In the automotive industry, a puck in bushing serves as a critical component that enhances vehicle suspension systems by reducing vibrations and providing cushioning between metal parts. These pucks are typically made from durable rubber or polyurethane materials, which absorb shocks and prevent metal-to-metal contact in control arms and stabilizer bars. This design improves ride comfort and extends the lifespan of suspension components by mitigating wear and tear. Pucks in bushings are essential for maintaining proper alignment and handling of a vehicle, contributing to safer driving dynamics. Engineers often select specific puck sizes and materials based on vehicle weight, intended use, and environmental conditions. Data from durability tests show that high-quality pucks significantly reduce noise, vibration, and harshness (NVH), making them indispensable in modern automotive suspension engineering.

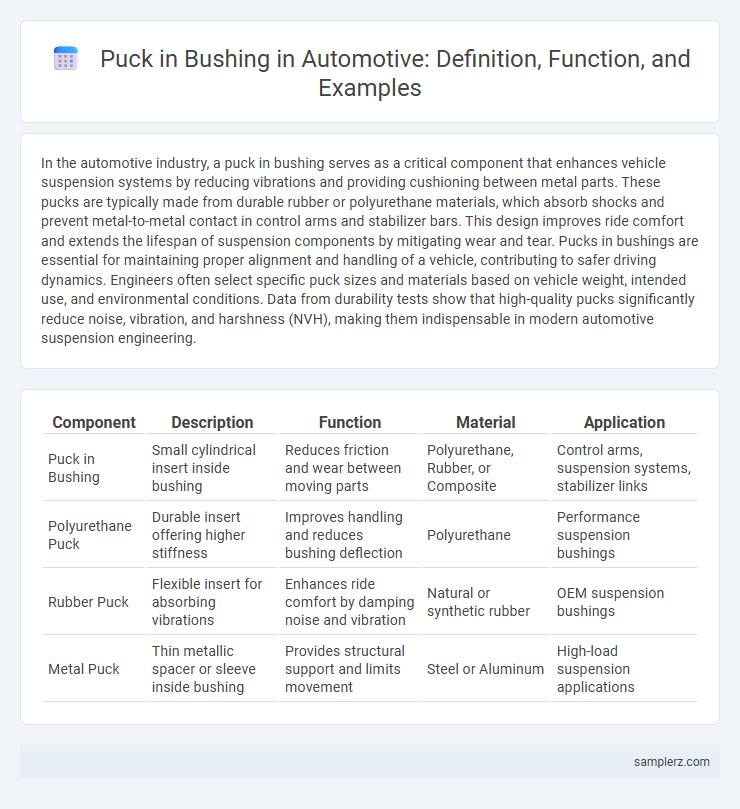

Table of Comparison

| Component | Description | Function | Material | Application |

|---|---|---|---|---|

| Puck in Bushing | Small cylindrical insert inside bushing | Reduces friction and wear between moving parts | Polyurethane, Rubber, or Composite | Control arms, suspension systems, stabilizer links |

| Polyurethane Puck | Durable insert offering higher stiffness | Improves handling and reduces bushing deflection | Polyurethane | Performance suspension bushings |

| Rubber Puck | Flexible insert for absorbing vibrations | Enhances ride comfort by damping noise and vibration | Natural or synthetic rubber | OEM suspension bushings |

| Metal Puck | Thin metallic spacer or sleeve inside bushing | Provides structural support and limits movement | Steel or Aluminum | High-load suspension applications |

Understanding Pucks in Bushings: An Automotive Overview

Pucks in bushings serve as critical cushioning elements within automotive suspension systems, designed to absorb shocks and reduce vibrations between metal components. Typically made from polyurethane or rubber, these pucks enhance vehicle stability by maintaining proper alignment and minimizing wear on suspension parts. Understanding the material composition and placement of pucks is essential for optimizing ride quality and extending the lifespan of automotive bushings.

Key Functions of Puck Bushings in Vehicle Suspension

Puck bushings in vehicle suspension systems play a crucial role in absorbing shocks and vibrations to enhance ride comfort and handling stability. These components isolate and cushion the interface between suspension arms and chassis, reducing noise and wear while maintaining precise wheel alignment. Their durability and flexibility improve overall vehicle performance by managing dynamic loads during acceleration, braking, and cornering.

Common Types of Puck Bushings Used in Cars

Common types of puck bushings used in cars include rubber, polyurethane, and composite materials, each designed to provide specific advantages in vibration isolation and durability. Rubber puck bushings offer excellent noise reduction and flexibility, making them ideal for comfort-oriented vehicles, while polyurethane puck bushings provide increased stiffness and wear resistance, favored in performance and off-road applications. Composite puck bushings combine lightweight properties with high strength, enhancing handling precision and longevity in modern automotive suspension systems.

Example Applications of Puck-in-Bushing Designs

Puck-in-bushing designs are widely utilized in automotive suspension systems to improve vibration isolation and enhance ride comfort by securely housing the puck within the bushing sleeve. This configuration is commonly applied in control arms, stabilizer bars, and shock absorbers, enabling precise load distribution and reducing metal-to-metal contact. Manufacturers often select puck-in-bushing assemblies for their durability and ability to maintain vehicle alignment under dynamic driving conditions.

Advantages of Puck Bushings for Automotive Performance

Puck bushings in automotive suspensions provide enhanced vibration and noise reduction by isolating shocks more effectively than traditional bushings. Their compact, cylindrical design allows for increased durability and flexibility, improving handling precision and overall vehicle stability. These advantages contribute to a smoother ride and extended suspension component lifespan, essential for high-performance and off-road vehicles.

Puck Bushings vs. Traditional Bushings: A Comparison

Puck bushings, composed of dense polyurethane, offer enhanced durability and resistance to wear compared to traditional rubber bushings commonly used in automotive suspensions. These puck bushings provide superior load-bearing capacity and improved vibration damping, resulting in better handling precision and reduced noise transmission. Unlike traditional bushings, their modular design allows for easier maintenance and replacement, optimizing vehicle performance and longevity.

Materials Commonly Used in Puck Bushings

Puck bushings in automotive applications commonly utilize materials such as high-density polyurethane, rubber composites, and thermoplastic elastomers for optimal durability and vibration isolation. Polyurethane offers excellent resistance to wear, oil, and temperature variations, making it ideal for suspension components. Rubber blends provide superior flexibility and noise dampening, ensuring smoother vehicle operation and enhanced comfort.

Signs of Wear in Puck Bushings: Automotive Indicators

Signs of wear in puck bushings include increased vibration, unusual noise, and visible cracks or deformation around the bushing surface. These indicators often suggest deterioration due to constant friction and load stress in automotive suspension systems. Early detection of puck bushing wear can prevent alignment issues and maintain vehicle stability.

Installation Process for Puck Bushings in Vehicles

The installation process for puck bushings in vehicles involves precise alignment of the puck within the suspension bushing housing to ensure optimal cushioning and vibration isolation. Technicians often use specialized presses and alignment tools to insert the puck securely without damaging the rubber or polyurethane material. Proper installation enhances suspension performance, reduces wear on control arms, and improves overall vehicle handling and ride comfort.

Maintenance Tips for Extending Puck Bushing Lifespan

Regular inspection of puck bushings for wear and tear is crucial to prevent premature failure in automotive suspension systems. Applying high-quality lubricants reduces friction and minimizes material degradation, significantly extending the bushing's operational life. Ensuring proper installation torque and alignment helps maintain puck bushing performance and avoids uneven stress distribution that can shorten lifespan.

example of puck in bushing Infographic

samplerz.com

samplerz.com