Honing in a cylinder is a precision machining process used to improve the surface finish and geometric accuracy of engine cylinders. This technique employs abrasive stones that rotate and move reciprocally within the cylinder bore to remove small amounts of material, achieving the desired diameter and crosshatch pattern. Proper honing ensures optimal piston ring sealing, reduced oil consumption, and enhanced engine performance. The honing process involves specific parameters such as grit size, pressure, and stroke length, which are critical to achieving consistent cylinder surface texture. Automotive manufacturers rely on honing to meet strict tolerances for cylinder roundness and surface roughness, which directly affect engine efficiency and lifespan. Data from honing operations often includes measurements of bore diameter, surface roughness (Ra), and crosshatch angle to ensure quality control and compliance with design specifications.

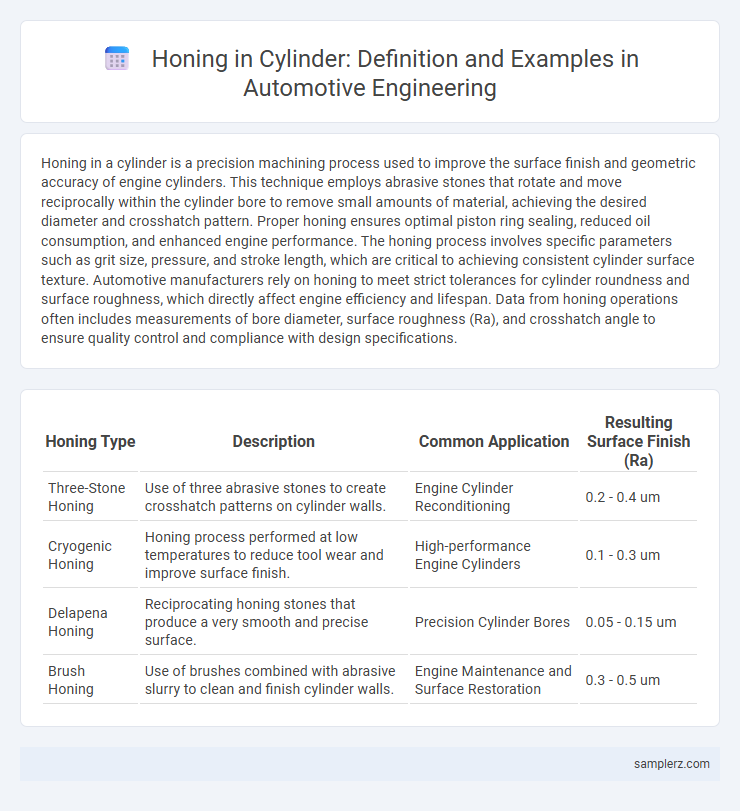

Table of Comparison

| Honing Type | Description | Common Application | Resulting Surface Finish (Ra) |

|---|---|---|---|

| Three-Stone Honing | Use of three abrasive stones to create crosshatch patterns on cylinder walls. | Engine Cylinder Reconditioning | 0.2 - 0.4 um |

| Cryogenic Honing | Honing process performed at low temperatures to reduce tool wear and improve surface finish. | High-performance Engine Cylinders | 0.1 - 0.3 um |

| Delapena Honing | Reciprocating honing stones that produce a very smooth and precise surface. | Precision Cylinder Bores | 0.05 - 0.15 um |

| Brush Honing | Use of brushes combined with abrasive slurry to clean and finish cylinder walls. | Engine Maintenance and Surface Restoration | 0.3 - 0.5 um |

Introduction to Cylinder Honing in Automotive Engines

Cylinder honing in automotive engines involves precision abrasive machining that refines the interior surface of engine cylinders to achieve an optimal crosshatch pattern. This process enhances oil retention and improves piston ring sealing, which directly contributes to engine efficiency, reduced oil consumption, and extended component lifespan. Advanced honing techniques use diamond or silicon carbide stones to maintain tight dimensional tolerances and surface finish requirements critical for high-performance and longevity in modern engines.

Importance of Honing for Engine Performance

Honing in cylinder walls creates a precise crosshatch pattern that improves oil retention and reduces friction between piston rings and the cylinder surface. This process ensures optimal sealing, preventing blow-by gases and enhancing compression, which directly contributes to engine efficiency and power. Proper honing extends engine lifespan by minimizing wear and maintaining consistent performance under varying operating conditions.

Types of Honing Processes Used in Cylinder Walls

Cylinder wall honing typically involves two main types of honing processes: two-stone and three-stone honing. Two-stone honing utilizes a pair of abrasive stones to create a crosshatch pattern that enhances oil retention and improves piston ring sealing. Three-stone honing employs an additional stone for greater surface contact and precision, resulting in a more uniform finish and tighter dimensional tolerances critical for high-performance engines.

Tools and Equipment for Cylinder Honing

Precision cylinder honing requires specialized tools such as rigid honing stones, flexible honing brushes, and adjustable torque wrenches to achieve uniform surface finish and optimal crosshatch pattern. Equipment like hone stands or bench-mounted honing machines ensures stable operation and precise control over bore geometry. Advanced diamond or silicon carbide abrasive stones are preferred for maintaining dimensional accuracy and enhancing engine performance by reducing friction and improving oil retention.

Step-by-Step Example of Cylinder Honing

Cylinder honing involves using abrasive stones mounted on a honing tool to create a precise crosshatch pattern on the cylinder walls, improving oil retention and piston ring sealing. First, the cylinder is thoroughly cleaned and measured to determine the target bore size. Next, the honing machine is set to the correct speed and feed rate before gradually honing the cylinder while regularly measuring the surface finish and diameter for accuracy.

Surface Finish Achieved by Cylinder Honing

Cylinder honing achieves a surface finish with a crosshatch pattern that optimizes oil retention and enhances piston ring sealing, typically reaching roughness values between 0.2 to 0.4 micrometers Ra. This precise surface texture reduces friction and wear, improving engine efficiency and longevity. Controlled honing parameters ensure consistent micro-finish crucial for optimal engine performance in automotive applications.

Common Mistakes in Honing Cylinders

Common mistakes in honing cylinders include using an incorrect honing stone grit, which can lead to uneven surface finishes and impaired cylinder sealing. Inadequate lubrication during the honing process causes excessive heat and surface damage, reducing engine efficiency and lifespan. Failing to maintain proper honing angles results in improper crosshatch patterns, negatively affecting oil retention and piston ring seating.

Quality Control and Measurement in Cylinder Honing

Cylinder honing ensures optimal surface finish and precise geometry critical for engine performance and longevity. Quality control involves measuring the crosshatch angle, surface roughness (Ra), and dimensional tolerances using advanced profilometers and coordinate measuring machines (CMM). Accurate measurement during honing detects deviations early, preventing wear, improving oil retention, and maintaining combustion efficiency.

Maintenance Tips After Cylinder Honing

After cylinder honing, regularly inspect the cylinder walls for uniform crosshatch patterns to ensure optimal oil retention and ring sealing. Use high-quality oils with the correct viscosity to prevent premature wear and maintain smooth engine performance. Schedule periodic compression tests to monitor cylinder health and detect potential issues early for effective maintenance.

Benefits of Properly Honed Engine Cylinders

Properly honed engine cylinders create an optimal surface finish that enhances oil retention and improves piston ring sealing, resulting in increased engine efficiency and reduced oil consumption. This precise surface texture minimizes friction and wear, extending the engine's lifespan and maintaining consistent compression levels. Enhanced combustion efficiency from correctly honed cylinders contributes to better fuel economy and lower emissions, maximizing overall vehicle performance.

example of honing in cylinder Infographic

samplerz.com

samplerz.com