Jounce in automotive suspension refers to the upward movement of the vehicle's wheel or suspension component when it encounters a bump or uneven surface. This motion compresses the suspension system, including springs and shock absorbers, to absorb impact and maintain tire contact with the road. Measuring jounce displacement helps engineers evaluate suspension performance and ride comfort. Typical examples of jounce occur when a car drives over a speed bump or pothole. The wheel moves upward relative to the vehicle body, causing the springs to compress and dampers to engage. Accurate jounce data enables optimization of suspension tuning for enhanced stability, handling, and passenger safety.

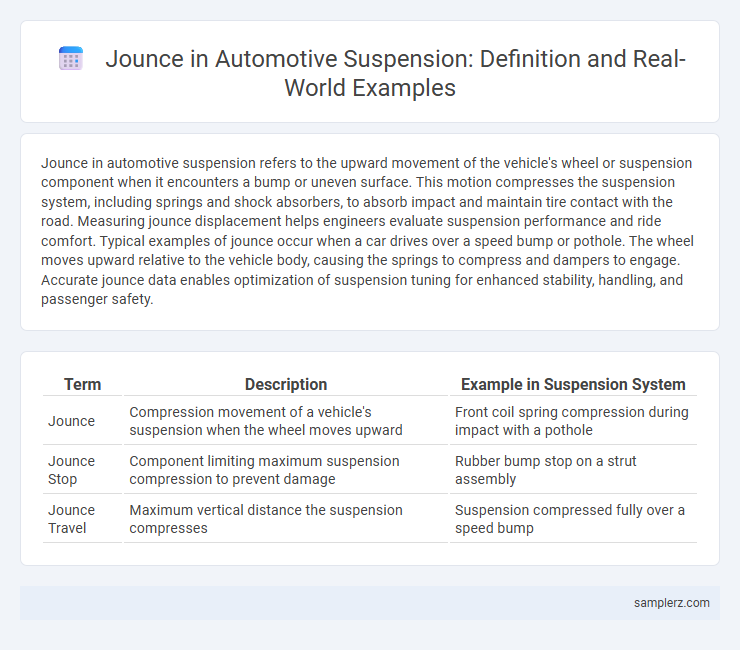

Table of Comparison

| Term | Description | Example in Suspension System |

|---|---|---|

| Jounce | Compression movement of a vehicle's suspension when the wheel moves upward | Front coil spring compression during impact with a pothole |

| Jounce Stop | Component limiting maximum suspension compression to prevent damage | Rubber bump stop on a strut assembly |

| Jounce Travel | Maximum vertical distance the suspension compresses | Suspension compressed fully over a speed bump |

Understanding Jounce in Automotive Suspension Systems

Jounce in automotive suspension refers to the upward compression of the suspension system when a vehicle encounters an obstacle or bump. It plays a critical role in maintaining tire contact with the road, enhancing vehicle stability and ride comfort. Properly designed jounce travel in suspension components such as struts and coil springs ensures effective shock absorption and improves overall handling performance.

Key Functions of Jounce in Vehicle Stability

Jounce in automotive suspension refers to the upward movement of the wheel and suspension components during compression, playing a crucial role in absorbing road shocks and maintaining tire contact with the road surface. This function directly impacts vehicle stability by minimizing body roll and enhancing ride comfort, especially during cornering or over uneven terrain. Effective jounce control improves traction and handling, contributing to overall safety and performance in various driving conditions.

Common Scenarios Where Jounce Occurs

Jounce in automotive suspension typically occurs during aggressive braking, driving over large potholes, or sudden impacts with speed bumps, causing the suspension to compress rapidly. This compression helps absorb shocks and maintain vehicle stability by preventing excessive tire detachment from the road surface. Common vehicle components affected by jounce include coil springs, shock absorbers, and control arms, which work together to manage dynamic load changes and improve ride comfort.

Real-World Examples of Jounce During Driving

Jounce in automotive suspension occurs when a vehicle's wheels encounter bumps or potholes, causing the suspension to compress sharply. For example, hitting a speed bump at moderate speed causes noticeable suspension jounce, absorbing energy to maintain tire contact with the road. Off-road driving on uneven terrain intensifies jounce cycles, highlighting suspension components like shocks and struts designed to handle rapid compression and rebound.

Jounce vs. Rebound: Key Suspension Movements

Jounce refers to the upward movement of a vehicle's suspension as the wheel compresses when it hits a bump, while rebound describes the suspension extending after compression. Effective suspension systems balance jounce and rebound to maintain tire contact and ride comfort, optimizing handling and stability. The interplay between these movements is crucial for absorbing road irregularities and minimizing chassis oscillations.

How Jounce Influences Ride Comfort

Jounce, the upward movement of a vehicle's suspension, directly impacts ride comfort by absorbing shocks from road irregularities and preventing harsh impacts from reaching the cabin. Suspension systems with well-tuned jounce control optimize the absorption of vertical wheel travel, reducing vibrations and enhancing passenger comfort. Precise jounce management in components like shock absorbers and springs ensures smoother rides by limiting excessive suspension compression during sudden bumps or potholes.

Impact of Jounce on Suspension Components

Jounce in automotive suspension refers to the upward travel of the wheel and suspension components when encountering a bump or obstacle. Excessive jounce can cause accelerated wear on shock absorbers, springs, and bushings, leading to reduced ride comfort and compromised handling stability. Properly tuned suspension systems minimize jounce impact, enhancing component longevity and vehicle performance.

Signs of Excessive Jounce in Your Vehicle

Excessive jounce in your vehicle's suspension often causes noticeable symptoms such as harsh impacts when driving over bumps, increased noise from the struts or shocks, and a rough ride quality. You may also observe uneven tire wear and reduced handling stability, indicating the suspension components are compressing beyond their designed limits. Addressing these signs promptly helps prevent further damage to suspension parts and maintains vehicle safety.

Engineering Solutions to Manage Jounce

Advanced engineering solutions to manage jounce in automotive suspension systems include the integration of progressive-rate springs and hydraulic bump stops designed to absorb and dissipate impact forces during wheel travel compression. Utilizing computer-aided simulations allows precise calibration of suspension components to optimize ride comfort and handling stability by controlling chassis movement within jounce limits. Incorporating adaptive damping technologies further refines energy absorption, reducing harshness and enhancing overall vehicle dynamics under various road conditions.

Jounce Testing Procedures in Automotive Engineering

Jounce testing procedures in automotive engineering evaluate suspension performance by simulating extreme compression of the suspension system to identify potential failure points and ensure durability. Engineers use specialized jounce machines to measure forces and displacement under controlled loading conditions, replicating real-world harsh impacts such as potholes or bumps. Data obtained from jounce tests guide the optimization of spring rates, damper settings, and suspension geometry to enhance vehicle ride quality and safety.

example of jounce in suspension Infographic

samplerz.com

samplerz.com