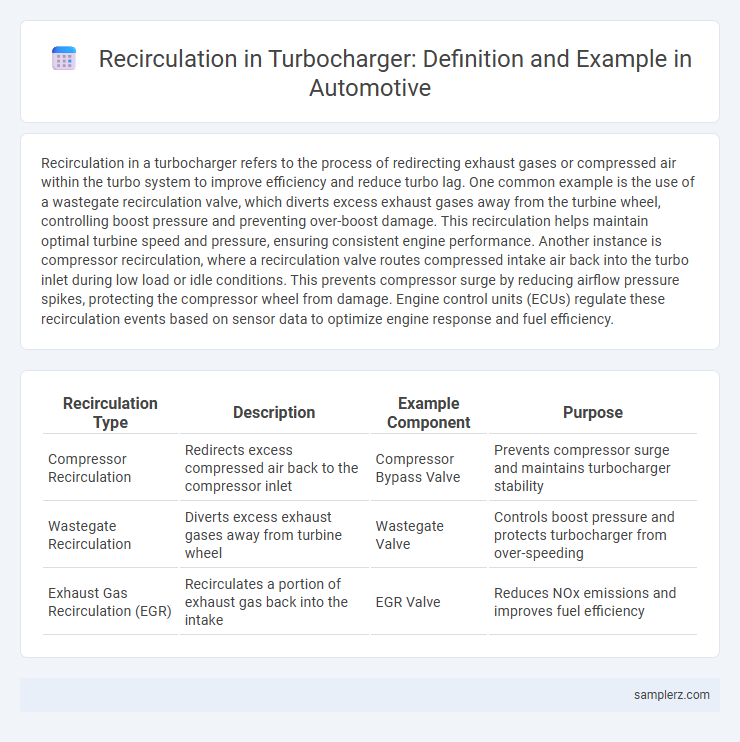

Recirculation in a turbocharger refers to the process of redirecting exhaust gases or compressed air within the turbo system to improve efficiency and reduce turbo lag. One common example is the use of a wastegate recirculation valve, which diverts excess exhaust gases away from the turbine wheel, controlling boost pressure and preventing over-boost damage. This recirculation helps maintain optimal turbine speed and pressure, ensuring consistent engine performance. Another instance is compressor recirculation, where a recirculation valve routes compressed intake air back into the turbo inlet during low load or idle conditions. This prevents compressor surge by reducing airflow pressure spikes, protecting the compressor wheel from damage. Engine control units (ECUs) regulate these recirculation events based on sensor data to optimize engine response and fuel efficiency.

Table of Comparison

| Recirculation Type | Description | Example Component | Purpose |

|---|---|---|---|

| Compressor Recirculation | Redirects excess compressed air back to the compressor inlet | Compressor Bypass Valve | Prevents compressor surge and maintains turbocharger stability |

| Wastegate Recirculation | Diverts excess exhaust gases away from turbine wheel | Wastegate Valve | Controls boost pressure and protects turbocharger from over-speeding |

| Exhaust Gas Recirculation (EGR) | Recirculates a portion of exhaust gas back into the intake | EGR Valve | Reduces NOx emissions and improves fuel efficiency |

Understanding Recirculation in Turbochargers

Recirculation in turbochargers involves redirecting excess exhaust gases back into the turbocharger system to maintain optimal boost pressure and reduce turbo lag. This process enhances engine efficiency by stabilizing the turbine speed during sudden throttle changes, improving overall performance and fuel economy. Effective recirculation techniques, such as blow-off valves and bypass systems, are crucial in modern turbocharged engines to manage pressure fluctuations and prevent compressor surge.

Key Components Involved in Turbo Recirculation

Turbocharger recirculation relies on key components such as the wastegate, which controls exhaust gas flow to manage boost pressure effectively. The blow-off valve prevents compressor surge by releasing excess pressure from the intake system back into the atmosphere or intake path. Additionally, the recirculation valve enables smooth airflow by redirecting excess boost pressure, enhancing turbocharger efficiency and preventing compressor stall.

How Recirculation Improves Turbo Efficiency

Recirculation in turbochargers involves redirecting exhaust gases back into the turbine housing to maintain optimal turbine speed and reduce lag. This process stabilizes boost pressure and enhances the energy extraction from exhaust gases, improving overall turbo efficiency. Improved boost response and reduced turbo lag result in better engine performance and fuel efficiency in automotive applications.

Common Types of Recirculation Systems in Turbos

Common types of recirculation systems in turbochargers include the wastegate recirculation system, which controls exhaust gas flow to regulate boost pressure, and the blow-off valve (BOV) recirculation system that manages excess boost by redirecting excess pressure back into the intake. Another prevalent system is the bypass valve recirculation, designed to prevent compressor surge by allowing air to recirculate when throttle closure is abrupt. These systems enhance turbo efficiency, reduce turbo lag, and protect the turbocharger from damage.

Example: Recirculation Valve Operation Explained

The recirculation valve in a turbocharger controls excess boost pressure by redirecting compressed air back to the compressor inlet, preventing compressor surge and maintaining engine efficiency. During rapid throttle closures, the valve opens to release pressurized air, protecting turbocharger components and ensuring smooth acceleration response. This precise regulation enhances turbo longevity and optimizes performance in modern automotive engines.

Impact of Recirculation on Turbo Lag Reduction

Recirculation valves in turbochargers redirect excess exhaust gases back into the turbine housing, maintaining turbine speed and minimizing pressure spikes. This process significantly reduces turbo lag by ensuring continuous spool-up during throttle changes, enhancing engine responsiveness. Optimized recirculation mechanisms improve overall turbo efficiency and driving performance, particularly in high-boost applications.

Recirculation in Aftermarket Turbo Upgrades

Recirculation in aftermarket turbo upgrades enhances boost control by preventing compressor surge and improving throttle response, especially in high-performance applications. By incorporating a recirculation valve, excess boost pressure is redirected back to the turbo inlet, reducing turbo lag and maintaining system stability. This modification optimizes airflow dynamics, resulting in improved engine efficiency and prolonged turbocharger lifespan.

Symptoms of Recirculation System Failure

Symptoms of recirculation system failure in a turbocharger include excessive turbo lag, reduced engine power, and abnormal boost pressure fluctuations. Drivers may notice a whistling or hissing noise due to a malfunctioning recirculation valve, alongside increased exhaust emissions and potential engine warning lights. In severe cases, persistent boost leaks can lead to poor fuel efficiency and engine stalling.

Comparative Analysis: Recirculation vs Blow-Off Valve

Recirculation valves in turbochargers redirect excess boost pressure back into the intake system, reducing compressor surge and maintaining turbocharger efficiency under throttle lift conditions. Compared to blow-off valves, which release excess pressure to the atmosphere to prevent compressor stall, recirculation valves minimize noise and maintain optimal air-fuel mixture for improved engine performance and reduced emissions. This controlled recirculation enhances throttle responsiveness and prolongs turbocharger lifespan by preventing abrupt pressure fluctuations.

Best Practices for Maintaining Recirculation Systems

Maintaining recirculation systems in turbochargers involves regularly inspecting the wastegate and blow-off valves to ensure proper functioning and prevent boost leaks. Using high-quality lubricants and replacing worn seals helps maintain system integrity and performance. Implementing scheduled cleaning protocols for the recirculation valves prevents carbon buildup, enhancing overall turbocharger efficiency and longevity.

example of recirculation in turbocharger Infographic

samplerz.com

samplerz.com