The MacPherson strut is a common front suspension system widely used in modern automotive design due to its simplicity and cost-effectiveness. It combines a shock absorber and coil spring into a single compact unit, which supports the vehicle's weight while allowing the front wheels to move independently. This design improves ride comfort and handling by reducing the number of components and simplifying the steering mechanism. In a typical application, the MacPherson strut is mounted between the wheel hub and the vehicle's chassis, acting as both a suspension link and a structural component. It allows for efficient space utilization under the engine bay, making it ideal for front-wheel-drive vehicles. Data shows that this suspension type contributes to lower production costs and easier maintenance while maintaining adequate performance for daily driving conditions.

Table of Comparison

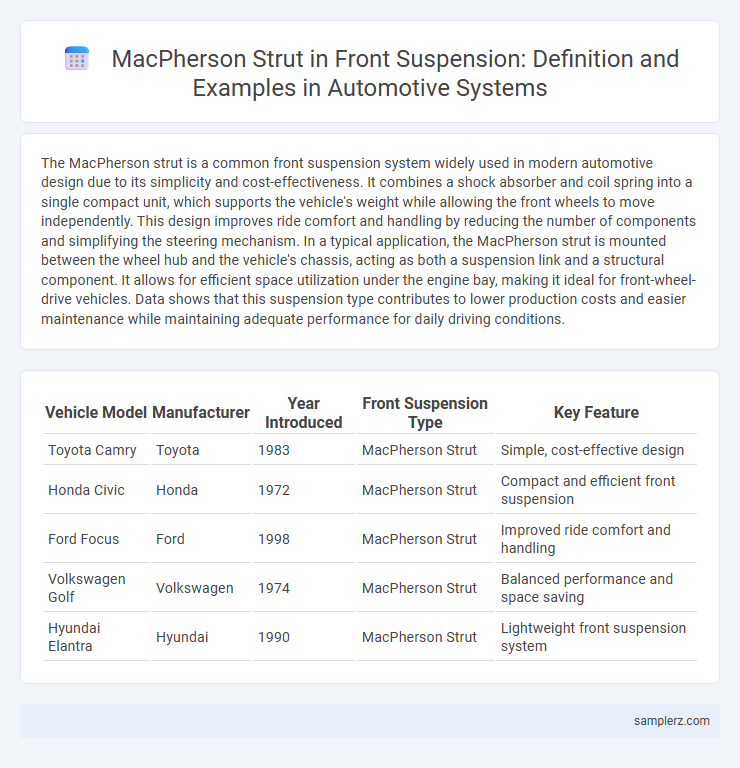

| Vehicle Model | Manufacturer | Year Introduced | Front Suspension Type | Key Feature |

|---|---|---|---|---|

| Toyota Camry | Toyota | 1983 | MacPherson Strut | Simple, cost-effective design |

| Honda Civic | Honda | 1972 | MacPherson Strut | Compact and efficient front suspension |

| Ford Focus | Ford | 1998 | MacPherson Strut | Improved ride comfort and handling |

| Volkswagen Golf | Volkswagen | 1974 | MacPherson Strut | Balanced performance and space saving |

| Hyundai Elantra | Hyundai | 1990 | MacPherson Strut | Lightweight front suspension system |

Introduction to MacPherson Strut Front Suspension

MacPherson strut front suspension is widely utilized in compact and mid-sized vehicles due to its simplicity and space efficiency. This design combines a shock absorber and coil spring into a single, compact unit that supports the vehicle's weight while allowing smooth wheel articulation. Its cost-effectiveness and lightweight construction contribute to improved fuel efficiency and handling performance in various automotive models.

Key Components of the MacPherson Strut System

The MacPherson strut system in front suspension primarily consists of a coil spring wrapped around a shock absorber, a steering knuckle, and a lower control arm. The coil spring absorbs road shocks while the shock absorber dampens vibrations, providing stability and comfort. The steering knuckle connects the strut assembly to the wheel hub, allowing for smooth steering and wheel alignment.

Historical Development of the MacPherson Strut

The MacPherson strut, introduced by Earle S. MacPherson in the 1940s, revolutionized front suspension design with its compact and cost-effective structure, initially implemented in the 1950 Ford Vedette. This innovation integrated the shock absorber and coil spring into a single unit, enabling improved ride comfort and simplified assembly in mass-produced vehicles. The widespread adoption of MacPherson struts by manufacturers like Ford and Volkswagen throughout the 1950s and 1960s marked a significant shift toward more efficient suspension systems in automotive engineering.

Working Principle of a MacPherson Strut

The MacPherson strut in front suspension integrates a shock absorber and a coil spring into a single unit, providing damping and spring support. It functions by allowing vertical movement of the wheel while maintaining the alignment of the wheel hub through the steering knuckle connected to the strut assembly. This design optimizes space and weight, improving handling and ride comfort in many compact and mid-size vehicles.

Advantages of MacPherson Strut in Front Suspension

The MacPherson strut in front suspension offers a compact design that reduces overall vehicle weight, improving fuel efficiency and handling responsiveness. Its simple construction lowers manufacturing costs while providing effective damping and structural support for better ride comfort. The strut's integration with the steering system enhances precise wheel alignment and stability during cornering.

Limitations of MacPherson Strut Design

The MacPherson strut design, widely used in front suspension systems, faces limitations such as reduced camber control during aggressive cornering, which can affect tire contact and handling precision. Its single-point mounting and compact layout limit suspension travel and adjustability, often resulting in compromised ride comfort on uneven terrain. Additionally, the structural demands on the strut bearing and lower control arm increase wear and complicate maintenance compared to multi-link suspension designs.

Real-World Car Models Using MacPherson Strut

The Toyota Camry and Honda Civic are prominent examples of real-world car models utilizing MacPherson strut front suspension for its compact design and effective handling. The Volkswagen Golf and Ford Focus also employ this suspension type, offering a blend of comfort and responsive steering. This widespread adoption in compact and midsize vehicles highlights the MacPherson strut's efficiency in balancing cost, space, and performance.

Comparison: MacPherson Strut vs. Double Wishbone

The MacPherson strut front suspension features a single lower control arm combined with a shock absorber and coil spring in one unit, offering a compact design ideal for front-wheel-drive vehicles with limited space. In contrast, the double wishbone suspension uses two separate control arms, providing greater camber control and superior handling performance, especially on uneven road surfaces. While the MacPherson strut is cost-effective and simpler to manufacture, the double wishbone system excels in delivering enhanced stability and improved tire contact during cornering.

Maintenance Tips for MacPherson Strut Suspension

Regularly inspect the MacPherson strut for signs of wear such as leaking fluid, damaged mounts, or unusual noises to ensure optimal suspension performance. Replace worn strut mounts and check the coil springs for corrosion to prevent handling issues and uneven tire wear. Proper lubrication and timely alignment adjustments extend the lifespan of MacPherson strut suspensions while maintaining vehicle stability.

Future Trends in Front Suspension Technologies

The MacPherson strut continues to evolve with the integration of electric and adaptive damping technologies, enhancing ride comfort and vehicle handling precision in modern automotive designs. Advances in lightweight materials such as aluminum and composites optimize the strut's structural efficiency, contributing to overall weight reduction and improved fuel economy. Future front suspension systems increasingly incorporate sensors and active controls to dynamically adjust suspension characteristics in real-time, aligning with trends toward autonomous driving and enhanced safety features.

example of MacPherson strut in front suspension Infographic

samplerz.com

samplerz.com