A spigot in a crankshaft serves as a precise locating and support feature for the transmission input shaft bearing. Typically, the spigot is a small, cylindrical extension on the crankshaft's front end that fits snugly into the torque converter or clutch assembly. This precise alignment ensures proper engagement and rotational stability between the crankshaft and the transmission system. In automotive engineering, the spigot's dimensions and material composition are critical for maintaining durability under high torque and vibration conditions. Commonly, it is made from hardened steel to resist wear and prevent deformation during engine operation. Accurate machining of the spigot is essential to avoid misalignment, which could lead to premature bearing failure and transmission damage.

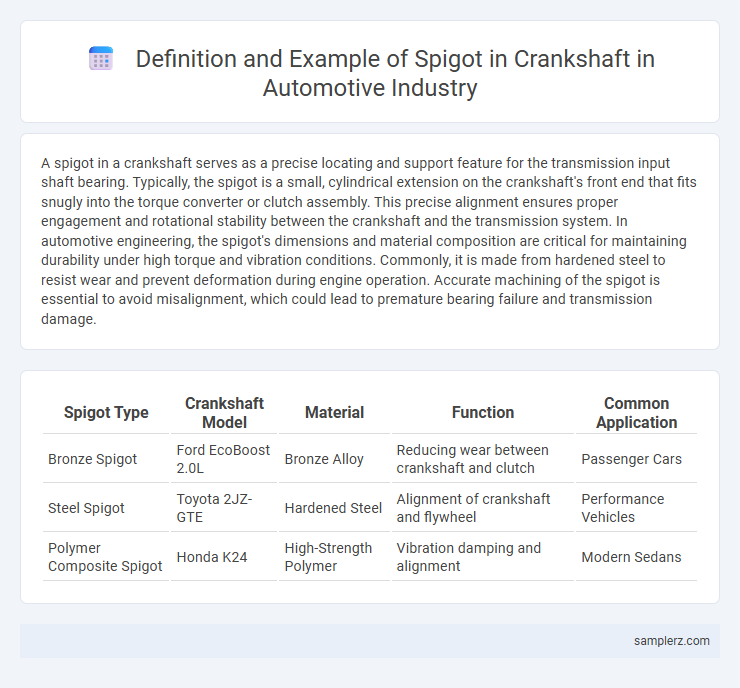

Table of Comparison

| Spigot Type | Crankshaft Model | Material | Function | Common Application |

|---|---|---|---|---|

| Bronze Spigot | Ford EcoBoost 2.0L | Bronze Alloy | Reducing wear between crankshaft and clutch | Passenger Cars |

| Steel Spigot | Toyota 2JZ-GTE | Hardened Steel | Alignment of crankshaft and flywheel | Performance Vehicles |

| Polymer Composite Spigot | Honda K24 | High-Strength Polymer | Vibration damping and alignment | Modern Sedans |

Understanding the Role of the Spigot in Crankshaft Design

The spigot in crankshaft design serves as a precise alignment guide, ensuring the crankshaft and clutch assembly maintain accurate concentricity for optimal engine performance. This cylindrical projection fits into the pilot bearing of the flywheel, reducing vibrations and wear by stabilizing rotational movement. Proper spigot design enhances engine durability and smooth power transmission by maintaining alignment under varying mechanical loads.

Key Functions of a Crankshaft Spigot in Automotive Engines

The crankshaft spigot serves as a precise alignment guide between the crankshaft and the flywheel, ensuring proper rotational balance and smooth engine operation. It provides a secure mounting point that maintains the integrity of torque transfer from the engine to the transmission, minimizing vibration and wear. This component also aids in the accurate positioning of the crankshaft sensor for optimal engine timing and performance monitoring.

Materials Commonly Used for Crankshaft Spigots

Crankshaft spigots are typically made from hardened steel alloys such as 1045 carbon steel or 4340 chromoly steel to ensure durability and resistance to wear under high-stress engine conditions. These materials offer excellent tensile strength and fatigue resistance, critical for maintaining precise alignment in crankshaft assemblies. Surface treatments like nitriding or carburizing are often applied to enhance hardness and extend the service life of crankshaft spigots.

Spigot Placement and Its Impact on Engine Performance

Spigots in crankshafts are precisely positioned to align the transmission input shaft with the engine crankshaft, ensuring smooth power transfer and reducing vibration. Proper spigot placement minimizes wear on the input shaft bearing and maintains optimal crankshaft balance, directly enhancing engine performance and longevity. Misaligned spigots can cause premature bearing failure, increased noise, and diminished engine efficiency.

Typical Applications of Spigots in Crankshaft Assemblies

Spigots in crankshaft assemblies primarily serve as precise alignment features between the crankshaft and other components such as the flywheel or timing gears. Typical applications include ensuring concentricity and rotational stability, which are critical for efficient engine performance and vibration reduction. These spigots enable accurate positioning during assembly, enhancing the durability and reliability of the powertrain system.

Differences Between Crankshaft Spigots in Gasoline vs Diesel Engines

Crankshaft spigots in gasoline engines are typically smaller and designed to accommodate higher RPMs with lighter components, ensuring precise alignment of the crankshaft and flywheel for smoother operation. In contrast, diesel engine spigots are larger and more robust to withstand greater torque and stress, supporting heavier flywheels and enhanced durability under high compression ratios. Material composition also varies, with diesel spigots often using hardened steel alloys to resist wear, while gasoline engine spigots emphasize weight reduction and balanced performance.

Manufacturing Processes for Crankshaft Spigots

Crankshaft spigots are precisely manufactured using CNC machining and grinding processes to achieve tight tolerances and ensure proper fit with connecting components. Heat treatment treatments such as induction hardening improve wear resistance and durability of the spigot surface. Quality control methods like coordinate measuring machines (CMM) verify dimensional accuracy and concentricity essential for optimal engine performance.

Common Issues and Failures in Crankshaft Spigots

Crankshaft spigots often experience wear and deformation due to excessive rotational forces and improper installation, leading to misalignment and vibrations in the engine. Common failures include spigot bore elongation and surface scoring, which compromise the precise fit between the crankshaft and the pilot bearing or gear. Early detection of spigot damage through regular inspection prevents crankshaft imbalance, reduces bearing wear, and ensures optimal engine performance.

Maintenance Tips for Crankshaft Spigots

Regular inspection of the crankshaft spigot ensures proper alignment and prevents premature wear in automotive engines. Applying a light coat of high-quality grease during reassembly helps maintain a secure fit and reduces the risk of corrosion. Using precision tools to check for any deformation or damage supports optimal crankshaft performance and extends engine lifespan.

Innovations and Advances in Spigot Technology for Crankshafts

Recent innovations in spigot technology for crankshafts include the use of advanced composite materials that enhance durability and reduce weight, improving engine efficiency. Precision engineering techniques such as CNC machining and laser hardening have significantly increased the dimensional accuracy and wear resistance of spigots. Integration of smart sensors within spigots enables real-time monitoring of crankshaft alignment and performance, facilitating predictive maintenance and extending engine life.

example of spigot in crankshaft Infographic

samplerz.com

samplerz.com