A plenum in an automotive intake manifold serves as a central chamber that distributes air evenly to the engine's cylinders. This component plays a critical role in optimizing air flow, ensuring consistent air pressure, and enhancing combustion efficiency. Data shows that well-designed plenums can improve engine performance by reducing air turbulence and increasing volumetric efficiency. In modern vehicles, plenums are often integrated with throttle bodies and intake runners to maximize air delivery during varying engine loads. Automotive engineers use computational fluid dynamics (CFD) simulations to analyze plenum design, focusing on parameters like air velocity and pressure distribution. Performance gains from an optimized plenum include improved throttle response, increased horsepower, and better fuel economy.

Table of Comparison

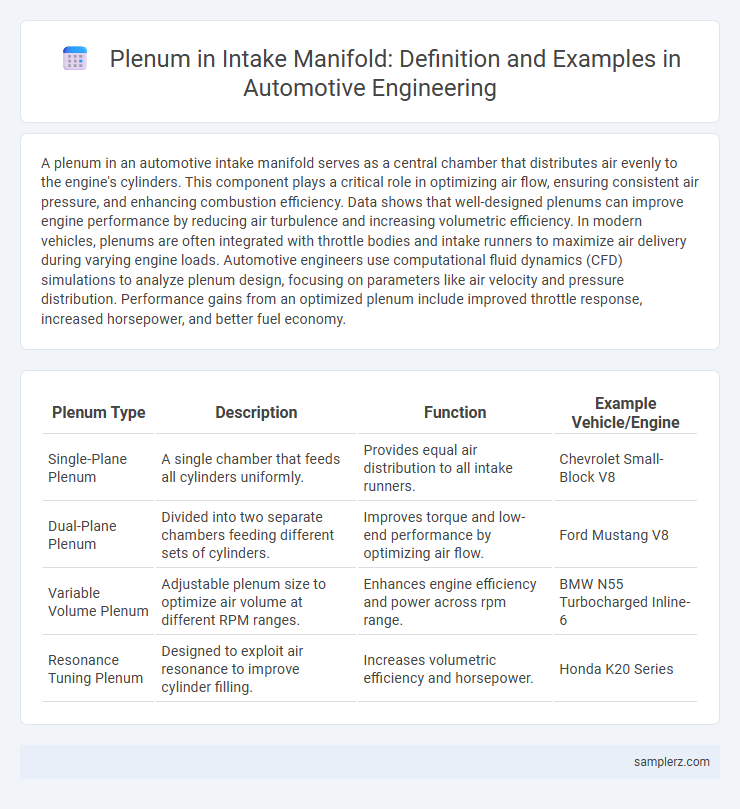

| Plenum Type | Description | Function | Example Vehicle/Engine |

|---|---|---|---|

| Single-Plane Plenum | A single chamber that feeds all cylinders uniformly. | Provides equal air distribution to all intake runners. | Chevrolet Small-Block V8 |

| Dual-Plane Plenum | Divided into two separate chambers feeding different sets of cylinders. | Improves torque and low-end performance by optimizing air flow. | Ford Mustang V8 |

| Variable Volume Plenum | Adjustable plenum size to optimize air volume at different RPM ranges. | Enhances engine efficiency and power across rpm range. | BMW N55 Turbocharged Inline-6 |

| Resonance Tuning Plenum | Designed to exploit air resonance to improve cylinder filling. | Increases volumetric efficiency and horsepower. | Honda K20 Series |

Overview of Plenum in Intake Manifolds

The plenum in an intake manifold serves as a central chamber that evenly distributes the air-fuel mixture to each cylinder, optimizing engine performance and fuel efficiency. Designed to reduce air turbulence and pressure fluctuations, the plenum enhances volumetric efficiency and supports consistent combustion across all cylinders. Advanced intake manifold designs incorporate variable plenum volumes to improve torque delivery and power output at different engine speeds.

Purpose and Function of the Plenum Chamber

The plenum chamber in an intake manifold serves as a central air reservoir that evenly distributes incoming air to each cylinder, ensuring balanced air flow and optimal engine performance. It helps to stabilize air pressure fluctuations caused by the opening and closing of throttle valves, enhancing throttle response and improving fuel-air mixture consistency. By promoting uniform air distribution, the plenum chamber contributes to increased combustion efficiency and reduced emissions in automotive engines.

Common Plenum Designs in Automotive Engines

Common plenum designs in automotive engines include single-chamber and multi-chamber configurations, optimizing airflow distribution to each cylinder. Single-chamber plenums use a large, centralized cavity to evenly supply air, enhancing volumetric efficiency and throttle response. Multi-chamber plenums improve tuning for performance engines by incorporating separate chambers that reduce pressure pulsations and increase torque across varying RPM ranges.

Material Choices for Intake Plenums

Intake plenums in automotive manifolds are commonly made from aluminum due to its lightweight and excellent thermal conductivity, which helps reduce heat absorption and improve air density. Composite materials, such as glass-reinforced nylon, offer advantages in weight reduction and design flexibility while maintaining structural strength and thermal resistance. Advanced polymers also provide corrosion resistance and lower production costs, making them popular choices for high-performance and mass-market vehicles.

Single vs. Dual Plenum Intake Manifolds

Single plenum intake manifolds feature one central chamber distributing air evenly to all cylinders, promoting consistent airflow and simpler design, which benefits lower to mid-range engine speeds. Dual plenum intake manifolds split the airflow into two separate chambers, enhancing airflow tuning and improving performance at higher RPMs by reducing air resistance and increasing volumetric efficiency. These configurations impact engine response, power delivery, and fuel efficiency, making the choice critical for optimizing engine characteristics in various automotive applications.

Impact of Plenum Volume on Engine Performance

The plenum in an intake manifold acts as a reservoir that balances air distribution to the engine's cylinders, directly affecting volumetric efficiency and throttle response. Increased plenum volume can enhance low-end torque by allowing more air to accumulate, but excessive size may reduce throttle sensitivity and high-RPM power output. Optimizing plenum volume is vital for achieving a balanced engine performance, improving both torque curves and fuel efficiency in automotive applications.

Real-World Examples of Plenum in Popular Cars

The plenum in the intake manifold of the 2022 Toyota Camry optimizes air distribution to improve engine efficiency and throttle response. In the Ford Mustang GT, the dual plenum design enhances airflow for increased horsepower and torque, supporting performance driving. The Honda Civic Type R features a lightweight composite plenum that reduces heat soak and delivers consistent power output under high RPM conditions.

Plenum Modifications for Aftermarket Performance

Plenum modifications in aftermarket intake manifolds enhance airflow distribution, improving engine volumetric efficiency and horsepower output. Enlarging or reshaping the plenum chamber reduces intake air turbulence, providing a more consistent air-fuel mixture for combustion. Performance enthusiasts often install adjustable or dual-plane plenums to optimize torque curves and throttle response across a wider RPM range.

Diagnosis: Plenum-Related Issues and Symptoms

A malfunctioning plenum in an intake manifold can cause uneven air distribution, leading to rough idling, reduced engine performance, and increased fuel consumption. Diagnosing plenum-related issues often involves inspecting for vacuum leaks, cracks, or carbon buildup that disrupt airflow balance. Using a smoke test or pressure gauge can effectively identify these faults to ensure optimal engine efficiency and throttle response.

Innovations in Plenum Technology for Modern Engines

Innovations in plenum technology for intake manifolds include variable geometry designs that optimize airflow distribution and enhance engine breathing efficiency. Advanced materials such as lightweight composites reduce overall weight while improving thermal management and durability. Integration of active airflow control components, like adjustable valves, enables dynamic tuning of the intake system to maximize performance and fuel economy across different driving conditions.

example of plenum in intake manifold Infographic

samplerz.com

samplerz.com