The steering knuckle is a crucial component in automotive suspension and steering systems. It connects the wheel hub to the suspension components, allowing the wheels to pivot when the driver turns the steering wheel. The knuckle typically houses the wheel bearing and provides attachment points for the brake caliper and tie rod end. In a typical front-wheel-drive vehicle, the steering knuckle links the control arms and the steering linkage. It ensures precise wheel alignment and stable handling by transmitting steering input from the tie rod to the wheel assembly. High-strength materials like forged steel or aluminum are often used to manufacture steering knuckles to withstand stress and impact.

Table of Comparison

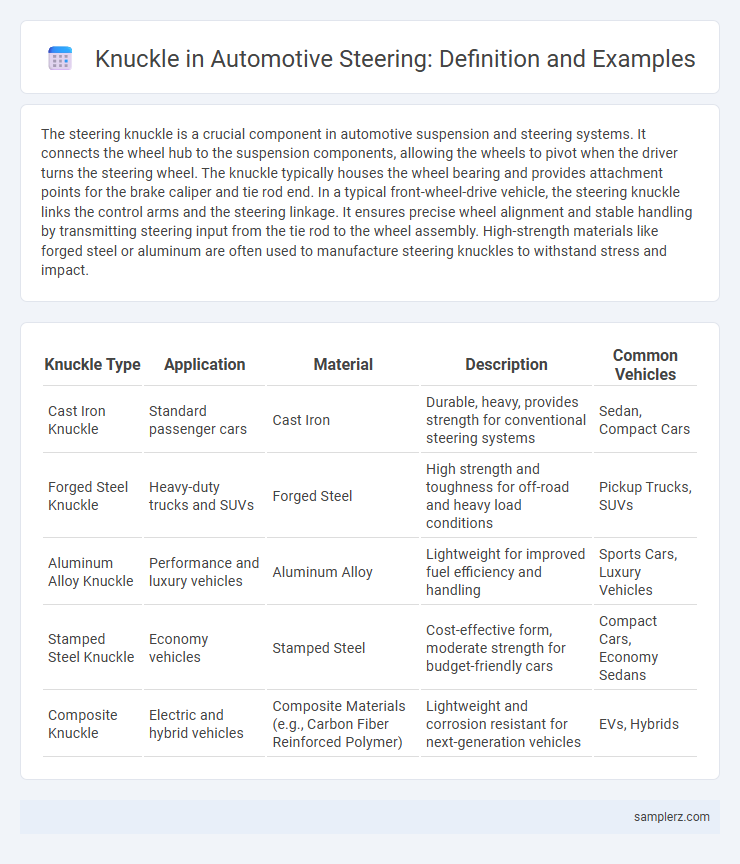

| Knuckle Type | Application | Material | Description | Common Vehicles |

|---|---|---|---|---|

| Cast Iron Knuckle | Standard passenger cars | Cast Iron | Durable, heavy, provides strength for conventional steering systems | Sedan, Compact Cars |

| Forged Steel Knuckle | Heavy-duty trucks and SUVs | Forged Steel | High strength and toughness for off-road and heavy load conditions | Pickup Trucks, SUVs |

| Aluminum Alloy Knuckle | Performance and luxury vehicles | Aluminum Alloy | Lightweight for improved fuel efficiency and handling | Sports Cars, Luxury Vehicles |

| Stamped Steel Knuckle | Economy vehicles | Stamped Steel | Cost-effective form, moderate strength for budget-friendly cars | Compact Cars, Economy Sedans |

| Composite Knuckle | Electric and hybrid vehicles | Composite Materials (e.g., Carbon Fiber Reinforced Polymer) | Lightweight and corrosion resistant for next-generation vehicles | EVs, Hybrids |

Introduction to Steering Knuckle in Automotive Systems

The steering knuckle is a critical component in automotive suspension and steering systems, serving as the pivot point that connects the wheel hub to the suspension components. It facilitates smooth turning by transmitting steering input from the tie rods to the wheels while supporting the vehicle's weight. Modern steering knuckles are engineered with high-strength materials like forged steel or aluminum alloys to balance durability, weight reduction, and performance.

Role of the Knuckle in Vehicle Steering Mechanisms

The steering knuckle serves as the critical connecting component between the wheel hub and suspension, facilitating precise wheel turning by transferring steering inputs from the tie rods to the wheels. It supports key components such as the wheel bearings, brake calipers, and spindle, ensuring proper alignment and stability during maneuvering. By enabling smooth pivoting and load distribution, the knuckle plays a vital role in maintaining vehicle control and handling responsiveness.

Types of Steering Knuckles Used in Vehicles

Steering knuckles in vehicles vary primarily between I-beam, C-clip, and ball joint types, each designed to optimize performance and durability. I-beam knuckles are common in heavy-duty trucks due to their strength, while C-clip knuckles offer ease of maintenance and are often found in older or classic cars. Ball joint knuckles provide enhanced flexibility and are widely used in modern passenger vehicles to improve steering precision and ride comfort.

Key Components Connected to the Steering Knuckle

Key components connected to the steering knuckle include the wheel hub, control arms, and the tie rod end, which collectively facilitate precise wheel movement and steering control. The wheel hub is mounted directly to the knuckle, supporting the wheel bearing and brake assembly, while control arms attach to the knuckle via ball joints, enabling up-and-down suspension travel. The tie rod end links to the knuckle, transmitting steering input from the steering rack to turn the wheels effectively.

Front Steering Knuckle vs. Rear Knuckle: Differences

Front steering knuckles are engineered to connect the suspension and steering components, allowing directional control and bearing dynamic loads during cornering, while rear knuckles primarily anchor the rear suspension and support wheel rotation without steering functionality. The front knuckle integrates ball joints, tie rod ends, and spindle hubs for precise steering response, contrasting with rear knuckles which focus on stability and load distribution. Materials and design of front knuckles emphasize lightweight strength for handling forces, whereas rear knuckles prioritize durability and strength for traction and braking performance.

Common Materials Used for Steering Knuckles

Steering knuckles in automotive applications are commonly made from forged steel, cast iron, and aluminum alloys due to their strength, durability, and weight-saving properties. Forged steel offers high tensile strength and impact resistance, making it ideal for heavy-duty vehicles. Aluminum alloys provide a lightweight alternative that enhances fuel efficiency without compromising structural integrity.

Real-World Examples of Steering Knuckle Applications

Steering knuckles are crucial components in automotive suspension systems, directly linking the wheels to the steering and suspension. In real-world applications, vehicles such as the Toyota Camry and Ford F-150 utilize steering knuckles made from forged steel or aluminum to enhance durability and reduce weight. These knuckles facilitate precise wheel alignment and smooth steering response, improving overall vehicle handling and safety.

Signs of Steering Knuckle Wear or Failure

Steering knuckle wear or failure often manifests through symptoms such as uneven tire wear, excessive play in the steering wheel, and noticeable clunking noises during turns. Drivers may also experience vibrations or pulling to one side while driving, indicating compromised knuckle integrity affecting wheel alignment and suspension performance. Early detection of these signs is critical to prevent more severe steering system damage and ensure vehicle safety.

Maintenance and Inspection Tips for Steering Knuckles

Regular inspection of the steering knuckle involves checking for cracks, corrosion, and wear that can compromise steering precision and safety. Use a dial indicator to measure runout and ensure no deformation has occurred, while also verifying the tightness of ball joint and bearing connections. Timely lubrication of knuckle bearings and prompt replacement of damaged components prevent premature steering system failures and enhance vehicle handling performance.

Innovative Designs and Trends in Steering Knuckle Technology

Innovative steering knuckle designs incorporate lightweight materials such as forged aluminum and advanced composites, significantly reducing unsprung mass and enhancing vehicle handling. Integration of sensor technology within the knuckle supports adaptive steering systems, enabling real-time adjustments for improved stability and safety. Emerging trends also highlight modular knuckle architectures that facilitate easier assembly and maintenance while allowing compatibility with electric power steering and autonomous driving technologies.

example of knuckle in steering Infographic

samplerz.com

samplerz.com