A coffin bushing in a control arm refers to a specific type of suspension bushing designed to reduce vibrations and provide a pivot point between the control arm and the vehicle frame. Typically made from rubber or polyurethane, the coffin bushing absorbs road shocks and helps maintain alignment by allowing controlled movement. Its unique shape resembles a coffin, which helps distribute stress evenly and improves suspension durability. Control arms equipped with coffin bushings are essential components in automotive suspension systems, ensuring better handling and ride comfort. Data from vehicle dynamics studies show that these bushings contribute to decreased noise, vibration, and harshness (NVH) levels. Manufacturers often integrate coffin bushings in front and rear suspension control arms to enhance overall driving stability and extend the lifespan of suspension components.

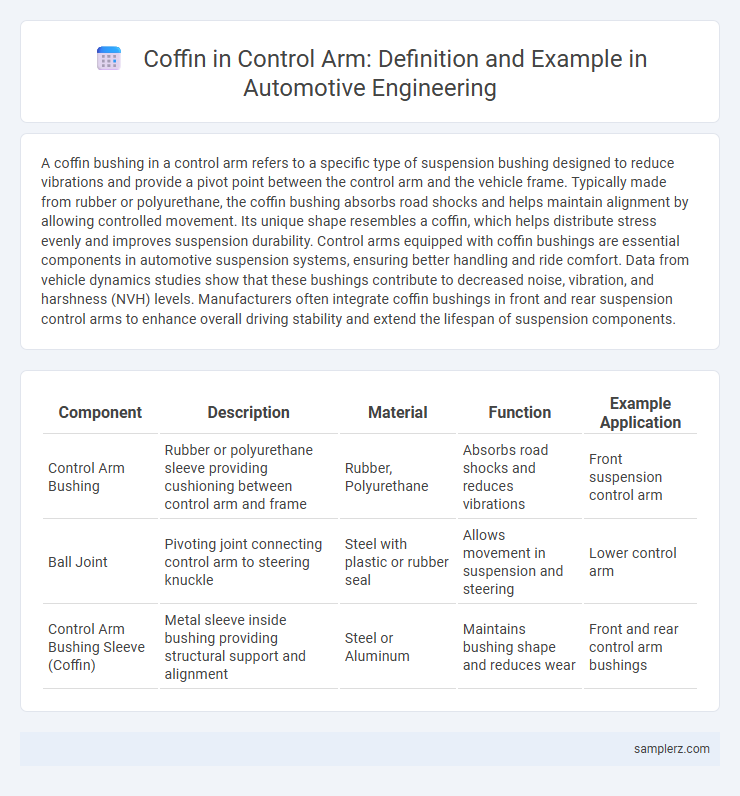

Table of Comparison

| Component | Description | Material | Function | Example Application |

|---|---|---|---|---|

| Control Arm Bushing | Rubber or polyurethane sleeve providing cushioning between control arm and frame | Rubber, Polyurethane | Absorbs road shocks and reduces vibrations | Front suspension control arm |

| Ball Joint | Pivoting joint connecting control arm to steering knuckle | Steel with plastic or rubber seal | Allows movement in suspension and steering | Lower control arm |

| Control Arm Bushing Sleeve (Coffin) | Metal sleeve inside bushing providing structural support and alignment | Steel or Aluminum | Maintains bushing shape and reduces wear | Front and rear control arm bushings |

Understanding "Coffin" Design in Control Arms

The "coffin" design in control arms refers to a specific structural shape that enhances rigidity and durability while minimizing weight in automotive suspension systems. This design features hollow, box-like sections resembling a coffin shape, which optimizes stress distribution and improves shock absorption during vehicle operation. Understanding the coffin design helps engineers develop control arms that provide better handling performance and increased lifespan under dynamic driving conditions.

Key Features of Coffin-Shaped Control Arms

Coffin-shaped control arms feature a unique elongated and tapered design that enhances suspension geometry and improves wheel alignment stability. Made from high-strength steel or aluminum alloys, these control arms provide superior durability and resistance to bending under dynamic loads. Their optimized aerodynamic shape reduces drag, contributing to better overall vehicle handling and fuel efficiency.

Applications of Coffin Control Arms in Modern Vehicles

Coffin control arms are extensively used in the suspension systems of modern vehicles, providing enhanced stability and precise wheel alignment. These components are crucial in off-road and performance vehicles, where improved articulation and durability are required under varying road conditions. The application of coffin control arms contributes to optimized handling, reduced tire wear, and increased ride comfort, making them essential for advanced automotive suspension designs.

Advantages of Coffin-Shaped Control Arm Geometry

Coffin-shaped control arm geometry enhances suspension performance by providing increased structural rigidity and improved load distribution, which reduces stress concentrations and extends component lifespan. This design allows for better alignment control and suspension travel, resulting in improved handling and ride comfort. Its optimized shape also contributes to weight reduction, enhancing overall vehicle efficiency and responsiveness.

Popular Car Models Utilizing Coffin Control Arms

Popular car models utilizing coffin control arms include the Toyota Camry, Honda Accord, and Ford Fusion, known for their enhanced suspension stability and ride comfort. These vehicles benefit from the coffin control arm's unique design, which reduces torque steer and provides precise wheel alignment. Automotive engineers favor coffin control arms in mid-size sedans for improved durability and handling performance.

Comparing Coffin Control Arms vs. Traditional Designs

Coffin control arms feature a distinctive tubular, box-like structure that enhances rigidity and reduces weight compared to traditional stamped steel control arms, leading to improved suspension precision and vehicle handling. The advanced geometry of coffin designs minimizes flex under load, contributing to superior alignment stability and extended component lifespan. In contrast, traditional designs often sacrifice durability for simplicity and are more prone to deformation, which can negatively affect ride quality and maintenance costs over time.

Materials Commonly Used for Coffin Control Arms

Coffin control arms in automotive suspension systems are typically made from high-strength steel alloys and aluminum due to their excellent combination of durability, lightweight properties, and resistance to corrosion. Steel variants often incorporate treated carbon or alloy steels to enhance fatigue resistance, while aluminum versions employ advanced casting or forging techniques for improved rigidity and reduced unsprung weight. Composite materials and reinforced polymers are emerging alternatives, offering enhanced flexibility and vibration damping in modern vehicle designs.

Signs of Wear in Coffin-Style Control Arms

Signs of wear in coffin-style control arms often include uneven tire wear, clunking noises during suspension movement, and visible cracks or deterioration in the rubber bushings. Reduced vehicle stability and increased vibration while driving can also indicate compromised control arm integrity. Regular inspection for corrosion, bushing deformation, and joint looseness is crucial to maintain optimal steering and suspension performance.

Upgrading to Coffin Control Arms: Benefits and Considerations

Upgrading to coffin control arms enhances vehicle suspension by improving durability and reducing unwanted flex during aggressive driving or off-road conditions. These control arms offer precise alignment retention, which contributes to better handling, tire wear, and overall suspension performance. When considering this upgrade, it is essential to evaluate compatibility with existing suspension components and weigh the improved performance benefits against installation complexity and cost.

Maintenance Tips for Coffin-Shaped Control Arms

Coffin-shaped control arms, known for their durability and unique design, require regular inspection for cracks and wear at mounting points to maintain optimal vehicle handling and safety. Lubricating the ball joints and bushings during routine maintenance can prevent premature wear and reduce noise or vibration issues. Always use manufacturer-recommended grease and replace any damaged components promptly to ensure a smooth and safe driving experience.

example of coffin in control arm Infographic

samplerz.com

samplerz.com