A squib in an airbag system is a small explosive device responsible for igniting the gas generator that inflates the airbag during a collision. This component contains a bridge wire and a pyrotechnic charge, which, when triggered by the airbag control unit, rapidly produces gas to deploy the airbag within milliseconds. The squib ensures the airbag inflates at the precise moment to protect vehicle occupants from impact injuries. Squibs are critical entities in automotive safety systems, as their performance directly impacts airbag deployment reliability and timing. Data from crash sensors and the vehicle's ECU determines the activation of the squib, reflecting the integration of sensor technology and pyrotechnic engineering in modern vehicles. Manufacturers rigorously test squib functionality to comply with safety standards and reduce false deployments or failures in real crash scenarios.

Table of Comparison

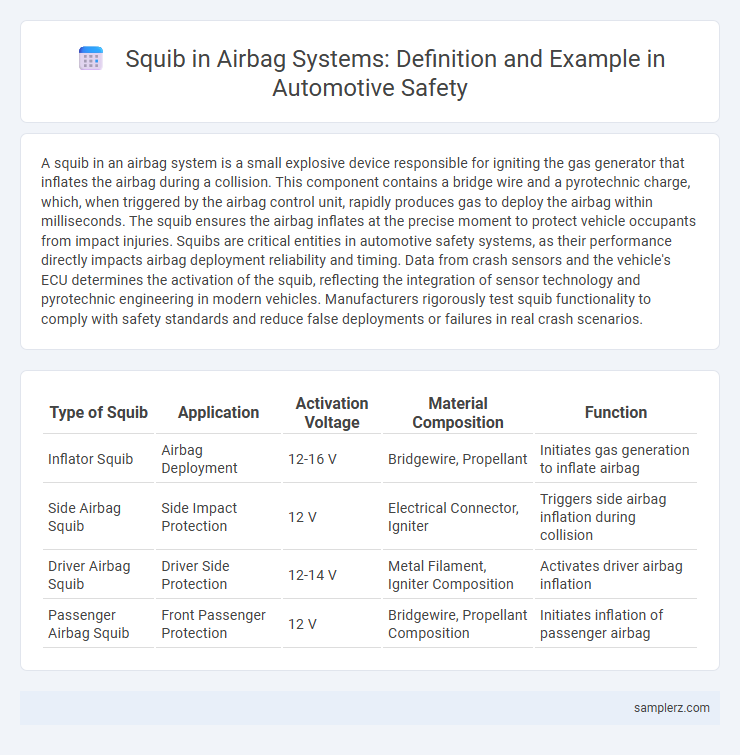

| Type of Squib | Application | Activation Voltage | Material Composition | Function |

|---|---|---|---|---|

| Inflator Squib | Airbag Deployment | 12-16 V | Bridgewire, Propellant | Initiates gas generation to inflate airbag |

| Side Airbag Squib | Side Impact Protection | 12 V | Electrical Connector, Igniter | Triggers side airbag inflation during collision |

| Driver Airbag Squib | Driver Side Protection | 12-14 V | Metal Filament, Igniter Composition | Activates driver airbag inflation |

| Passenger Airbag Squib | Front Passenger Protection | 12 V | Bridgewire, Propellant Composition | Initiates inflation of passenger airbag |

Understanding the Role of Squib in Airbag Systems

The squib in airbag systems serves as the essential igniter, rapidly generating the gas needed to inflate the airbag upon collision detection. This small pyrotechnic device receives an electrical signal from the crash sensor, triggering a controlled explosion that inflates the airbag within milliseconds. Proper functioning of the squib is critical for occupant safety, ensuring timely deployment to reduce injury risk during an automotive accident.

What Is a Squib? Definition and Function

A squib in an airbag system is a small explosive device that initiates the rapid deployment of the airbag upon collision detection. Its function is to ignite the inflator, producing gas that fills the airbag within milliseconds to protect occupants during a crash. Squibs are critical components in automotive safety systems, ensuring timely and effective airbag activation.

Squib Activation Process in Airbag Deployment

The squib activation process in airbag deployment involves an electric current triggering a small explosive charge within the squib, which rapidly ignites the inflator gas. This controlled ignition releases nitrogen or argon gas, inflating the airbag within milliseconds to protect the vehicle occupant during a collision. Precise timing and reliable electrical signals are critical to ensure the squib activates only during impact events, minimizing false deployments and maximizing safety.

Key Components of Squib Mechanism

The squib in an airbag system consists primarily of a firing element, often a bridgewire, which ignites the pyrotechnic charge upon receiving an electric current. Key components include the initiator housing, which contains the bridgewire and the explosive material, and the electrical connectors that link the squib to the vehicle's airbag control unit. This mechanism ensures rapid deployment of the airbag by converting electrical signals into a controlled explosion that inflates the cushion in milliseconds.

Types of Squibs Used in Automotive Airbags

Automotive airbags commonly use pyrotechnic squibs, which include bridgewire and metal film types, to trigger rapid gas generation for airbag deployment. Bridgewire squibs utilize a thin wire that heats up and ignites the gas generant, while metal film squibs rely on a resistive film element for ignition. These squib types are designed to ensure precise timing, reliability, and safety in crash situations.

Step-by-Step Example: Squib Triggering in a Collision

In a collision, the vehicle's crash sensors detect abrupt deceleration and send an electrical signal to the airbag control unit. The control unit then triggers the squib, an electrically heated resistor causing a rapid chemical reaction that ignites the inflator's gas generant. This reaction produces gas that inflates the airbag within milliseconds, cushioning the occupant and reducing injury risk.

Importance of Squib Reliability for Safety

The squib in an airbag system acts as the critical initiator that triggers rapid gas generation to inflate the airbag during a collision. High squib reliability is essential to ensure timely and consistent deployment, directly impacting occupant protection and reducing injury severity. Rigorous testing and quality control of squib components are fundamental to maintaining automotive safety standards and preventing deployment failures.

Common Squib Failure Modes and Diagnostics

Common squib failure modes in automotive airbags include open circuits, short circuits, and resistance deviations that prevent proper ignition of the inflator. Diagnostics often involve measuring squib resistance and continuity using specialized scan tools or multimeters to detect electrical anomalies. Timely identification of these failures is critical to ensure reliable airbag deployment and occupant safety during collisions.

Real-World Cases of Squib Implementation

Squib devices in automotive airbags use precise pyrotechnic charges to trigger rapid gas inflation upon collision detection, ensuring occupant safety. Real-world cases like the Toyota Camry and Honda Accord demonstrate how squib systems integrate with crash sensors to deploy airbags within milliseconds of impact. Continuous advancements in squib technology improve response times and reliability, reducing injury rates in frontal crashes.

Future Innovations in Airbag Squib Technology

Future innovations in airbag squib technology prioritize the development of low-energy, high-reliability initiators that reduce power consumption while enhancing deployment precision. Advanced nanomaterials and MEMS-based squibs are being engineered to improve responsiveness and safety, enabling faster airbag inflation with minimal false triggers. Integration of smart sensors and AI algorithms promises adaptive deployment systems that tailor airbag activation based on crash severity and occupant positioning.

example of squib in airbag Infographic

samplerz.com

samplerz.com