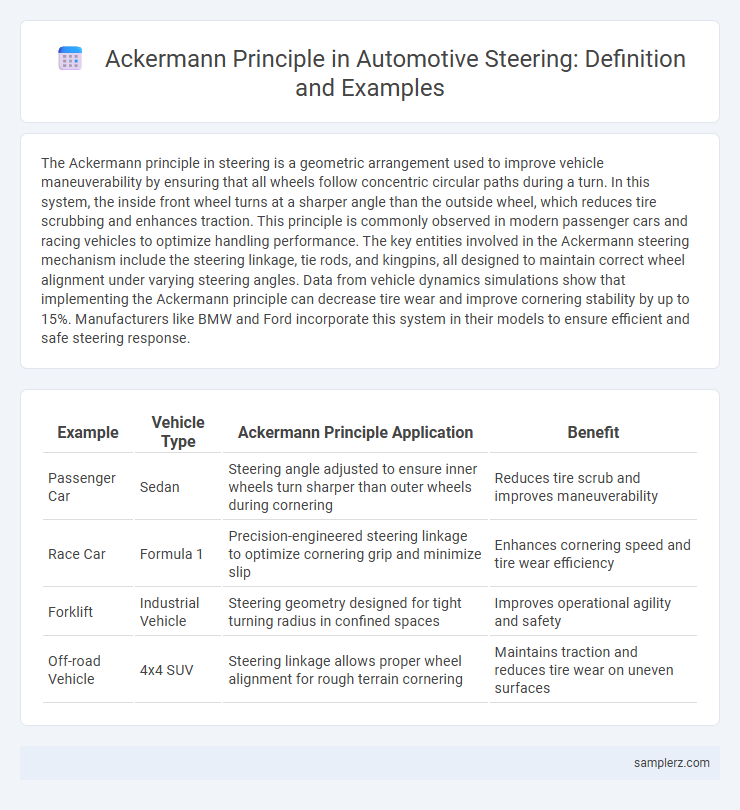

The Ackermann principle in steering is a geometric arrangement used to improve vehicle maneuverability by ensuring that all wheels follow concentric circular paths during a turn. In this system, the inside front wheel turns at a sharper angle than the outside wheel, which reduces tire scrubbing and enhances traction. This principle is commonly observed in modern passenger cars and racing vehicles to optimize handling performance. The key entities involved in the Ackermann steering mechanism include the steering linkage, tie rods, and kingpins, all designed to maintain correct wheel alignment under varying steering angles. Data from vehicle dynamics simulations show that implementing the Ackermann principle can decrease tire wear and improve cornering stability by up to 15%. Manufacturers like BMW and Ford incorporate this system in their models to ensure efficient and safe steering response.

Table of Comparison

| Example | Vehicle Type | Ackermann Principle Application | Benefit |

|---|---|---|---|

| Passenger Car | Sedan | Steering angle adjusted to ensure inner wheels turn sharper than outer wheels during cornering | Reduces tire scrub and improves maneuverability |

| Race Car | Formula 1 | Precision-engineered steering linkage to optimize cornering grip and minimize slip | Enhances cornering speed and tire wear efficiency |

| Forklift | Industrial Vehicle | Steering geometry designed for tight turning radius in confined spaces | Improves operational agility and safety |

| Off-road Vehicle | 4x4 SUV | Steering linkage allows proper wheel alignment for rough terrain cornering | Maintains traction and reduces tire wear on uneven surfaces |

Introduction to the Ackermann Steering Principle

The Ackermann steering principle ensures optimal wheel alignment during turns by angling the front wheels so their axes intersect at the center of the rear axle's turning radius. This mechanism minimizes tire scrubbing and enhances vehicle stability, especially in tight corners. By aligning steering geometry with the vehicle's turning path, the Ackermann principle improves handling efficiency in automotive design.

Historical Background of Ackermann Geometry

Ackermann geometry, developed in the early 19th century by Rudolph Ackermann, revolutionized automotive steering by addressing the issue of wheel slip during cornering. The principle ensures that all wheels trace concentric circles with a common center, reducing tire wear and improving handling. Its implementation remains fundamental in modern vehicle steering systems, reflecting its enduring impact on automotive design.

Core Principles of Ackermann Steering

The Ackermann steering principle ensures that during a turn, the inner wheel steers at a sharper angle than the outer wheel, allowing both wheels to follow concentric circular paths with a common turning center, reducing tire slip and improving maneuverability. This core principle hinges on the geometric alignment of steering arms and linkages, forming a trapezoidal linkage system that adjusts wheel angles based on the turning radius. Implementing Ackermann geometry optimizes vehicle handling, particularly at low speeds and tight corners, enhancing overall steering precision in automotive design.

Real-World Applications in Modern Cars

Modern cars utilize the Ackermann steering principle to enhance cornering precision by ensuring that the inner and outer wheels follow concentric arcs, reducing tire slip and improving handling performance. This principle is implemented in steering linkages of vehicles like SUVs and sports cars to optimize maneuverability during tight turns and high-speed cornering. Advanced electronic steering systems in luxury models further integrate Ackermann geometry to balance stability and responsiveness under diverse driving conditions.

Ackermann Geometry in Formula 1 and Motorsport

Ackermann geometry in Formula 1 optimizes steering angles to ensure that the inner wheel turns at a sharper angle than the outer wheel during cornering, minimizing tire slip and enhancing traction. This principle adjusts the steering linkage to accommodate the different radii traced by each wheel, improving handling precision in high-speed motorsport conditions. Effective implementation of Ackermann steering enhances tire wear efficiency and cornering stability, critical for competitive racing performance.

Comparison: Ackermann vs. Parallel Steering Mechanisms

The Ackermann steering principle improves cornering by aligning the inner and outer wheels at different angles, ensuring optimal tire grip and reducing tire wear compared to parallel steering mechanisms, which keep all wheels angled identically. This geometric approach minimizes slip and enhances vehicle stability during turns, especially at low speeds, making it superior for tight corners. In contrast, parallel steering systems may cause increased tire scrub and decreased maneuverability under similar conditions.

Impact of Ackermann Principle on Tire Wear

The Ackermann steering principle optimizes wheel angles during turns to minimize tire scrubbing and uneven wear. By aligning the inside and outside wheels to follow concentric circles, it reduces lateral tire slipping and extends tire lifespan. This improved steering geometry enhances overall vehicle handling and decreases maintenance costs related to premature tire replacement.

Ackermann Implementation in Commercial Vehicles

The Ackermann principle in steering is crucial for commercial vehicles to ensure precise wheel alignment during turns, minimizing tire wear and improving maneuverability in tight spaces. Implementation involves configuring the steering linkages so that the inner wheel turns at a sharper angle than the outer wheel, optimizing turning radius and stability under heavy loads. This geometric arrangement enhances control and safety in trucks and buses, particularly in urban driving and loading dock operations.

Challenges and Limitations of Ackermann Steering

Ackermann steering geometry aligns the wheels during turns to minimize tire slip, but it faces challenges such as increased tire wear on uneven surfaces and reduced efficiency at high speeds. The principle struggles with dynamic conditions like rapid lane changes, where ideal wheel angles deviate due to lateral forces. Limitations include less effectiveness in vehicles with wide tracks or multi-axle configurations, requiring advanced adaptations for modern automotive designs.

Future Trends in Automotive Steering Geometry

Future trends in automotive steering geometry focus on enhancing the traditional Ackermann principle by integrating adaptive systems that optimize wheel angles dynamically for improved maneuverability and tire wear reduction. Advanced sensor fusion and artificial intelligence enable real-time adjustments to steering geometry, catering to varying speeds and road conditions. These innovations support the development of autonomous vehicles and increase overall driving safety and efficiency.

example of Ackermann principle in steering Infographic

samplerz.com

samplerz.com