A stroke in a crankshaft refers to the complete movement of the piston from the top dead center (TDC) to the bottom dead center (BDC) within the engine cylinder. In automotive engines, the crankshaft converts the linear motion of the pistons into rotational motion to power the vehicle. Commonly, a four-stroke engine features four distinct strokes: intake, compression, power, and exhaust, each contributing to the engine's power cycle. The stroke length is a critical measurement in crankshaft design, determining the engine's displacement and performance characteristics. For example, a 4-stroke crankshaft has two complete revolutions per power cycle, with the piston moving up and down twice. Precise stroke measurements influence fuel efficiency, torque, and overall engine durability in automotive applications.

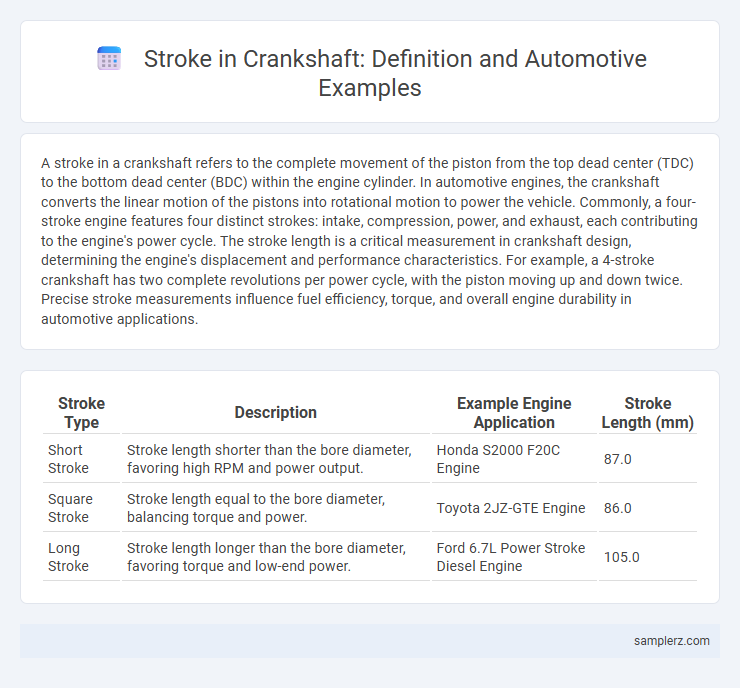

Table of Comparison

| Stroke Type | Description | Example Engine Application | Stroke Length (mm) |

|---|---|---|---|

| Short Stroke | Stroke length shorter than the bore diameter, favoring high RPM and power output. | Honda S2000 F20C Engine | 87.0 |

| Square Stroke | Stroke length equal to the bore diameter, balancing torque and power. | Toyota 2JZ-GTE Engine | 86.0 |

| Long Stroke | Stroke length longer than the bore diameter, favoring torque and low-end power. | Ford 6.7L Power Stroke Diesel Engine | 105.0 |

Understanding Stroke in Automotive Crankshafts

A stroke in an automotive crankshaft refers to the distance the piston travels within the cylinder from top dead center (TDC) to bottom dead center (BDC). This linear movement directly affects engine displacement and power output by determining the volume of the combustion chamber. Proper understanding of stroke length is crucial for optimizing engine performance, fuel efficiency, and emissions control in internal combustion engines.

The Role of Stroke in Engine Performance

Stroke in a crankshaft refers to the distance the piston travels within the cylinder from top dead center to bottom dead center, directly affecting engine displacement and performance. A longer stroke increases torque by allowing more air-fuel mixture intake per cycle, enhancing low-end power and acceleration in vehicles. Optimizing stroke length balances fuel efficiency and power output, crucial for designing engines tailored to specific automotive performance needs.

Measuring Stroke: Key Parameters in Crankshaft Design

Measuring stroke in crankshaft design involves determining the distance the piston travels within the cylinder, which is critical for engine displacement and performance. Key parameters include the crank radius, defined as half the stroke length, and the stroke itself, measured from the top dead center (TDC) to the bottom dead center (BDC) positions of the piston. Accurate measurement ensures optimal engine efficiency, power output, and balance within the crankshaft assembly.

Short Stroke vs. Long Stroke: Comparative Analysis

Short stroke crankshafts feature a bore-to-stroke ratio greater than 1, enhancing engine speed and power output by reducing piston travel distance, which decreases friction and mechanical stress. Long stroke crankshafts, with a bore-to-stroke ratio less than 1, typically produce higher torque at lower RPMs due to increased leverage on the crankshaft, improving fuel efficiency and low-end performance. The choice between short stroke and long stroke designs significantly affects engine characteristics such as power delivery, fuel economy, and durability in automotive applications.

Applications of Varying Stroke Lengths in Vehicles

Varying stroke lengths in crankshafts directly influence engine displacement and torque output, optimizing vehicle performance for different driving conditions. Shorter strokes enable higher engine speeds and improved power delivery, commonly used in sports cars for acceleration and responsiveness. Longer strokes increase torque at lower RPMs, benefiting trucks and SUVs by enhancing towing capacity and fuel efficiency.

Real-World Examples of Stroke Variations in Popular Engines

The 4-stroke cycle is exemplified by the Toyota 2JZ engine, featuring a 86mm stroke that balances power and efficiency in high-performance applications. In contrast, the Chevrolet LS3 V8 utilizes a longer 92mm stroke for increased torque and displacement in muscle cars. Smaller engines like the Honda K20 employ a shorter 86mm stroke to optimize RPM range and fuel efficiency in compact vehicles.

Impact of Stroke on Torque and Horsepower

The stroke length in a crankshaft directly affects the engine's torque and horsepower by determining the piston's travel distance within the cylinder, influencing the engine's displacement and combustion efficiency. A longer stroke increases torque output by providing greater leverage on the crankshaft, enhancing low-end power crucial for towing and acceleration. Conversely, shorter strokes favor higher engine speeds, boosting horsepower potential by enabling faster combustion cycles and power output per minute.

Crankshaft Stroke and Fuel Efficiency Correlation

The crankshaft stroke, defined as the distance the piston travels within the cylinder, directly influences engine displacement and combustion efficiency. A longer stroke typically enhances torque output and fuel combustion stability, which can improve fuel efficiency in low to mid-range RPM conditions. Optimizing crankshaft stroke length balances power delivery and fuel consumption, playing a critical role in advanced engine designs targeting reduced emissions and enhanced mileage.

Common Issues Related to Crankshaft Stroke

Crankshaft stroke issues often result from wear or damage to components like bearings, affecting engine compression and timing. Common problems include crankshaft misalignment, worn journals, and improper stroke length, leading to vibrations and reduced engine performance. Early diagnosis using vibration analysis and precise measurement tools can prevent severe engine damage and costly repairs.

Innovations in Crankshaft Stroke Engineering

Innovations in crankshaft stroke engineering have led to the development of variable stroke mechanisms that optimize engine performance and fuel efficiency across different driving conditions. Advanced materials and precision manufacturing techniques enable longer and more durable strokes without compromising engine balance or increasing emissions. These advancements contribute to enhanced torque delivery and improved combustion dynamics, setting new standards in automotive powertrain design.

example of stroke in crankshaft Infographic

samplerz.com

samplerz.com