In the automotive industry, the cowl is a critical component located at the base of the windshield, serving as a structural barrier between the engine compartment and the passenger cabin. This metal or composite panel is integrated into the vehicle's firewall, providing protection against engine heat, noise, and fumes. The cowl also supports the windshield wipers and channels water away from the engine bay to prevent electrical damage and corrosion. Data from vehicle design standards indicates that the cowl firewall must meet stringent safety and durability requirements to enhance occupant protection during collisions and environmental exposure. Modern manufacturing techniques use high-strength steel or reinforced composites to optimize weight and rigidity in the cowl area. Entities such as automobile manufacturers and component suppliers prioritize cowl firewall design to improve overall vehicle performance and ensure compliance with regulatory emissions and safety standards.

Table of Comparison

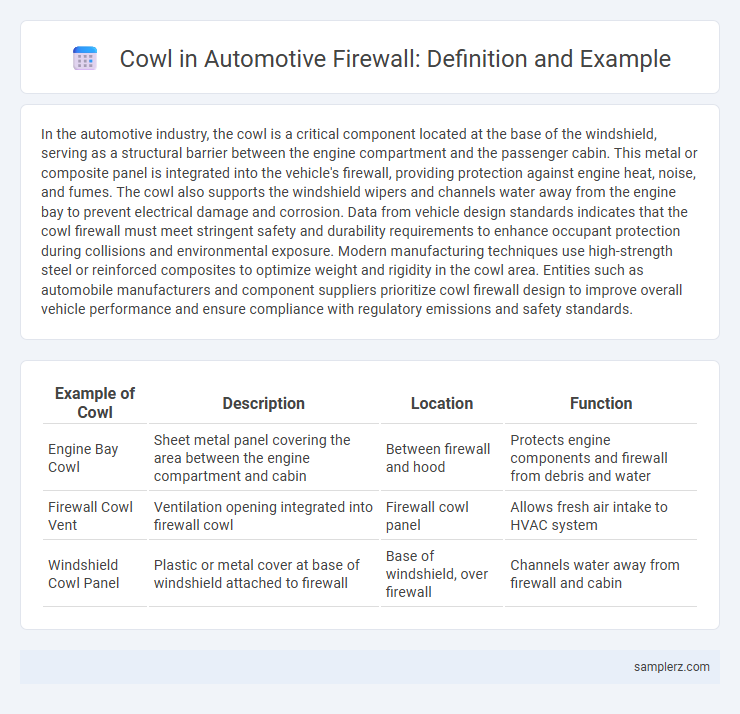

| Example of Cowl | Description | Location | Function |

|---|---|---|---|

| Engine Bay Cowl | Sheet metal panel covering the area between the engine compartment and cabin | Between firewall and hood | Protects engine components and firewall from debris and water |

| Firewall Cowl Vent | Ventilation opening integrated into firewall cowl | Firewall cowl panel | Allows fresh air intake to HVAC system |

| Windshield Cowl Panel | Plastic or metal cover at base of windshield attached to firewall | Base of windshield, over firewall | Channels water away from firewall and cabin |

Definition of Cowl and Firewall in Automotive Engineering

In automotive engineering, the cowl refers to the structural panel located between the hood and the windshield, serving as a mounting point for the windshield and providing ventilation openings. The firewall is a critical barrier positioned between the engine compartment and the passenger cabin, designed to prevent heat, noise, and fire from entering the interior. Together, the cowl and firewall enhance vehicle safety and cabin comfort by protecting occupants from engine-related hazards.

Key Functions of the Cowl Panel in Vehicle Design

The cowl panel in vehicle design serves as a critical structural component that supports the windshield and provides a mounting point for wiper assemblies. It acts as a barrier between the engine compartment and passenger cabin, enhancing thermal insulation and noise reduction. Furthermore, the cowl panel contributes to vehicle aerodynamics by directing airflow and preventing water ingress into the firewall area.

How the Cowl Integrates with the Firewall Structure

The cowl in automotive design seamlessly integrates with the firewall structure by serving as a reinforced panel that connects the vehicle's exterior body to the engine compartment. This integration provides structural rigidity, enhancing occupant safety and improving the vehicle's aerodynamic flow. By forming a continuous barrier, the cowl also helps prevent the ingress of water, debris, and noise from the engine bay into the passenger cabin.

Common Materials Used for Cowls and Firewalls

Cowl panels and firewalls in automotive design are typically constructed from steel, aluminum, or composite materials to provide strength, durability, and corrosion resistance. Steel offers high structural integrity, while aluminum reduces vehicle weight and improves fuel efficiency. Composite materials, such as fiberglass-reinforced plastics, enhance thermal insulation and noise reduction within the engine compartment.

Typical Locations of the Cowl in Modern Vehicles

The cowl in modern vehicles is typically located at the base of the windshield, forming a crucial barrier between the engine compartment and the passenger cabin. It serves to house windshield wipers and facilitates air intake for the HVAC system, ensuring optimal airflow and protection from water ingress. Positioned on the firewall, the cowl integrates with structural components to enhance vehicle rigidity and safety.

Examples of Cowl Features in Passenger Cars

Cowl features in passenger cars commonly include integrated windshield wiper mounts, air intake vents for cabin ventilation, and reinforced structural elements for enhanced crash protection. These cowls often incorporate drainage channels to prevent water ingress into the firewall and engine compartment. Advanced designs may also integrate sound-deadening materials to reduce engine noise transmitted into the cabin.

Role of the Cowl in HVAC System Placement

The cowl in the firewall serves as a critical component in the HVAC system placement, providing a sealed interface that prevents engine heat and fumes from entering the vehicle's cabin while allowing fresh air intake. Positioned between the engine compartment and passenger area, the cowl directs airflow into the HVAC system, enhancing ventilation efficiency and occupant comfort. Proper cowl design improves air filtration and reduces noise, contributing significantly to thermal management and air quality inside the vehicle.

Cowl Panel Innovations in Recent Car Models

Recent car models feature advanced cowl panel designs that enhance structural integrity and improve aerodynamics, contributing to quieter cabins and better windshield wiper performance. Innovations include integrated air intake systems within the cowl panel that optimize engine cooling and cabin ventilation while reducing drag. Manufacturers are also using lightweight composite materials for cowl panels, balancing durability with fuel efficiency in automotive design.

Cowl and Firewall Maintenance Best Practices

Regular inspection of the cowl and firewall area is essential to prevent debris accumulation and corrosion that can compromise vehicle safety. Cleaning the cowl vent and ensuring proper sealing of the firewall reduces moisture ingress and protects critical electrical components from damage. Implementing routine maintenance checks, including rust treatment and seal replacement, extends the lifespan of these structural elements and maintains optimal engine compartment conditions.

The Impact of Cowl Design on Vehicle Safety

The cowl design in the firewall area significantly enhances vehicle safety by providing structural integrity and improving crash energy absorption. Optimized cowl geometry reduces cabin intrusion during frontal collisions, protecting occupants from injury. Advanced materials used in cowl construction also contribute to improved crash performance and durability in modern automotive designs.

example of cowl in firewall Infographic

samplerz.com

samplerz.com