A cutout in an automotive exhaust system refers to a valve or flap installed within the exhaust pipe that allows the driver to bypass the muffler. This setup modifies the exhaust flow, leading to increased engine performance and a louder exhaust sound when the cutout is open. Cutouts are often used in performance vehicles to achieve a balance between noise levels for daily driving and maximum power output during racing or spirited driving. The installation of a cutout involves integrating it into the exhaust piping before the muffler or catalytic converter. These devices can be manually operated via a cable or electronically controlled using a switch inside the vehicle cabin. Data from performance tests show that exhaust cutouts can improve horsepower by reducing back pressure, although emissions compliance should be considered depending on local regulations.

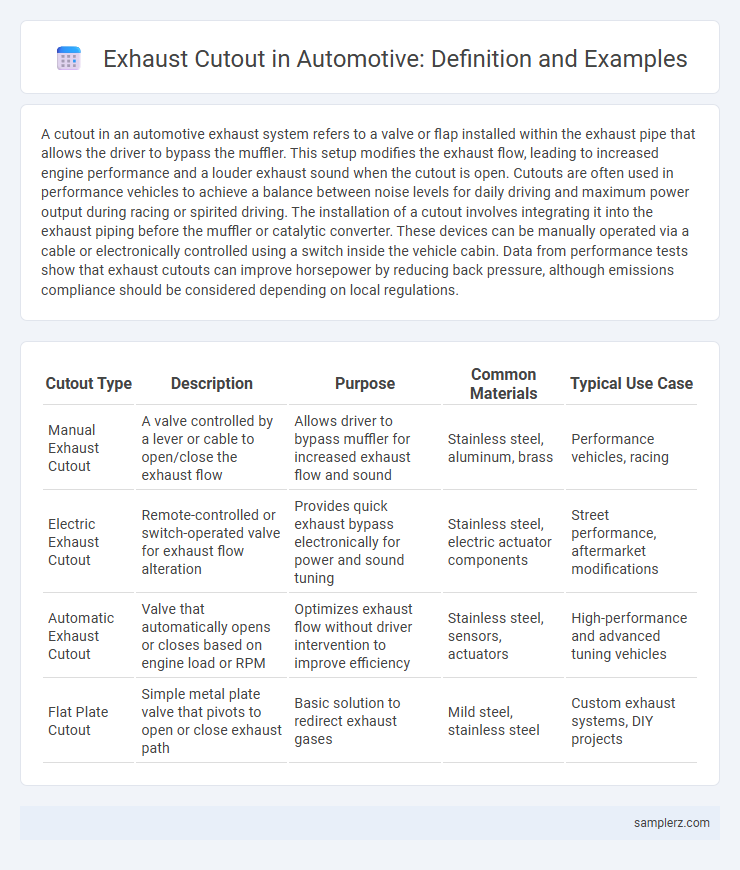

Table of Comparison

| Cutout Type | Description | Purpose | Common Materials | Typical Use Case |

|---|---|---|---|---|

| Manual Exhaust Cutout | A valve controlled by a lever or cable to open/close the exhaust flow | Allows driver to bypass muffler for increased exhaust flow and sound | Stainless steel, aluminum, brass | Performance vehicles, racing |

| Electric Exhaust Cutout | Remote-controlled or switch-operated valve for exhaust flow alteration | Provides quick exhaust bypass electronically for power and sound tuning | Stainless steel, electric actuator components | Street performance, aftermarket modifications |

| Automatic Exhaust Cutout | Valve that automatically opens or closes based on engine load or RPM | Optimizes exhaust flow without driver intervention to improve efficiency | Stainless steel, sensors, actuators | High-performance and advanced tuning vehicles |

| Flat Plate Cutout | Simple metal plate valve that pivots to open or close exhaust path | Basic solution to redirect exhaust gases | Mild steel, stainless steel | Custom exhaust systems, DIY projects |

Introduction to Exhaust Cutouts in Automotive Systems

Exhaust cutouts are devices installed in automotive exhaust systems that allow drivers to bypass portions of the exhaust piping for increased flow and sound control. Typically fabricated from stainless steel or aluminum, these cutouts can be manually or electronically operated to redirect exhaust gases, enhancing engine performance and producing a more aggressive exhaust note. Popular in performance and racing vehicles, exhaust cutouts provide a customizable balance between exhaust efficiency and noise regulations.

Types of Exhaust Cutouts: Manual vs. Electric

Exhaust cutouts come in two primary types: manual and electric, each offering distinct control over exhaust flow. Manual cutouts require physical intervention to open or close, often using a lever or cable, making them a cost-effective option for enthusiasts seeking simplicity. Electric cutouts utilize an electronic actuator, allowing drivers to switch exhaust modes via a remote or dashboard switch, providing convenience and precise control over sound and performance.

Performance Benefits of Using Exhaust Cutouts

Exhaust cutouts improve automotive performance by providing a direct path for exhaust gases, reducing backpressure, and enhancing engine efficiency. This modification increases horsepower and torque, allowing for quicker acceleration and improved throttle response. Enthusiasts often install cutouts to switch between a quiet exhaust for daily driving and an aggressive, free-flowing setup for maximum power during spirited driving or racing.

Common Applications of Exhaust Cutouts in Vehicles

Exhaust cutouts are commonly used in performance vehicles to improve exhaust flow and increase horsepower by bypassing restrictive mufflers. They are frequently installed in muscle cars, race cars, and off-road vehicles to enable a switch between quiet street mode and aggressive racing mode. This modification enhances engine efficiency and sound control, making it popular among automotive enthusiasts seeking customizable exhaust performance.

Installation Process for Exhaust Cutouts

Installing an exhaust cutout involves first selecting the appropriate location on the exhaust pipe, typically before the muffler for optimal sound control. The installation process requires cutting a section of the exhaust pipe using a reciprocating saw or pipe cutter, followed by welding or clamping the cutout valve securely in place to ensure an airtight seal. Proper installation ensures enhanced performance and sound customization while maintaining exhaust system integrity.

Legal Considerations for Exhaust Cutout Usage

Exhaust cutouts, devices installed to bypass the muffler and increase engine sound and performance, must comply with local noise regulations and emissions standards to avoid legal penalties. Many jurisdictions mandate specific decibel limits and restrict modifications that increase pollution, making it essential to verify the legality of exhaust cutouts before installation. Consulting local vehicle codes and obtaining necessary permits ensures that exhaust cutout usage does not result in fines, vehicle inspection failures, or warranty voidance.

Popular Cars Featuring Factory or Aftermarket Exhaust Cutouts

Popular cars featuring factory or aftermarket exhaust cutouts include the Ford Mustang GT, Chevrolet Camaro SS, and Dodge Challenger R/T, all known for their performance exhaust systems. These cutouts allow drivers to switch between a quieter, stock exhaust note and a more aggressive, louder sound by bypassing mufflers or resonators. Aftermarket brands like Borla, MagnaFlow, and Flowmaster offer customizable exhaust cutouts that enhance sound control and improve engine performance for muscle cars and sports vehicles.

Exhaust Cutout Maintenance and Troubleshooting Tips

Exhaust cutout maintenance involves regularly inspecting the valve for carbon buildup and ensuring smooth operation of the actuator to prevent exhaust leaks and performance issues. Troubleshooting common problems includes checking electrical connections for the actuator, cleaning or replacing stuck valves, and verifying the control switch functionality. Proper lubrication and timely adjustments help maintain optimal exhaust flow and sound control, enhancing vehicle performance and longevity.

Comparing Exhaust Cutouts to Other Performance Mods

Exhaust cutouts provide a unique advantage by allowing drivers to bypass mufflers for increased exhaust flow, resulting in instant horsepower gains and a more aggressive sound compared to traditional performance mods like cold air intakes or headers. Unlike tuners or ECU remaps that optimize engine parameters, cutouts deliver immediate mechanical changes without altering engine programming. This direct exhaust path improves throttle response and high RPM power, making cutouts a preferred choice for those seeking versatile and reversible performance enhancement.

Real-World Examples: Sound and Power Changes with Exhaust Cutouts

Exhaust cutouts are commonly used in performance vehicles like the Ford Mustang GT and Chevrolet Camaro SS to enhance exhaust flow and sound intensity. When engaged, these cutouts bypass the muffler, producing a louder, more aggressive exhaust note and a measurable increase in horsepower, often around 10-15%. Real-world testing shows improved throttle response and engine efficiency, making exhaust cutouts popular among automotive enthusiasts seeking customizable performance and sound.

example of cutout in exhaust Infographic

samplerz.com

samplerz.com