Stiction in a shock absorber refers to the initial resistance to movement caused by friction between the shock's internal components, such as the piston and the cylinder. This phenomenon occurs when the shock absorber remains stationary for a period, causing the lubrication film to thin and increase contact friction. High stiction can lead to a harsh ride quality and reduced suspension responsiveness, negatively impacting vehicle handling and comfort. In automotive applications, stiction is often observed when a vehicle starts moving after being parked, causing the shock absorber to resist initial compression or rebound. Typical data points indicating stiction include elevated force thresholds required to initiate shock movement and increased damping irregularities at slow velocities. Manufacturers seek to minimize stiction using advanced coatings, improved seals, and optimized lubricant formulations to ensure consistent shock performance and enhanced ride smoothness.

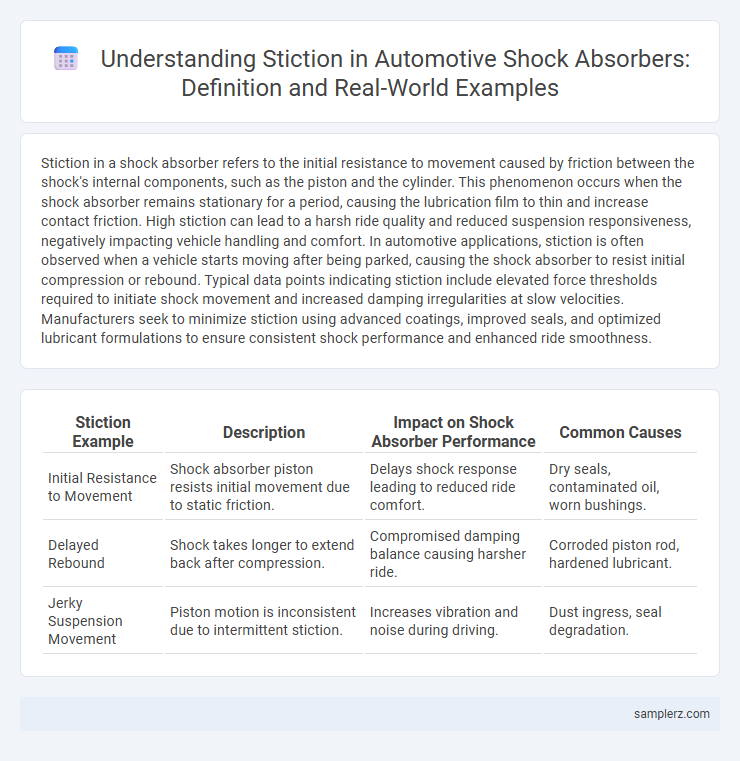

Table of Comparison

| Stiction Example | Description | Impact on Shock Absorber Performance | Common Causes |

|---|---|---|---|

| Initial Resistance to Movement | Shock absorber piston resists initial movement due to static friction. | Delays shock response leading to reduced ride comfort. | Dry seals, contaminated oil, worn bushings. |

| Delayed Rebound | Shock takes longer to extend back after compression. | Compromised damping balance causing harsher ride. | Corroded piston rod, hardened lubricant. |

| Jerky Suspension Movement | Piston motion is inconsistent due to intermittent stiction. | Increases vibration and noise during driving. | Dust ingress, seal degradation. |

What Is Stiction in Shock Absorbers?

Stiction in shock absorbers refers to the static friction that occurs when the shock's piston is at rest, preventing smooth initial movement and causing hesitation or jerky motion. This phenomenon typically results from worn or damaged seals, contaminated oil, or corrosion within the shock absorber's cylinder. Excessive stiction leads to reduced damping efficiency, impairing vehicle handling and ride comfort.

Common Causes of Stiction in Automotive Shocks

Stiction in automotive shock absorbers commonly results from the accumulation of dirt, corrosion on the piston rod, and deterioration of internal seals that hinder smooth movement. Oil contamination or thickened damping fluid increases friction between the moving parts, creating resistance during suspension travel. Temperature fluctuations causing fluid viscosity changes also contribute significantly to the onset of stiction in shocks.

Stiction vs. Friction: Key Differences in Shock Absorbers

Stiction in shock absorbers refers to the initial resistance encountered when the damper starts to move, caused by microscopic adhesion between the piston and the cylinder surfaces. Unlike general friction, which involves continuous resistance during motion, stiction is a static force that must be overcome to initiate shock absorber movement, impacting ride comfort and suspension responsiveness. Understanding the distinction between stiction and friction is crucial for optimizing shock absorber performance and enhancing vehicle handling dynamics.

Real-World Examples of Stiction in Shocks

Stiction in shock absorbers commonly occurs in older vehicles with worn seals or contaminated damping fluids, leading to uneven suspension response and reduced ride comfort. For instance, a Jeep Wrangler with high-mileage off-road use often exhibits stiction due to dirt infiltration causing piston rod sticking, impairing shock damping performance. In real-world tests, passenger cars like the Toyota Camry demonstrate stiction effects during low-speed maneuvers, where friction prevents smooth shock absorber compression and rebound, resulting in a harsh and unpredictable driving experience.

Symptoms of Stiction in Vehicle Suspension

Stiction in shock absorbers causes uneven damping response, resulting in a harsh or bouncy ride and reduced control over road vibrations. Symptoms include increased noise such as knocking or clunking sounds during suspension movement and poor vehicle stability at low speeds or over bumps. Drivers may also notice increased tire wear and a compromised handling performance due to inconsistent shock absorber action.

How Stiction Affects Ride Comfort and Handling

Stiction in shock absorbers occurs when internal friction prevents smooth movement between the piston and cylinder, leading to delayed suspension response. This phenomenon reduces ride comfort by causing a harsh, jerky motion over small bumps and diminishes handling precision as the suspension cannot quickly adapt to road irregularities. Effective damping performance is compromised, resulting in decreased vehicle stability and increased driver fatigue on uneven surfaces.

Diagnosing Stiction in Automotive Shock Absorbers

Stiction in automotive shock absorbers is diagnosed by observing uneven tire wear, excessive body roll, and a noticeable clunking sound during suspension movement. Technicians perform a bounce test to assess damping consistency and use specialized tools like shock dynometers to measure resistance changes caused by stiction. Identifying stiction early helps maintain vehicle stability, ride comfort, and prolongs shock absorber lifespan.

Reducing Stiction in Shocks: Best Practices

Reducing stiction in shock absorbers improves vehicle suspension performance and ride comfort by minimizing friction between the piston and cylinder components. Applying high-quality synthetic lubricants and ensuring precise manufacturing tolerances for seals and bushings are critical best practices for lowering stiction levels. Regular maintenance and the use of advanced low-friction coatings on internal parts further enhance shock absorber responsiveness and longevity.

The Role of Shock Absorber Maintenance in Stiction Prevention

Shock absorber stiction occurs when internal components stick together due to dirt, corrosion, or degraded lubrication, impairing suspension performance and vehicle control. Regular maintenance, including inspection, cleaning, and replacement of worn seals and fluids, ensures smooth piston movement and minimizes friction-related stiction. Preventative upkeep enhances ride comfort, prolongs shock absorber lifespan, and maintains optimal damping efficiency essential for automotive safety.

Stiction Issues in Different Types of Shock Absorbers

Stiction in shock absorbers commonly occurs in twin-tube designs, where oil film adhesion between the piston and cylinder wall impedes initial movement, causing a rough ride and reduced responsiveness. Monotube shock absorbers also experience stiction due to seals and piston rings binding under temperature variations and wear, affecting damping consistency. Gas-charged shocks minimize stiction through pressurized nitrogen that maintains fluid separation, yet improper maintenance or contamination can still lead to resistance issues.

example of stiction in shock absorber Infographic

samplerz.com

samplerz.com