A synchromesh in automotive transmission is a crucial mechanism that facilitates smooth gear changes by synchronizing the speeds of the gears. This device uses friction cones and blocking rings to match the rotational speeds of the input and output shafts before engagement. Manual transmissions commonly incorporate synchromesh to prevent gear grinding and ensure efficient power transfer. In practical applications, a synchromesh system is found in cars like the Honda Civic and Ford Mustang, which use it to improve drivability and reduce wear on transmission components. The system's data-driven design optimizes gear shifting times and enhances vehicle performance. Synchromesh technology continues to evolve, integrating advanced materials and precision engineering to support modern automotive demands.

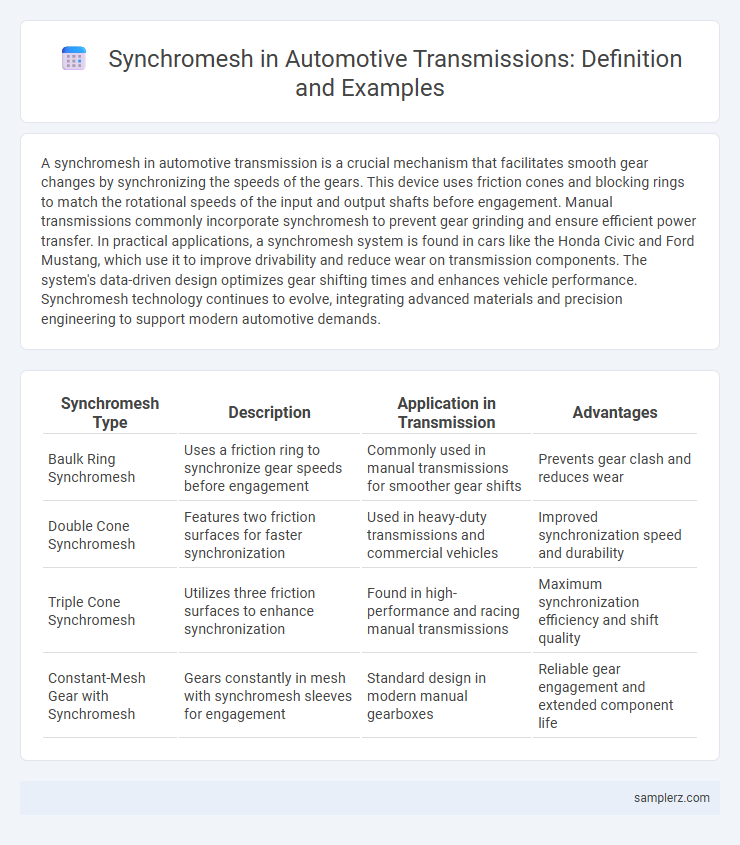

Table of Comparison

| Synchromesh Type | Description | Application in Transmission | Advantages |

|---|---|---|---|

| Baulk Ring Synchromesh | Uses a friction ring to synchronize gear speeds before engagement | Commonly used in manual transmissions for smoother gear shifts | Prevents gear clash and reduces wear |

| Double Cone Synchromesh | Features two friction surfaces for faster synchronization | Used in heavy-duty transmissions and commercial vehicles | Improved synchronization speed and durability |

| Triple Cone Synchromesh | Utilizes three friction surfaces to enhance synchronization | Found in high-performance and racing manual transmissions | Maximum synchronization efficiency and shift quality |

| Constant-Mesh Gear with Synchromesh | Gears constantly in mesh with synchromesh sleeves for engagement | Standard design in modern manual gearboxes | Reliable gear engagement and extended component life |

Introduction to Synchromesh Systems in Automotive Transmissions

Synchromesh systems in automotive transmissions enable smooth gear shifting by synchronizing the speeds of the input shaft and the gear before engagement, reducing wear and improving driving comfort. Key components include synchronizer rings made from friction materials and sliding hubs that align gears precisely. Widely used in manual transmissions, synchromesh technology enhances durability and performance by preventing gear clash and facilitating seamless power transfer.

How Synchromesh Works in Manual Gearboxes

Synchromesh in manual gearboxes uses friction cones to synchronize the speed of the gear to the shaft before engagement, ensuring smooth shifting without grinding. When a driver shifts gears, the synchromesh ring matches the rotational speed of the gears by creating friction, allowing seamless gear engagement. This mechanism improves driving comfort and prolongs transmission lifespan by preventing gear clash during shifts.

Key Components of a Synchromesh Transmission

Synchromesh transmissions rely on critical components such as the synchronizer ring, hub, sleeve, and blocking ring to enable smooth gear engagement by matching the rotational speeds of gears. The synchronizer ring uses friction to synchronize gear speeds, while the hub and sleeve facilitate the sliding motion that locks the gears in place. Blocking rings prevent gear clash by temporarily holding the sleeve until synchronization is achieved, ensuring efficient and quiet shifting in automotive manual transmissions.

Synchromesh vs Non-Synchromesh Transmissions

Synchromesh transmissions use synchronizer rings to match gear speeds before engagement, reducing gear clash and enabling smoother shifts, which is common in modern manual automotive gearboxes. Non-synchromesh transmissions lack these synchronizers, often requiring double clutching to synchronize gears manually, typically found in heavy-duty trucks or older vehicles. The presence of synchromesh significantly enhances driving comfort and transmission longevity by preventing gear grinding and easing gear changes.

Real-World Examples of Synchromesh Mechanisms

Real-world examples of synchromesh mechanisms are found in manual transmissions of vehicles like the Honda Civic and Ford Mustang, where synchronizer rings match gear speeds for smooth shifting. Motorcycles such as the Yamaha YZF-R3 also employ synchromesh to coordinate gear engagement and reduce gear clash. These systems enhance drivability by enabling seamless gear transitions and extending transmission lifespan.

Advantages of Synchromesh in Modern Vehicles

Synchromesh in modern vehicle transmissions enhances gear shifting by synchronizing the speeds of gears before engagement, reducing wear and tear on transmission components. This technology provides smoother and quieter shifts, improving overall driving comfort and control. It also extends the lifespan of the transmission system by minimizing gear clash and mechanical stress.

Common Vehicles Using Synchromesh Transmissions

Common vehicles using synchromesh transmissions include most manual passenger cars like the Honda Civic, Toyota Corolla, and Ford Fiesta, which utilize synchromesh gears to enable smooth gear shifts. Light trucks and SUVs, such as the Jeep Wrangler and Toyota Tacoma, also frequently employ synchromesh systems to enhance drivability and reduce gear clash. Synchromesh technology remains a standard feature in manual transmissions across a wide range of everyday vehicles due to its reliability and efficiency.

Signs of Synchromesh Wear or Failure

Symptoms of synchromesh wear include difficulty shifting gears, grinding noises during gear changes, and increased resistance or stiffness in the gear lever, indicating synchronization issues in the transmission system. Worn synchromesh rings often cause gear clash or delayed engagement, which impacts overall driving smoothness and vehicle performance. Regular inspection of these signs can prevent further transmission damage and costly repairs.

Maintenance Tips for Synchromesh Gearboxes

Regularly check the transmission fluid level and quality to ensure optimal lubrication of synchromesh components and prevent gear wear. Inspect synchronizer rings for signs of wear or damage, as maintaining their condition is crucial for smooth gear shifts and preventing grinding. Use manufacturer-recommended fluids and schedule periodic gearbox servicing to prolong the lifespan of synchromesh gearboxes and maintain transmission performance.

Future Trends in Synchromesh Transmission Technology

Emerging synchromesh transmission technology integrates advanced materials like carbon nanotubes and ceramic composites to reduce friction and enhance durability. Electrification trends drive the development of electronically controlled synchromesh systems, enabling faster and more precise gear shifts. These innovations contribute to improved fuel efficiency and smoother vehicle performance in next-generation automotive drivetrains.

example of synchromesh in transmission Infographic

samplerz.com

samplerz.com