A grommet in an automotive firewall is a rubber or plastic ring designed to protect wires and cables as they pass through the metal firewall panel. It prevents abrasion and damage caused by vibration and friction, ensuring electrical system integrity. These grommets are critical for maintaining the vehicle's safety and preventing moisture or noise intrusion into the passenger compartment. Examples of firewall grommets in automotive applications include engine wiring harness passes, heater control cables, and brake line seals. OEM manufacturers often use custom-sized grommets tailored to fit specific wire bundles or tubing diameters. The grommet material usually exhibits high resistance to heat, oils, and chemicals encountered under the vehicle's hood.

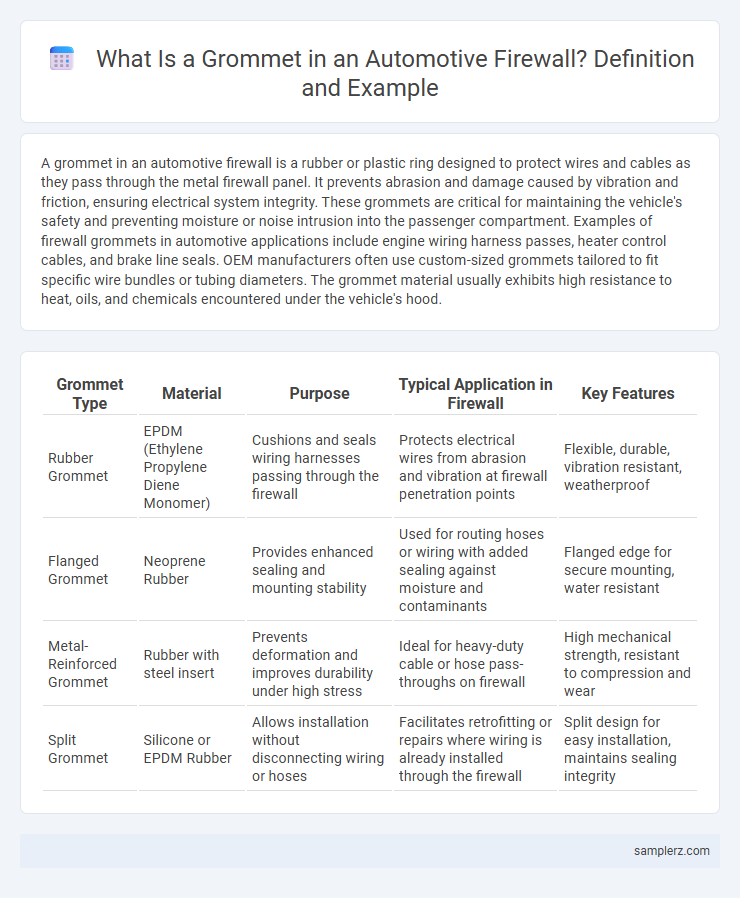

Table of Comparison

| Grommet Type | Material | Purpose | Typical Application in Firewall | Key Features |

|---|---|---|---|---|

| Rubber Grommet | EPDM (Ethylene Propylene Diene Monomer) | Cushions and seals wiring harnesses passing through the firewall | Protects electrical wires from abrasion and vibration at firewall penetration points | Flexible, durable, vibration resistant, weatherproof |

| Flanged Grommet | Neoprene Rubber | Provides enhanced sealing and mounting stability | Used for routing hoses or wiring with added sealing against moisture and contaminants | Flanged edge for secure mounting, water resistant |

| Metal-Reinforced Grommet | Rubber with steel insert | Prevents deformation and improves durability under high stress | Ideal for heavy-duty cable or hose pass-throughs on firewall | High mechanical strength, resistant to compression and wear |

| Split Grommet | Silicone or EPDM Rubber | Allows installation without disconnecting wiring or hoses | Facilitates retrofitting or repairs where wiring is already installed through the firewall | Split design for easy installation, maintains sealing integrity |

Introduction to Firewall Grommets in Vehicles

Firewall grommets in vehicles serve as protective seals where wiring and cables pass through the metal firewall, preventing abrasion and potential damage from vibration. These automotive grommets are typically made from durable rubber or silicone materials engineered to withstand high temperatures and harsh under-hood conditions. Ensuring the integrity of firewall grommets enhances electrical system reliability and safeguards critical vehicle components from moisture and contaminants.

Purpose and Function of Firewall Grommets

Firewall grommets in automotive applications serve as protective seals where wiring harnesses pass through the vehicle's firewall, preventing damage from sharp edges and vibrations. These grommets maintain the integrity of the firewall by sealing gaps to block noise, dust, moisture, and engine heat from entering the passenger compartment. By ensuring secure cable routing, firewall grommets contribute to electrical safety and vehicle durability.

Common Materials Used for Automotive Grommets

Automotive grommets commonly found in firewall applications are made from durable materials such as EPDM rubber, silicone, and neoprene, chosen for their excellent resistance to heat, oil, and chemicals. These materials provide effective sealing, vibration dampening, and protection for wiring harnesses and cables passing through the firewall. EPDM rubber remains the industry standard due to its cost-effectiveness and robust weather resistance, while silicone offers superior thermal stability in high-temperature engine environments.

Typical Locations of Grommets in Car Firewalls

Typical locations of grommets in car firewalls include areas where wiring harnesses, brake lines, and fuel lines pass through the metal firewall, providing protection against abrasion and sealing against water and noise intrusion. These rubber or silicone grommets are often positioned around steering column openings and HVAC duct passages to maintain structural integrity and prevent vibrations. Properly installed grommets enhance the vehicle's overall durability and safety by safeguarding critical systems from damage and environmental exposure.

Wiring Harness Grommets: Protecting Electrical Systems

Wiring harness grommets in automotive firewalls are essential for protecting electrical systems by preventing wires from chafing and short-circuiting as they pass through metal openings. These grommets are made from durable materials such as rubber or silicone, providing a secure seal that blocks moisture, dust, and vibrations, thereby enhancing the longevity of the wiring harness. Proper installation of firewall grommets ensures optimal electrical performance and reduces the risk of system failures in vehicle electrical architectures.

HVAC Line Grommets and Their Importance

HVAC line grommets in automotive firewall applications provide critical sealing and vibration isolation for heating, ventilation, and air conditioning systems. These rubber or silicone grommets prevent moisture, dust, and noise from entering the vehicle cabin while protecting HVAC lines from abrasion and mechanical damage. Proper installation of firewall HVAC line grommets ensures system efficiency and extends the lifespan of HVAC components.

Sealing Fuel Lines with Firewall Grommets

Firewall grommets provide a critical seal for fuel lines passing through the vehicle's firewall, preventing fuel leaks and protecting against engine compartment contaminants. These durable rubber or silicone grommets ensure tight sealing around the fuel lines, maintaining pressure integrity while resisting heat, vibration, and chemical exposure typical in automotive environments. Proper installation of firewall grommets enhances safety by preventing fuel vapor intrusion into the cabin and contributing to overall fire protection standards.

Noise and Vibration Dampening Roles of Grommets

Grommets installed in the firewall of a vehicle play a crucial role in noise and vibration dampening by isolating electrical wires and cables from the rigid metal surfaces, reducing the transmission of vibrations. These rubber or silicone components absorb engine and road noise, preventing it from entering the passenger cabin, thereby enhancing acoustic comfort. Effective firewall grommets contribute to overall vehicle NVH (Noise, Vibration, and Harshness) performance by minimizing rattles and structural-borne noise.

Grommet Installation Tips for Automotive Firewalls

Ensure a snug fit by selecting grommets that match firewall hole diameters precisely to prevent air leaks and protect wiring from abrasion. Use high-quality rubber or silicone grommets resistant to heat and chemicals commonly found in automotive engine compartments. Properly seat the grommet by evenly pressing it into the firewall opening, then carefully route cables or hoses through the center to maintain firewall integrity and enhance durability.

Signs of Worn or Damaged Firewall Grommets

Signs of worn or damaged firewall grommets in automotive applications include visible cracks, tears, or deformation around the grommet material, leading to compromised sealing. Drivers may notice increased noise, water leaks into the cabin, or the presence of engine fumes due to gasket failure. Regular inspection of firewall grommets helps prevent electrical wiring abrasion and maintains proper engine compartment isolation.

example of grommet in firewall Infographic

samplerz.com

samplerz.com