A pentroof combustion chamber in automotive engines features a design where the cylinder head has a slanted roof shape resembling a pentagon. This configuration allows for the placement of four valves per cylinder, improving airflow and combustion efficiency. Commonly used in high-performance and modern multi-valve engines, the pentroof chamber enhances power output and reduces emissions. The pentroof design optimizes the flame front propagation due to its compact and centrally located spark plug arrangement. Data from various engine tests show increased volumetric efficiency and better fuel atomization in pentroof chambers compared to traditional flat or hemispherical designs. Automotive manufacturers frequently adopt this chamber type to balance performance, fuel economy, and stringent emission standards.

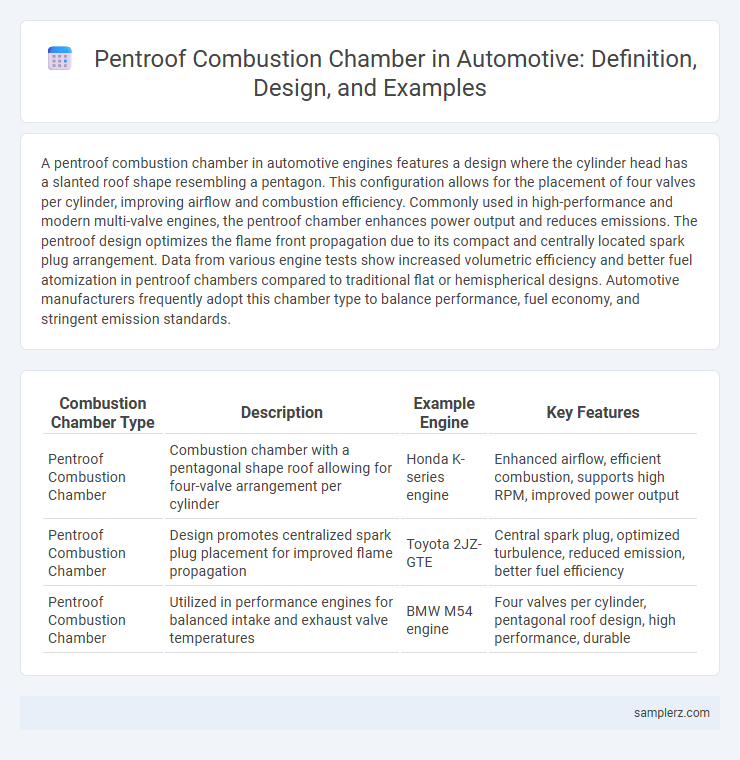

Table of Comparison

| Combustion Chamber Type | Description | Example Engine | Key Features |

|---|---|---|---|

| Pentroof Combustion Chamber | Combustion chamber with a pentagonal shape roof allowing for four-valve arrangement per cylinder | Honda K-series engine | Enhanced airflow, efficient combustion, supports high RPM, improved power output |

| Pentroof Combustion Chamber | Design promotes centralized spark plug placement for improved flame propagation | Toyota 2JZ-GTE | Central spark plug, optimized turbulence, reduced emission, better fuel efficiency |

| Pentroof Combustion Chamber | Utilized in performance engines for balanced intake and exhaust valve temperatures | BMW M54 engine | Four valves per cylinder, pentagonal roof design, high performance, durable |

Introduction to Pentroof Combustion Chambers

Pentroof combustion chambers feature a hemispherical design with two or more valves arranged at an angle, optimizing airflow and combustion efficiency. This configuration allows for better fuel-air mixture turbulence and faster flame propagation, improving power output and reducing emissions in automotive engines. Pentroof chambers are widely used in high-performance engines due to their superior volumetric efficiency and thermal characteristics.

Historical Development of Pentroof Designs

Pentroof combustion chambers evolved significantly since their introduction in the early 20th century, driven by the need for improved airflow and more efficient fuel-air mixing. Early pentroof designs featured simple, sloped surfaces to accommodate dual overhead camshafts and four valves per cylinder, enhancing power output and reducing emissions. Advancements in materials and computer-aided design further refined pentroof geometry, optimizing combustion efficiency and enabling higher engine speeds in modern automotive engines.

Key Features of Pentroof Combustion Chambers

Pentroof combustion chambers feature a compact, pentagonal-shaped design that optimizes airflow and fuel atomization, enhancing the efficiency of the combustion process. This chamber type is characterized by centrally located spark plugs and multiple valves angled to improve air-fuel mixture distribution, contributing to higher power output and reduced emissions. The design supports higher compression ratios and promotes rapid, complete combustion, making it ideal for modern high-performance gasoline engines.

Advantages of Pentroof in Engine Performance

Pentroof combustion chambers optimize air-fuel mixture swirl, enhancing fuel atomization and combustion efficiency in automotive engines. This design improves volumetric efficiency and supports higher compression ratios, leading to increased power output and reduced emissions. The symmetrical layout facilitates better spark plug placement, promoting faster and more complete combustion.

Example: Pentroof Chamber in Modern Inline-4 Engines

Pentroof chambers in modern inline-4 engines optimize combustion efficiency by featuring a dome-shaped piston crown and four-valve configuration, enhancing airflow and fuel mixture. This design improves volumetric efficiency and promotes faster flame propagation, resulting in increased power output and reduced emissions. Manufacturers like Toyota and Honda commonly utilize pentroof chambers to achieve higher performance and fuel economy in their compact engines.

Pentroof Design in High-Performance Sports Cars

Pentroof design in high-performance sports cars enhances combustion efficiency by optimizing the shape of the combustion chamber to achieve better air-fuel mixture and faster flame propagation. This design features a four-valve-per-cylinder layout angled towards the center, increasing volumetric efficiency and enabling higher engine RPMs. Manufacturers like Ferrari and Porsche utilize pentroof combustion chambers to maximize power output and reduce emissions in their sports car engines.

Impact on Fuel Efficiency and Emissions

A pentroof combustion chamber design improves fuel efficiency by promoting better air-fuel mixture swirl and more complete combustion, reducing unburned hydrocarbons. This design enhances flame propagation speed, leading to lower fuel consumption and decreased carbon monoxide emissions. The optimized combustion process in pentroof chambers also results in reduced nitrogen oxide formation, contributing to cleaner exhaust gases.

Comparison: Pentroof vs. Hemispherical Chambers

Pentroof combustion chambers feature a flat, angled roof with multiple valves per cylinder, optimizing airflow and fuel mixture for improved combustion efficiency compared to hemispherical chambers. Hemispherical chambers, with their dome-shaped design, promote better flame propagation but typically support fewer valves, limiting valve area and airflow. The pentroof design's enhanced valve arrangement often leads to higher power output and reduced emissions in modern automotive engines.

Notable Vehicles Utilizing Pentroof Technology

Notable vehicles utilizing pentroof combustion chambers include the Honda Civic and Toyota Camry, which benefit from enhanced air-fuel mixing and efficient combustion. The pentroof design improves volumetric efficiency and reduces emissions by allowing for optimal spark plug placement and flame propagation. Many high-performance and fuel-efficient engines incorporate pentroof chambers to balance power output with environmental standards.

Future Trends in Pentroof Combustion Chamber Design

Pentroof combustion chamber design is evolving with advanced technologies like laser-etched surface texturing and optimized swirl generation to enhance air-fuel mixing and combustion efficiency. Integration of variable valve timing and direct fuel injection systems further refines combustion control, reducing emissions and improving fuel economy. Future trends emphasize lightweight materials and enhanced thermal management to support higher compression ratios and enable cleaner, more efficient internal combustion engines.

example of pentroof in combustion Infographic

samplerz.com

samplerz.com