In automotive engineering, a yoke in a driveshaft serves as a critical mechanical component that connects the driveshaft to other parts of the drivetrain. This yoke allows for the transmission of torque and rotational force between components such as the transmission and the differential. The design of the yoke ensures flexibility and alignment, accommodating angular movement and reducing stress on the driveshaft assembly. Manufacturers commonly use steel or aluminum alloys to produce yokes due to their strength and durability. The yoke typically features splines or a flange that fits securely onto the driveshaft or universal joint, maintaining a stable yet flexible connection. Proper maintenance and inspection of the yoke are essential to prevent driveline vibrations and ensure optimal vehicle performance.

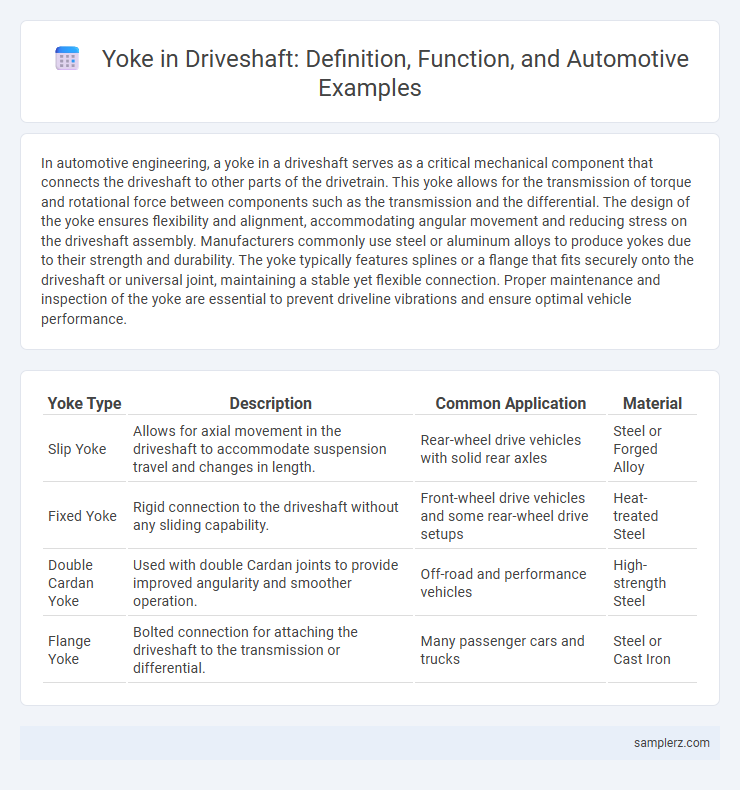

Table of Comparison

| Yoke Type | Description | Common Application | Material |

|---|---|---|---|

| Slip Yoke | Allows for axial movement in the driveshaft to accommodate suspension travel and changes in length. | Rear-wheel drive vehicles with solid rear axles | Steel or Forged Alloy |

| Fixed Yoke | Rigid connection to the driveshaft without any sliding capability. | Front-wheel drive vehicles and some rear-wheel drive setups | Heat-treated Steel |

| Double Cardan Yoke | Used with double Cardan joints to provide improved angularity and smoother operation. | Off-road and performance vehicles | High-strength Steel |

| Flange Yoke | Bolted connection for attaching the driveshaft to the transmission or differential. | Many passenger cars and trucks | Steel or Cast Iron |

Understanding the Role of a Yoke in a Driveshaft

A yoke in a driveshaft serves as a critical mechanical component that connects the driveshaft to the transmission or differential, facilitating the transfer of rotational motion. It allows for slight angular misalignments between connected parts, enhancing the drivetrain's flexibility and durability. High-quality yokes are typically made from alloy steel for strength and resistance to wear, ensuring optimal performance in automotive drivetrains.

Types of Yokes Used in Automotive Driveshafts

Automotive driveshafts utilize several types of yokes, including slip yokes, fixed yokes, and flange yokes, each serving distinct functions in torque transfer and flexibility. Slip yokes accommodate length changes in the driveshaft during suspension movement, while fixed yokes maintain a rigid connection between the driveshaft and the transmission or differential. Flange yokes provide secure attachment points, commonly used in heavy-duty and performance vehicles to ensure durability and precise alignment.

Key Components of a Driveshaft Yoke Assembly

Key components of a driveshaft yoke assembly include the yoke itself, typically forged from steel or aluminum for high strength and durability, which connects to the universal joint allowing rotational movement. The universal joint (U-joint) enables flexibility and compensates for angle changes between the driveshaft and the differential or transmission. Precision bearings and seals within the yoke assembly ensure smooth operation and protect internal components from contaminants, enhancing the drivetrain's overall performance and reliability.

How a Yoke Connects Driveshaft to Transmission

A yoke connects the driveshaft to the transmission by securely linking the splined end of the driveshaft to the transmission output shaft, allowing for torque transfer while accommodating angular movement. It typically features a U-joint (universal joint) that enables the driveshaft to flex and adjust to variations in alignment and suspension travel. This connection ensures smooth power delivery from the engine to the wheels, maintaining drivetrain flexibility and reducing vibration.

Common Materials for Driveshaft Yokes

Driveshaft yokes are commonly fabricated from high-strength steel alloys such as SAE 1045 and chromoly steel, known for their durability and resistance to torsional stress. Aluminum alloys and composite materials are increasingly used in performance vehicles to reduce weight while maintaining structural integrity. Heat-treated and precision-machined components ensure optimal performance and longevity under varying automotive load conditions.

Signs of a Failing Driveshaft Yoke

A failing driveshaft yoke often exhibits symptoms such as excessive vibration during acceleration, clunking noises when shifting gears, and visible wear or rust on the yoke itself. These signs indicate potential issues with the universal joint or misalignment, which can lead to drivetrain imbalance and reduced vehicle performance. Early detection through routine inspections can prevent costly repairs and ensure safe driving conditions.

Step-by-Step Example: U-Joint Yoke Installation

To install a U-joint yoke on a driveshaft, first align the yoke with the driveshaft splines ensuring a proper fit. Press the yoke into place using a hydraulic press or a bench vise, checking that the needle bearings remain correctly positioned within the U-joint caps. Secure the yoke with retaining clips or snap rings, verifying smooth rotational movement without any binding or excessive play.

Benefits of Precision-Balanced Yokes in Driveshafts

Precision-balanced yokes in driveshafts enhance rotational stability, reducing vibrations and minimizing wear on drivetrain components. This improvement leads to smoother torque transfer and extended service life, supporting optimal vehicle performance and fuel efficiency. Manufacturers benefit from reduced maintenance costs and increased reliability by integrating precision-balanced yokes into automotive driveshaft assemblies.

OEM vs Aftermarket Driveshaft Yoke Examples

OEM driveshaft yokes are engineered to meet precise manufacturer specifications, ensuring optimal fitment, durability, and performance in automotive drivetrains. Aftermarket driveshaft yokes offer a wider variety of materials and designs, often providing enhanced strength or customization options but may vary in quality and compatibility. Comparing OEM versus aftermarket yokes highlights differences in warranty coverage, corrosion resistance, and adherence to torque ratings critical for vehicles' driveline reliability.

Maintenance Tips for Driveshaft Yoke Longevity

Regularly inspect the driveshaft yoke for signs of wear, corrosion, or cracks to ensure optimal performance and prevent failure. Lubricate the yoke's universal joint with high-quality grease at recommended intervals, maintaining smooth rotation and reducing friction. Proper alignment during installation minimizes stress on the yoke, extending its lifespan and enhancing overall driveshaft durability.

example of yoke in driveshaft Infographic

samplerz.com

samplerz.com