A wastegate in a turbocharger is a crucial component that controls exhaust flow to regulate boost pressure. It functions by diverting excess exhaust gases away from the turbine wheel, preventing over-boost conditions that can damage the engine. The wastegate operates either as an internal valve integrated into the turbocharger housing or as an external valve mounted separately on the exhaust manifold. Modern wastegates are often electronically controlled to improve precision and response time, enhancing engine performance and efficiency. Data from sensors such as boost pressure and engine load help the engine control unit modulate the wastegate position. This regulation ensures optimal turbocharger operation, maintaining engine power while managing heat and mechanical stress.

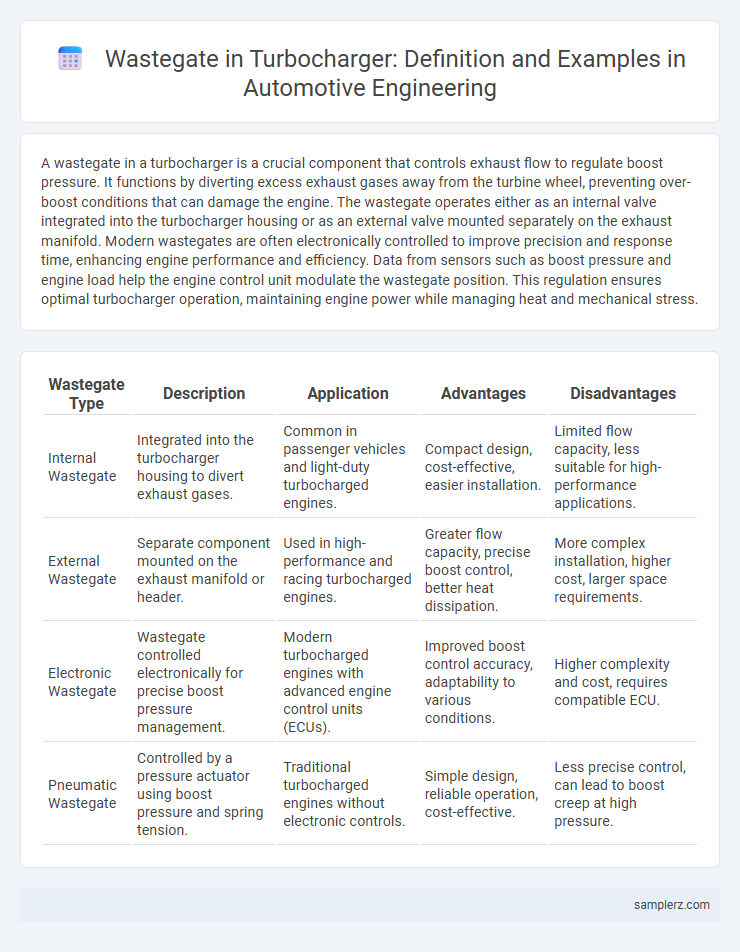

Table of Comparison

| Wastegate Type | Description | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Internal Wastegate | Integrated into the turbocharger housing to divert exhaust gases. | Common in passenger vehicles and light-duty turbocharged engines. | Compact design, cost-effective, easier installation. | Limited flow capacity, less suitable for high-performance applications. |

| External Wastegate | Separate component mounted on the exhaust manifold or header. | Used in high-performance and racing turbocharged engines. | Greater flow capacity, precise boost control, better heat dissipation. | More complex installation, higher cost, larger space requirements. |

| Electronic Wastegate | Wastegate controlled electronically for precise boost pressure management. | Modern turbocharged engines with advanced engine control units (ECUs). | Improved boost control accuracy, adaptability to various conditions. | Higher complexity and cost, requires compatible ECU. |

| Pneumatic Wastegate | Controlled by a pressure actuator using boost pressure and spring tension. | Traditional turbocharged engines without electronic controls. | Simple design, reliable operation, cost-effective. | Less precise control, can lead to boost creep at high pressure. |

Introduction to Wastegates in Turbochargers

Wastegates in turbochargers regulate exhaust gas flow to control boost pressure and prevent engine overboost, enhancing performance and reliability. Typically, a wastegate valve diverts excess exhaust gases away from the turbine wheel, maintaining optimal turbo speed. This mechanism is crucial in modern automotive turbocharged engines to balance power output and engine safety.

Purpose and Function of Wastegates

Wastegates in turbochargers regulate exhaust gas flow to control boost pressure, preventing engine damage from over-boosting. By diverting excess exhaust gases away from the turbine wheel, wastegates maintain optimal turbocharger speed and improve engine efficiency. This precise control enhances performance and protects turbocharger components from excessive heat and stress.

Types of Wastegates: Internal vs External

Internal wastegates are integrated within the turbocharger housing, utilizing a built-in bypass valve to regulate exhaust flow and prevent overboost, offering compact design and simpler installation. External wastegates are separate units mounted on the exhaust manifold or header, providing precise boost control and adaptability for high-performance applications due to their larger valve size and independent placement. Choosing between internal and external wastegates depends on the vehicle's performance needs, space constraints, and desired boost regulation accuracy.

How a Wastegate Controls Boost Pressure

A wastegate in a turbocharger regulates boost pressure by diverting exhaust gases away from the turbine wheel once a preset pressure is reached, preventing over-boost conditions. This control maintains optimal engine performance and protects components from excessive stress by ensuring the turbocharger operates within safe limits. Precise wastegate operation improves fuel efficiency and prolongs turbocharger lifespan by stabilizing boost levels under varying engine loads.

Common Examples of Wastegates in Popular Turbocharged Cars

Common examples of wastegates in popular turbocharged cars include the external wastegate used in the Subaru WRX STI, which effectively manages boost pressure for performance tuning. The internal wastegate found in the Ford EcoBoost engines offers compact design benefits and efficient boost control in vehicles like the Ford F-150. Additionally, the twin-scroll turbochargers equipped with integrated wastegates in BMW M series models provide enhanced throttle response and improved turbo lag reduction.

Aftermarket Wastegate Options for Performance Upgrades

Aftermarket wastegate options for turbochargers include external manual wastegates, internal electronic wastegates, and variable geometry wastegates, each offering distinct control benefits and upgrade potential. Brands like Tial Sports, Turbosmart, and HKS are leading suppliers recognized for durable and high-response wastegates tailored for increased boost control and reliability. Choosing a performance wastegate upgrade enhances boost regulation precision, reduces turbo lag, and supports higher horsepower targets essential in modified or racing engines.

Wastegate-Related Issues and Troubleshooting

Wastegate-related issues in turbochargers often include stuck valves, actuator failures, and boost leaks that cause inconsistent boost pressure and reduced engine performance. Diagnosing wastegate problems involves inspecting the actuator for proper movement, checking for vacuum leaks, and ensuring the valve opens and closes smoothly. Regular maintenance and prompt troubleshooting can prevent turbocharger overboost, engine knocking, and premature component wear.

The Role of Electronic vs Mechanical Wastegates

Mechanical wastegates utilize a spring-loaded valve to regulate exhaust gas flow and control turbocharger boost pressure, offering simplicity and reliability but limited precision. Electronic wastegates integrate an actuator controlled by the engine control unit (ECU), enabling more accurate boost control and improved performance optimization under varying driving conditions. The precise modulation of electronic wastegates enhances fuel efficiency and reduces turbo lag compared to traditional mechanical systems in modern automotive applications.

Integration of Wastegates in Modern Automotive Turbo Systems

Wastegates in modern automotive turbo systems are integrated to precisely regulate exhaust flow, preventing turbine over-speed and maintaining optimal boost pressure. Advanced electronically controlled wastegates enable real-time adjustments, enhancing engine performance and efficiency while reducing turbo lag. Integration with engine management systems allows seamless coordination between wastegate operation and overall vehicle dynamics for improved drivability.

Future Trends in Wastegate and Turbocharger Technology

Future trends in wastegate and turbocharger technology emphasize electrically actuated wastegates, which offer precise control over boost pressure and improve engine efficiency. Advanced materials such as titanium and ceramics are increasingly used to enhance durability and reduce turbo lag in high-performance applications. Integration with smart engine management systems facilitates real-time adjustments, optimizing power output and reducing emissions in modern automotive engines.

example of wastegate in turbocharger Infographic

samplerz.com

samplerz.com