A Gurney flap is a small aerodynamic device attached to the trailing edge of a car's rear wing or spoiler. This flap, typically a few millimeters high, improves downforce by creating a pressure difference on the wing surfaces. In automotive applications, the Gurney flap enhances cornering stability and grip, essential for high-performance racing vehicles. Modern race cars like those in Formula 1 often use Gurney flaps to optimize aerodynamic efficiency. Data from wind tunnel tests shows that even minor adjustments to the flap height can significantly influence the vehicle's drag and downforce balance. The Gurney flap's effectiveness depends on its precise placement and angle, making it a critical element in race car aerodynamic tuning.

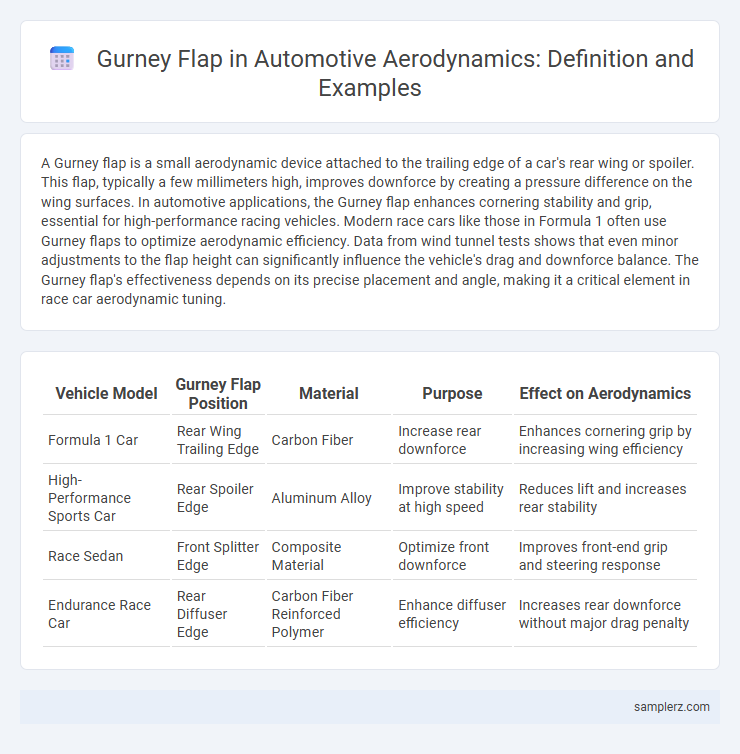

Table of Comparison

| Vehicle Model | Gurney Flap Position | Material | Purpose | Effect on Aerodynamics |

|---|---|---|---|---|

| Formula 1 Car | Rear Wing Trailing Edge | Carbon Fiber | Increase rear downforce | Enhances cornering grip by increasing wing efficiency |

| High-Performance Sports Car | Rear Spoiler Edge | Aluminum Alloy | Improve stability at high speed | Reduces lift and increases rear stability |

| Race Sedan | Front Splitter Edge | Composite Material | Optimize front downforce | Improves front-end grip and steering response |

| Endurance Race Car | Rear Diffuser Edge | Carbon Fiber Reinforced Polymer | Enhance diffuser efficiency | Increases rear downforce without major drag penalty |

Introduction to Gurney Flap in Automotive Aerodynamics

A Gurney flap is a small, perpendicular tab attached to the trailing edge of a car's spoiler or wing, enhancing downforce by altering airflow separation. In automotive aerodynamics, it improves stability and grip without significantly increasing drag, making it popular in racing and high-performance vehicles. The device's simple design delivers measurable gains in cornering speed and overall handling efficiency.

History and Invention of the Gurney Flap

The Gurney flap, invented by American racing driver Dan Gurney in the early 1970s, revolutionized automotive aerodynamics by enhancing downforce without significantly increasing drag. Initially applied to race cars, this small vertical tab on the trailing edge of a wing improved grip and stability at high speeds, helping teams achieve better cornering performance. Its simple yet effective design has since been adopted across various motorsports and high-performance road vehicles to optimize aerodynamic efficiency.

How Gurney Flaps Work: Basic Principles

A Gurney flap operates by creating a small, perpendicular tab on the trailing edge of a car's spoiler, which increases downforce through vortex generation and delayed airflow separation. This aerodynamic tool enhances pressure differences by disrupting airflow, improving grip and stability at high speeds. Its effectiveness stems from modifying lift and drag characteristics without significantly increasing drag, optimizing performance in automotive racing and high-performance vehicles.

Famous Racing Cars Featuring Gurney Flaps

Famous racing cars featuring Gurney flaps include the Porsche 917, which utilized the flap to increase rear downforce without significantly increasing drag, enhancing high-speed stability. The McLaren F1 GTR implemented Gurney flaps on its rear wing to improve cornering grip during endurance races. Formula 1 cars from the 1970s, such as the Lotus 79, also employed Gurney flaps to optimize aerodynamic performance and balance.

Gurney Flap Applications in Formula 1

Gurney flaps are extensively used in Formula 1 to enhance downforce by creating a controlled vortex at the rear wing edge, improving overall aerodynamic efficiency. These small, right-angled tabs increase rear wing pressure without significantly increasing drag, optimizing cornering performance and stability at high speeds. Teams strategically adjust Gurney flap size and angle to balance aerodynamic grip and top speed depending on circuit characteristics.

Gurney Flaps in Sports Cars and Road Vehicles

Gurney flaps enhance downforce and stability in sports cars by creating controlled airflow separation over rear spoilers and wings, improving cornering grip at high speeds. Road vehicles use smaller Gurney flaps to optimize aerodynamic efficiency, reducing drag while maintaining sufficient downforce for safety and fuel economy. This aerodynamic device is critical in balancing performance and efficiency in modern automotive design.

Effects of Gurney Flaps on Downforce and Drag

Gurney flaps, small aerodynamic tabs mounted on the trailing edge of automotive spoilers or wings, significantly increase downforce by enhancing airflow separation and creating a higher pressure differential. Their effect typically boosts rear traction and cornering stability, crucial for high-performance vehicles and race cars. While increasing downforce, Gurney flaps also cause a moderate rise in aerodynamic drag, impacting fuel efficiency and top speed, necessitating careful balance in design optimization.

Real-World Examples: Gurney Flaps on GT Cars

Gurney flaps on GT cars enhance downforce and improve cornering stability by increasing aerodynamic grip without significantly increasing drag, crucial for maintaining high speeds on race tracks. Notable examples include the Porsche 911 GT3 and the Ferrari 488 GT3, which use gurney flaps on their rear wings to optimize airflow and boost performance during competitive racing. These devices contribute to better traction and braking efficiency, making them essential aerodynamic components in professional motorsport.

Gurney Flap Material Choices and Design Variations

Gurney flap material choices in automotive aerodynamics typically include lightweight aluminum and carbon fiber composites to balance durability and weight reduction. Design variations range from fixed vertical tabs to adjustable and perforated flaps, enabling precise control over downforce and drag reduction. Optimizing material and geometry enhances vehicle stability and fuel efficiency at high speeds.

Future Trends in Gurney Flap Usage in the Automotive Industry

Future trends in gurney flap usage in the automotive industry emphasize enhanced aerodynamic efficiency for electric and autonomous vehicles, optimizing drag reduction and stability at high speeds. Advanced computational fluid dynamics (CFD) and adaptive materials enable real-time adjustment of gurney flap angles, improving energy consumption and handling performance. Integration with active aerodynamic systems supports next-generation vehicle designs focused on sustainability and performance optimization.

example of gurney flap in aerodynamics Infographic

samplerz.com

samplerz.com