The cowl in automotive body design refers to the front section of a vehicle's body located between the hood and the windshield. It houses essential components such as the windshield wipers, ventilation intake, and sometimes the dashboard structural frame. This area is crucial for protecting the internal cabin from water ingress and managing airflow into the vehicle's HVAC system. Cowl panels are typically made from stamped steel or composite materials and are designed to provide structural rigidity to the front body section. They play a key role in vehicle aerodynamics by channeling air smoothly over the windshield and reducing wind noise. The cowl also acts as a mounting point for various accessories, making it an integral part of the automotive body structure.

Table of Comparison

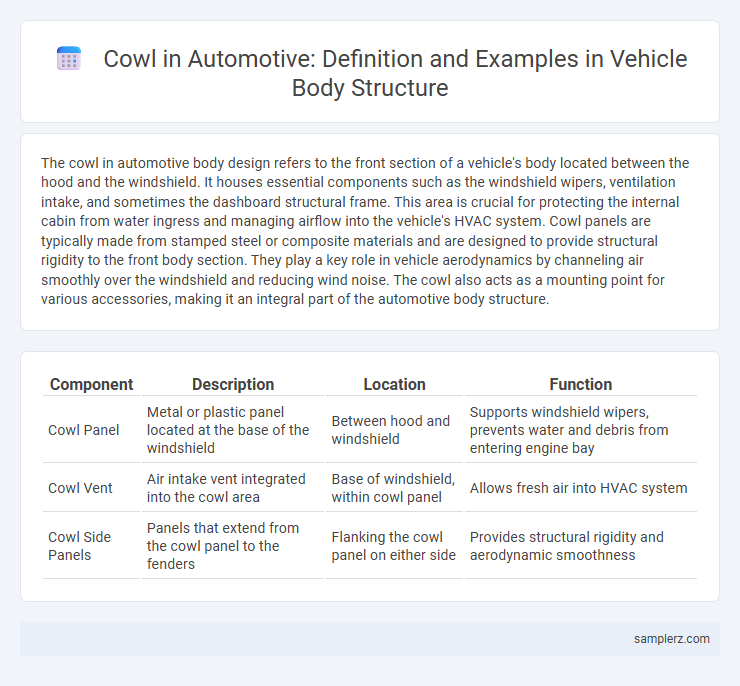

| Component | Description | Location | Function |

|---|---|---|---|

| Cowl Panel | Metal or plastic panel located at the base of the windshield | Between hood and windshield | Supports windshield wipers, prevents water and debris from entering engine bay |

| Cowl Vent | Air intake vent integrated into the cowl area | Base of windshield, within cowl panel | Allows fresh air into HVAC system |

| Cowl Side Panels | Panels that extend from the cowl panel to the fenders | Flanking the cowl panel on either side | Provides structural rigidity and aerodynamic smoothness |

Introduction to Cowl in Automotive Body Design

The cowl in automotive body design is a structural component located at the base of the windshield, serving as a crucial interface between the engine compartment and passenger cabin. Its design enhances vehicle rigidity, improves aerodynamics, and provides mounting points for windshield wipers and ventilation systems. Optimizing the cowl structure contributes to safety, noise reduction, and overall vehicle performance in modern car manufacturing.

Key Functions of the Cowl in Vehicles

The cowl in automotive design serves as a structural component located between the hood and the windshield, providing crucial support for windshield installation and enhancing vehicle rigidity. It plays a key role in channeling air into the HVAC system for cabin ventilation while preventing water and debris from entering the engine bay. Furthermore, the cowl contributes to occupant safety by reinforcing the front firewall and facilitating proper airflow management to optimize engine cooling efficiency.

Common Materials Used for Automotive Cowls

Automotive cowls are commonly manufactured using galvanized steel, aluminum, and composite materials such as fiberglass reinforced plastic (FRP), providing a balance of strength, durability, and corrosion resistance. High-strength steel offers superior impact resistance, while aluminum reduces overall vehicle weight for improved fuel efficiency. Advanced composites enhance design flexibility and contribute to noise reduction within the vehicle cabin.

Placement and Structure of the Cowl Panel

The cowl panel is positioned between the vehicle's windshield and the hood, serving as a critical structural component that supports the base of the windshield and houses ventilation intakes. Constructed from stamped steel or composite materials, the cowl panel integrates with the firewall and fenders to enhance rigidity and improve occupant protection. Its design channels airflow into the cabin ventilation system while preventing water ingress into engine compartments, ensuring both performance and durability.

Example: Traditional Steel Cowl in Sedans

The traditional steel cowl in sedans is a crucial structural component located at the base of the windshield, providing rigidity and support to the vehicle's body. It serves as a mounting point for windshield wipers and helps channel water away from the engine bay and passenger compartment. Steel cowls are valued for their durability, corrosion resistance, and ability to absorb impact in collisions, contributing to overall vehicle safety and structural integrity.

Example: Integrated Plastic Cowl in Modern SUVs

The integrated plastic cowl in modern SUVs serves as a lightweight, durable component that enhances aerodynamics while protecting the windshield wiper mechanism and cabin air intake from debris and water. Its design supports advanced sealing techniques to reduce noise and improve thermal insulation within the vehicle cabin. This plastic cowl significantly contributes to vehicle weight reduction and cost efficiency compared to traditional metal cowls.

Example: Cowl Induction Systems in Performance Cars

Cowl induction systems in performance cars leverage the high-pressure air at the base of the windshield to feed the engine with cooler, denser air, improving combustion efficiency and power output. These systems typically feature a raised or scooped cowl section that directs airflow directly into the intake manifold. Popular models such as the Chevrolet Camaro SS and Ford Mustang GT employ cowl induction to enhance throttle response and overall engine performance.

The Role of Cowl in Vehicle Aerodynamics

The cowl in vehicle body design plays a critical role in optimizing aerodynamics by managing airflow between the windshield and hood, reducing drag and turbulence. Its precise shape directs air smoothly over the vehicle's surface, enhancing fuel efficiency and stability at high speeds. Effective cowl design also improves engine cooling by channeling airflow to the radiator while minimizing aerodynamic lift.

Cowl Panel Maintenance and Replacement Tips

Cowl panels in automotive bodywork protect the windshield wipers and engine compartment from debris and water ingress. Regular inspection for rust or damage ensures optimal sealing and prevents corrosion, which can lead to costly repairs. For replacement, carefully remove the windshield wipers and trim, align the new cowl panel precisely, and secure all fasteners to maintain structural integrity and weatherproofing.

Future Trends in Cowl Design for Automobiles

Future trends in cowl design for automobiles emphasize enhanced aerodynamics and improved structural integrity to reduce drag and increase fuel efficiency. Innovative materials like carbon fiber composites and advanced polymers are being integrated to decrease weight while maintaining durability. Incorporation of sensor arrays and smart vents in cowl structures supports advanced driver-assistance systems (ADAS) and improved cabin ventilation control.

example of cowl in body Infographic

samplerz.com

samplerz.com