In the automotive industry, a waffle pattern in the chassis refers to a grid-like structure incorporated into the metal framework. This design technique enhances rigidity and strength while minimizing weight, crucial for vehicle performance and fuel efficiency. Manufacturers often use waffle patterns in floor pans and underbody panels to provide structural integrity without adding excessive mass. The waffle design achieves a balance between stiffness and flexibility, allowing the chassis to absorb impacts and improve crash safety. Engineers utilize advanced stamping and hydroforming processes to create these intricate patterns in high-strength steel or aluminum alloys. Data shows that vehicles with waffle-patterned chassis components exhibit improved torsional stiffness and reduced noise, vibration, and harshness (NVH) levels.

Table of Comparison

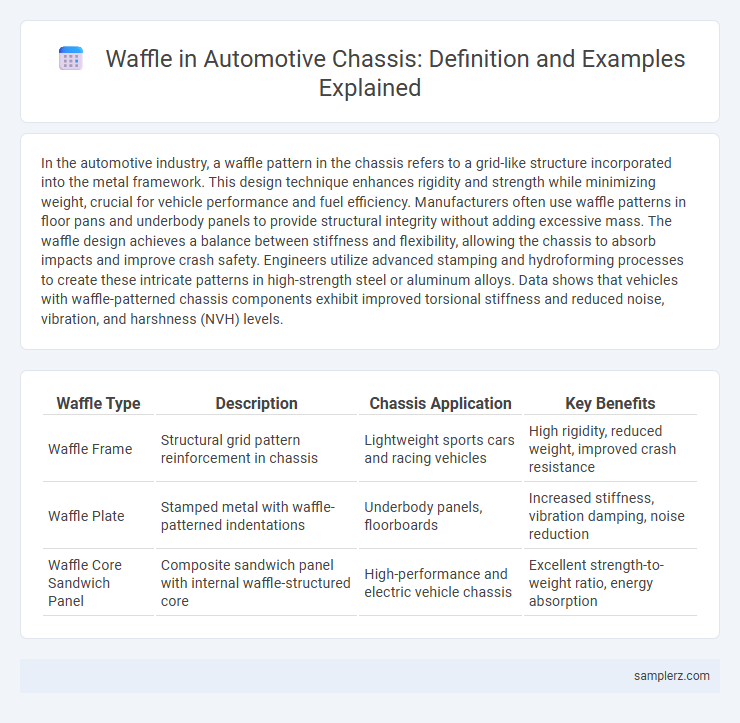

| Waffle Type | Description | Chassis Application | Key Benefits |

|---|---|---|---|

| Waffle Frame | Structural grid pattern reinforcement in chassis | Lightweight sports cars and racing vehicles | High rigidity, reduced weight, improved crash resistance |

| Waffle Plate | Stamped metal with waffle-patterned indentations | Underbody panels, floorboards | Increased stiffness, vibration damping, noise reduction |

| Waffle Core Sandwich Panel | Composite sandwich panel with internal waffle-structured core | High-performance and electric vehicle chassis | Excellent strength-to-weight ratio, energy absorption |

Introduction to Waffle Structures in Automotive Chassis

Waffle structures in automotive chassis use grid-like patterns to enhance rigidity while minimizing weight, contributing to improved vehicle performance and fuel efficiency. These geometrically optimized formations distribute stress evenly, reducing the risk of deformation under dynamic loads. Incorporating waffle designs allows manufacturers to achieve high strength-to-weight ratios essential for modern lightweight vehicle construction.

Key Benefits of Waffle Design in Chassis Engineering

Waffle design in chassis engineering enhances structural rigidity while minimizing weight, leading to improved vehicle handling and fuel efficiency. The grid-like pattern distributes stress uniformly, increasing durability and resistance to deformation under dynamic loads. This innovative approach optimizes material usage, reducing manufacturing costs and contributing to overall vehicle performance.

Historical Evolution of Waffle Patterns in Automotive Frames

Waffle patterns in automotive chassis originated in the early 20th century as engineers sought to enhance structural rigidity while minimizing weight. These grid-like reinforcements evolved through the introduction of stamped steel and hydroforming techniques, significantly improving crash safety and vehicle handling. Modern automotive frames utilize advanced waffle patterns optimized by computer-aided design to balance strength, durability, and manufacturing efficiency.

Comparing Waffle Chassis to Traditional Ladder Frames

Waffle chassis designs offer enhanced rigidity and weight distribution compared to traditional ladder frames, making them ideal for high-performance and off-road vehicles. The grid-like pattern of a waffle chassis increases torsional stiffness while reducing overall weight, improving vehicle handling and fuel efficiency. Traditional ladder frames, with their straightforward beam layout, provide durability but lack the structural optimization found in waffle chassis, leading to heavier builds and less precise handling.

Notable Car Models Featuring Waffle Chassis Examples

The Lamborghini Countach features a pioneering waffle chassis design that improved rigidity while reducing weight, setting a benchmark in supercar engineering. The McLaren F1 utilized a carbon fiber waffle monocoque chassis, delivering exceptional strength and safety for high-performance driving. The BMW M3 E30 incorporated waffle-style reinforcements within its chassis structure, enhancing torsional stiffness and handling precision.

Lightweighting Approaches: The Role of Waffle Construction

Waffle construction in automotive chassis design leverages a grid-like pattern to enhance structural rigidity while significantly reducing weight, contributing to lightweighting efforts that improve fuel efficiency and vehicle performance. This approach optimizes material distribution, using fewer resources without compromising strength or safety, making it ideal for electric and hybrid vehicles aiming to maximize battery range. Advanced manufacturing techniques, such as additive manufacturing and high-strength aluminum alloys, further enable the practical implementation of waffle structures in modern chassis systems.

How Waffle Structure Improves Crash Safety

A waffle structure in automotive chassis design enhances crash safety by distributing impact forces more evenly across the frame, reducing localized stress and deformation. This geometric pattern increases rigidity and energy absorption capacity, allowing the chassis to better maintain occupant compartment integrity during collisions. By optimizing load paths, waffle structures help minimize intrusion and protect passengers in high-impact scenarios.

Manufacturing Techniques for Waffle Chassis Panels

Manufacturing techniques for waffle chassis panels in automotive applications primarily involve stamping and hydroforming processes to create the unique grid-like pattern that enhances structural rigidity and reduces weight. Advanced laser cutting and CNC machining are employed to achieve precise dimensions and intricate waffle geometries, optimizing load distribution across the chassis. Utilizing high-strength steels or aluminum alloys in these techniques improves the durability and crashworthiness of the waffle chassis panels, contributing to overall vehicle performance and safety.

Material Innovation in Waffle Chassis Application

Advanced material innovation in waffle chassis applications utilizes high-strength aluminum alloys and carbon fiber composites to enhance structural rigidity while minimizing weight. Incorporating these materials into the waffle pattern significantly improves impact resistance and energy absorption during collisions. This approach optimizes vehicle performance by reducing chassis flex and increasing overall durability.

Future Trends in Waffle Chassis Design for Automotives

Future trends in waffle chassis design for automotives emphasize lightweight materials such as carbon fiber composites to enhance structural rigidity while reducing overall vehicle weight. Advanced manufacturing techniques like 3D printing enable intricate waffle patterns that optimize energy absorption and improve crash safety. Integration of smart sensors within the waffle chassis framework allows real-time monitoring of stress and strain, facilitating predictive maintenance and extending chassis lifespan.

example of waffle in chassis Infographic

samplerz.com

samplerz.com