Detonation in automotive combustion occurs when the air-fuel mixture explodes prematurely inside the engine cylinder. This abnormal combustion causes a sharp spike in pressure, producing a knocking or pinging sound. The phenomenon primarily results from excessive heat or incorrect ignition timing, leading to inefficient engine performance. Engine knock caused by detonation can damage pistons, cylinder walls, and other internal components over time. Modern vehicles use knock sensors to detect detonation and adjust ignition timing accordingly. Proper fuel octane rating and engine tuning help prevent the conditions that lead to detonation, ensuring optimal combustion and engine longevity.

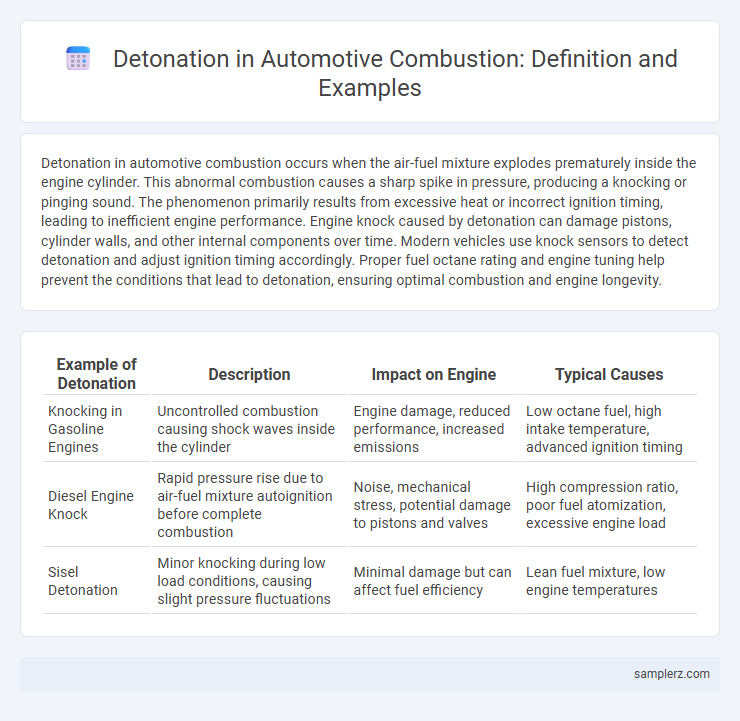

Table of Comparison

| Example of Detonation | Description | Impact on Engine | Typical Causes |

|---|---|---|---|

| Knocking in Gasoline Engines | Uncontrolled combustion causing shock waves inside the cylinder | Engine damage, reduced performance, increased emissions | Low octane fuel, high intake temperature, advanced ignition timing |

| Diesel Engine Knock | Rapid pressure rise due to air-fuel mixture autoignition before complete combustion | Noise, mechanical stress, potential damage to pistons and valves | High compression ratio, poor fuel atomization, excessive engine load |

| Sisel Detonation | Minor knocking during low load conditions, causing slight pressure fluctuations | Minimal damage but can affect fuel efficiency | Lean fuel mixture, low engine temperatures |

Understanding Detonation in Automotive Combustion

Detonation in automotive combustion occurs when the air-fuel mixture in the engine cylinder ignites prematurely, causing shock waves that lead to knocking and engine damage. This abnormal combustion results from excessive pressure and temperature, often influenced by high compression ratios or low-octane fuels. Understanding detonation is crucial for optimizing engine performance and preventing premature wear in internal combustion engines.

Common Causes of Engine Detonation

Engine detonation, also known as knocking, occurs when the air-fuel mixture in a combustion chamber ignites prematurely, causing shock waves that damage engine components. Common causes include using low-octane fuel, excessive engine temperature, incorrect ignition timing, and carbon buildup that increases compression. Effective prevention requires proper fuel selection, maintaining cooling systems, and regular engine tune-ups to minimize risk and enhance performance.

Symptoms Indicating Detonation in Engines

Detonation in combustion engines is characterized by knocking or pinging sounds during acceleration or under load, indicating abnormal combustion. Symptoms include reduced engine performance, increased exhaust gas temperature, and potential engine damage such as piston pitting or cylinder head erosion. Monitoring spark plug condition and fuel quality can help detect early signs of detonation.

Real-World Examples of Engine Detonation

Engine detonation occurs when the air-fuel mixture in a cylinder ignites prematurely, causing knocking that can damage pistons and valves. High-performance turbocharged engines, such as those in rally cars, often experience detonation due to increased cylinder pressures and temperatures. In everyday vehicles, improper fuel octane levels or excessive engine tuning commonly lead to detonation, highlighting the importance of using manufacturer-recommended gasoline to prevent engine damage.

Detonation vs. Pre-Ignition: Key Differences

Detonation in automotive combustion occurs when the air-fuel mixture ignites explosively after the spark, generating shock waves that can damage engine components. Unlike pre-ignition, which ignites the mixture prematurely due to hot spots in the combustion chamber, detonation happens during the combustion process and is characterized by abnormal, high-frequency knocking sounds. Understanding these differences is critical for optimizing engine timing, fuel quality, and preventing severe engine damage in performance and everyday vehicles.

Impact of Detonation on Engine Performance

Detonation in combustion causes abnormal pressure spikes that lead to engine knocking, significantly reducing performance and efficiency. These pressure irregularities damage piston crowns, cylinder walls, and bearings, resulting in decreased engine lifespan. Persistent detonation lowers power output and increases fuel consumption while raising emissions levels in automotive engines.

Fuel Quality and Its Role in Combustion Detonation

Low-quality fuel with insufficient octane rating significantly increases the risk of detonation during combustion, causing premature ignition and engine knocking. High-octane fuels resist auto-ignition under high pressure and temperature conditions, ensuring smoother and more efficient combustion. Fuel additives like anti-knock agents reduce detonation by stabilizing the combustion process and enhancing fuel quality.

How High Temperatures Trigger Detonation

Detonation in automotive combustion occurs when high temperatures cause the air-fuel mixture to autoignite prematurely, leading to shock waves and engine knocking. Temperatures above 500degC in the combustion chamber accelerate fuel vapor ignition before the spark plug's timing, disrupting the normal combustion process. This phenomenon reduces engine efficiency and can cause severe mechanical damage if not controlled through proper ignition timing and fuel quality.

Preventing Detonation in Modern Engines

Detonation in combustion occurs when the air-fuel mixture explodes prematurely, causing engine knocking and potential damage. Preventing detonation in modern engines involves the use of high-octane fuels, precise electronic ignition timing, and advanced knock sensors that adjust combustion parameters in real time. Turbocharged and direct injection engines benefit significantly from these technologies, enhancing engine efficiency and longevity.

Diagnosing Detonation: Tools and Techniques

Detonation in automotive combustion occurs when the air-fuel mixture explodes prematurely, causing engine knock and potential damage. Diagnosing detonation involves tools such as knock sensors, which detect abnormal vibrations, and oscilloscopes that analyze signal patterns for irregular combustion events. Advanced techniques include combustion pressure analysis and exhaust gas monitoring to pinpoint the intensity and frequency of detonation, ensuring precise engine tuning and durability.

example of detonation in combustion Infographic

samplerz.com

samplerz.com