A guibo, also known as a flex disc, is a critical component in automotive drivetrains that connects the driveshaft to the transmission or differential. It is typically made from reinforced rubber and metal, designed to absorb vibrations and reduce noise while allowing slight flexibility in the coupling. The guibo serves as a flexible coupling that compensates for misalignments and protects drivetrain components from shock loads. In coupling applications, the guibo acts as an intermediary element between rigid shaft components, ensuring smooth power transmission. Its unique design incorporates bolt patterns that align with the driveshaft and transmission output flange, securely transmitting torque. The guibo's ability to dampen torsional vibrations enhances the durability of the drivetrain and improves vehicle comfort by minimizing vibration transfer.

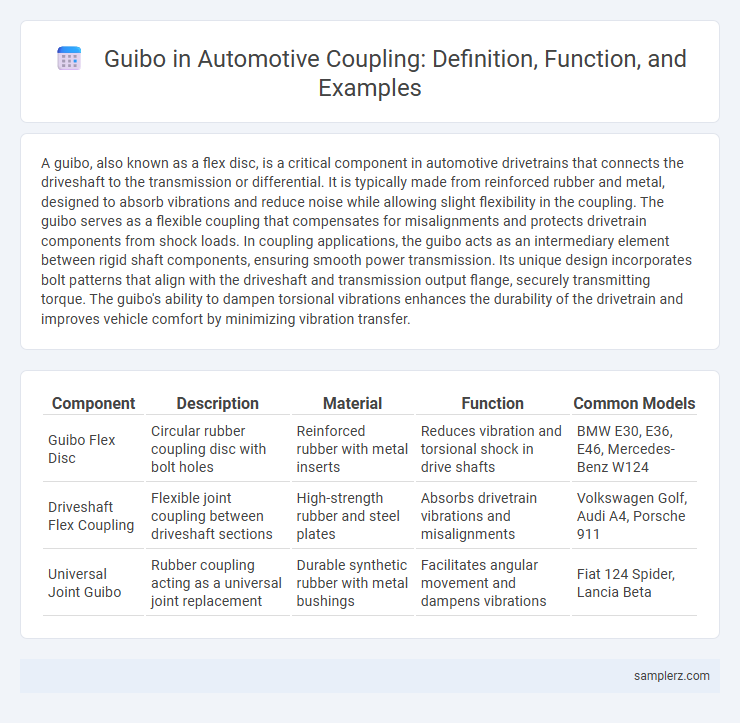

Table of Comparison

| Component | Description | Material | Function | Common Models |

|---|---|---|---|---|

| Guibo Flex Disc | Circular rubber coupling disc with bolt holes | Reinforced rubber with metal inserts | Reduces vibration and torsional shock in drive shafts | BMW E30, E36, E46, Mercedes-Benz W124 |

| Driveshaft Flex Coupling | Flexible joint coupling between driveshaft sections | High-strength rubber and steel plates | Absorbs drivetrain vibrations and misalignments | Volkswagen Golf, Audi A4, Porsche 911 |

| Universal Joint Guibo | Rubber coupling acting as a universal joint replacement | Durable synthetic rubber with metal bushings | Facilitates angular movement and dampens vibrations | Fiat 124 Spider, Lancia Beta |

Understanding the Role of a Guibo in Automotive Coupling

A guibo, also known as a flex disc, is a crucial component in automotive drivetrains that connects the driveshaft to the transmission or differential, absorbing vibrations and reducing mechanical stress. Made from reinforced rubber with embedded metal inserts, the guibo compensates for misalignment and dampens torsional vibrations, enhancing ride comfort and drivetrain longevity. Its flexible design prevents drivetrain damage by distributing torque smoothly, making it essential for maintaining vehicle performance and reliability.

Key Functions of a Guibo in Vehicle Drivetrains

A guibo, also known as a flex disc, serves as a crucial component in automotive drivetrains by connecting the driveshaft to the transmission or differential, effectively reducing vibrations and noise. Its flexible rubber structure absorbs torque fluctuations and mechanical shocks, enhancing drivetrain durability and smoothness during power transmission. By isolating torsional vibrations, the guibo protects the drivetrain components, contributing to improved vehicle performance and driving comfort.

Typical Applications of Guibo Couplings in Cars

Guibo couplings are commonly used in automotive drivetrains to connect the driveshaft to the transmission or differential, providing flexibility and vibration damping. These rubber couplings absorb torque fluctuations and reduce noise, ensuring smoother power transfer in rear-wheel and all-wheel drive vehicles. Typical applications include high-performance sports cars, luxury sedans, and off-road vehicles where drivetrain durability and comfort are critical.

Popular Vehicles Utilizing Guibo Couplings

Popular vehicles utilizing guibo couplings include BMW models such as the 3 Series and 5 Series, which benefit from the flexible driveshaft connection to reduce vibrations. Mercedes-Benz vehicles like the C-Class and E-Class also employ guibo couplings for improved torque transfer and enhanced drivetrain durability. These rubber couplings provide effective damping characteristics essential for smooth power delivery in rear-wheel-drive and all-wheel-drive systems.

Materials Used in Manufacturing Guibo Couplings

Guibo couplings are predominantly manufactured using high-grade rubber compounds combined with fabric reinforcements to provide flexibility and vibration damping in automotive drivetrains. Metal inserts, often steel or aluminum, are embedded within the rubber to enhance strength and ensure secure attachment to the drive shaft and transmission flanges. These materials are selected for their durability, resistance to wear, and ability to withstand environmental factors such as oil exposure and temperature fluctuations.

Symptoms of a Worn or Failing Guibo

A worn or failing guibo often causes noticeable vibrations and clunking noises when accelerating or shifting gears, indicating compromised coupling between the driveshaft and transmission. Drivers may experience increased drivetrain slack or excessive play, resulting in unstable torque transfer and jerky vehicle movement. Visual inspection frequently reveals cracks, tears, or hardened rubber, signaling the need for immediate replacement to avoid drivetrain damage.

Maintenance Tips for Guibo Couplings

Regular inspection of guibo couplings is essential to prevent drivetrain vibrations and premature wear. Check for cracks, tears, and signs of rubber hardening to ensure optimal performance and replace the guibo at the first indication of damage. Proper torque settings on the mounting bolts and periodic lubrication of adjacent components help maintain the coupling's durability and smooth operation.

Comparing Guibo Couplings to Other Flexible Couplers

Guibo couplings, also known as flex discs, excel in automotive drivetrains by providing superior vibration damping and torsional flexibility compared to traditional rubber or jaw-type flexible couplers. Their multi-layered composite construction offers enhanced durability and resistance to wear under high torque conditions, outperforming standard couplings in maintaining drivetrain smoothness and reducing noise. Unlike other flexible couplers, guibo designs enable precise alignment and reduced maintenance needs, making them a preferred choice in performance and luxury vehicles.

Step-by-Step Guide to Replacing a Guibo

Replacing a guibo in a vehicle's drive shaft begins with safely lifting the car and securing it on jack stands to access the coupling. Remove the bolts connecting the guibo to the driveshaft and transmission flange, then carefully detach the worn or cracked guibo, noting its orientation for proper installation. Install the new guibo by aligning it correctly, tightening bolts to the manufacturer's specified torque, and lowering the vehicle to test for smooth driveline operation without vibrations or noises.

Performance Benefits of Guibo-Based Coupling Systems

Guibo-based coupling systems enhance automotive driveline performance by effectively dampening torsional vibrations and reducing noise transmission between the engine and transmission. The flexible rubber material absorbs shocks and torque fluctuations, leading to smoother power delivery and increased component longevity. This results in improved driving comfort, reduced drivetrain wear, and optimized overall vehicle performance.

example of guibo in coupling Infographic

samplerz.com

samplerz.com