A trunnion in automotive suspension refers to a pivoting support or mounting point that allows controlled movement of suspension components, typically found in solid axle systems. Trunnions are essential for enabling articulation while maintaining alignment and stability of the axle during driving. This component often connects the axle housing to control arms or suspension links, facilitating smooth motion and load transfer. In heavy-duty trucks and off-road vehicles, trunnion suspensions provide enhanced durability and flexibility compared to conventional setups. The data shows trunnion suspensions improve ride quality and handling by allowing axle movement without compromising vehicle control. Engineers focus on materials and precise machining of the trunnion to withstand stress and extend service life under extreme conditions.

Table of Comparison

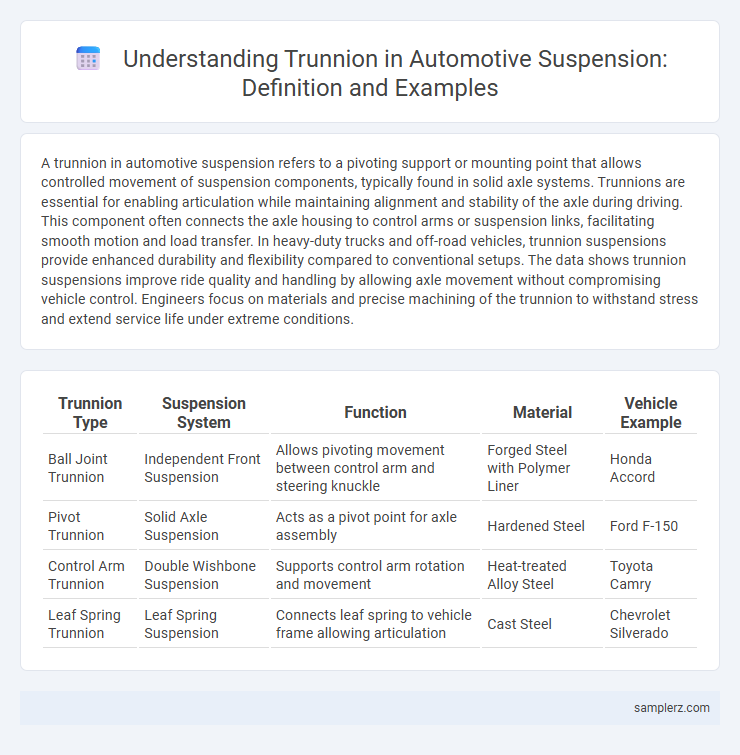

| Trunnion Type | Suspension System | Function | Material | Vehicle Example |

|---|---|---|---|---|

| Ball Joint Trunnion | Independent Front Suspension | Allows pivoting movement between control arm and steering knuckle | Forged Steel with Polymer Liner | Honda Accord |

| Pivot Trunnion | Solid Axle Suspension | Acts as a pivot point for axle assembly | Hardened Steel | Ford F-150 |

| Control Arm Trunnion | Double Wishbone Suspension | Supports control arm rotation and movement | Heat-treated Alloy Steel | Toyota Camry |

| Leaf Spring Trunnion | Leaf Spring Suspension | Connects leaf spring to vehicle frame allowing articulation | Cast Steel | Chevrolet Silverado |

Understanding Trunnions in Automotive Suspension Systems

Trunnions in automotive suspension systems serve as pivotal mounting points allowing controlled movement between suspension components, enhancing vehicle stability and ride comfort. These cylindrical bearings connect control arms or steering knuckles to the chassis, facilitating smooth articulation and absorbing road shocks effectively. High-quality trunnions contribute to improved handling precision, reduced wear on suspension parts, and extended vehicle lifespan.

The Role of Trunnions in Vehicle Suspension

Trunnions act as pivotal connectors in vehicle suspension systems, allowing controlled movement between suspension arms and chassis components for enhanced stability and ride comfort. They bear significant loads while enabling smooth articulation of the suspension, crucial for absorbing road shocks and maintaining tire contact with the ground. High-quality trunnions made from durable materials like forged steel improve suspension durability and handling performance in automotive applications.

Key Types of Trunnion Designs Used in Cars

Key types of trunnion designs used in automotive suspension systems include ball-and-socket, pivot pin, and cylindrical trunnions. Ball-and-socket trunnions allow multi-directional movement, providing enhanced steering flexibility and durability in front suspension assemblies. Pivot pin trunnions are commonly found in leaf spring suspensions, offering controlled articulation and load distribution for improved vehicle stability.

Trunnion Suspension Example: Classic Double Wishbone Setup

The trunnion suspension in a classic double wishbone setup serves as a pivotal mounting point allowing controlled rotational movement of the lower control arm, enhancing wheel articulation and stability. This design improves handling precision and reduces unwanted chassis flex, ideal for performance vehicles and off-road applications. Key components include the trunnion pin, lower control arm, and reinforced wishbones engineered to withstand dynamic loads during cornering and uneven terrain.

Trunnion Applications in Heavy-Duty Truck Suspensions

Trunnions in heavy-duty truck suspensions serve as pivotal components that connect the axle to the suspension system, enabling controlled articulation and load distribution. These robust pivot points optimize ride stability and durability under extreme hauling conditions by accommodating vertical and lateral movements. Their engineering ensures enhanced suspension performance, reducing wear on other components and improving overall vehicle safety and handling.

How Trunnions Improve Ride Comfort and Handling

Trunnions in automotive suspension systems serve as pivotal connection points that allow controlled rotational movement between suspension components, enhancing vehicle stability. By absorbing and distributing dynamic loads during cornering and uneven road conditions, trunnions reduce vibrations and shocks transferred to the cabin, significantly improving ride comfort. Their precise articulation improves handling responsiveness, enabling smoother steering inputs and better traction control on diverse terrains.

Common Materials for Automotive Trunnion Construction

Automotive trunnions in suspension systems are commonly constructed from high-strength steel alloys such as 4140 chrome-molybdenum steel, known for its excellent fatigue resistance and durability under dynamic loads. Cast iron and ductile iron variants are also used due to their cost-effectiveness and good wear resistance, especially in heavy-duty applications. Advanced materials like forged aluminum alloys offer lightweight alternatives while maintaining sufficient structural integrity for performance vehicles.

Maintenance Tips for Suspension Trunnions

Regularly inspect suspension trunnions for signs of wear, corrosion, or damage to ensure optimal vehicle stability and handling. Apply high-quality grease to trunnion joints during routine maintenance to reduce friction and prevent premature wear. Replace worn or damaged trunnions promptly to maintain suspension integrity and enhance overall driving safety.

Comparing Trunnion Suspension to Ball Joint Systems

Trunnion suspension systems provide enhanced durability and load-bearing capacity compared to traditional ball joint systems, making them ideal for heavy-duty automotive applications. Trunnions typically offer reduced maintenance due to fewer moving parts and a more robust design, which minimizes wear and improves vehicle stability over rough terrain. Ball joint systems, while offering greater flexibility and smoother steering response, often require more frequent replacement and are less suited for high-stress environments.

Future Trends for Trunnion Technology in Automotive Suspension

Future trends in trunnion technology for automotive suspension emphasize the integration of lightweight composite materials and advanced corrosion-resistant alloys to enhance durability and reduce vehicle weight. Smart trunnions embedded with sensors will enable real-time monitoring of suspension performance, improving safety and predictive maintenance. Innovations in additive manufacturing will allow for complex geometries, optimizing load distribution and minimizing wear in next-generation suspension systems.

example of trunnion in suspension Infographic

samplerz.com

samplerz.com