In the automotive industry, a "banana" shape in a trailing arm refers to its curved or arched design, resembling the shape of a banana. This design enhances suspension performance by providing better clearance around other components and improving the arm's structural strength. Trailing arms with a banana shape are commonly used in multi-link suspension systems to optimize wheel alignment and vehicle handling. The banana-shaped trailing arm allows for precise control of wheel movement and reduces unwanted flex during driving. It contributes to improved ride comfort and stability by maintaining proper suspension geometry under various load conditions. Manufacturers often select this design to balance durability, weight, and overall suspension efficiency in passenger cars and high-performance vehicles.

Table of Comparison

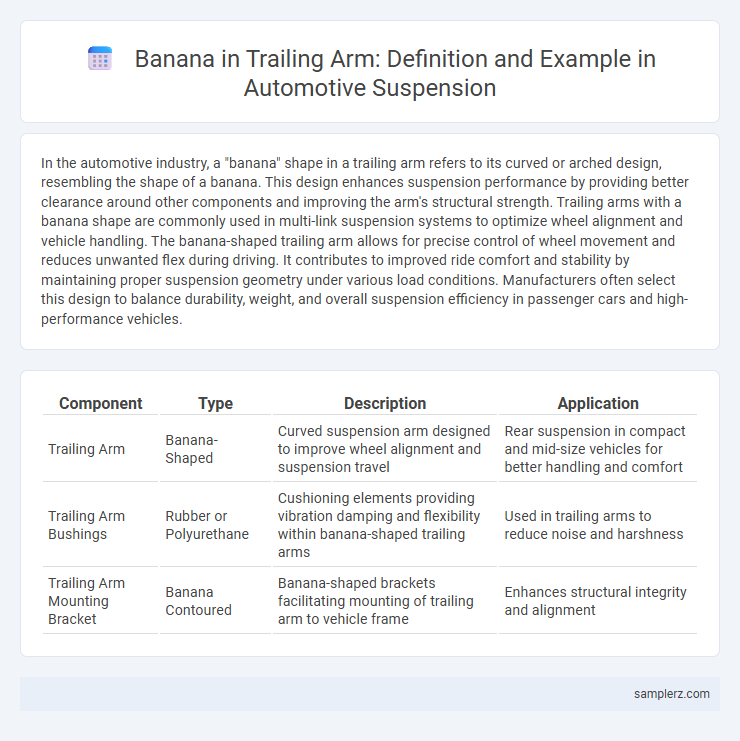

| Component | Type | Description | Application |

|---|---|---|---|

| Trailing Arm | Banana-Shaped | Curved suspension arm designed to improve wheel alignment and suspension travel | Rear suspension in compact and mid-size vehicles for better handling and comfort |

| Trailing Arm Bushings | Rubber or Polyurethane | Cushioning elements providing vibration damping and flexibility within banana-shaped trailing arms | Used in trailing arms to reduce noise and harshness |

| Trailing Arm Mounting Bracket | Banana Contoured | Banana-shaped brackets facilitating mounting of trailing arm to vehicle frame | Enhances structural integrity and alignment |

Understanding the "Banana" Shape in Trailing Arm Design

The "banana" shape in trailing arm design enhances suspension flexibility while maintaining structural integrity, crucial for vehicle stability and ride comfort. This curved geometry allows for better wheel articulation and load distribution during cornering and uneven terrain navigation. Automakers integrate this design to optimize handling dynamics and reduce stress concentrations in the suspension system.

History of Banana-Style Trailing Arms in Automotive Engineering

Banana-style trailing arms, recognized for their curved design that enhances suspension travel and improves vehicle stability, emerged prominently in automotive engineering during the 1960s. Pioneered by racing teams seeking better weight distribution and handling dynamics, this design allowed for superior control in both street and track environments. Over time, manufacturers integrated banana trailing arms into performance and off-road vehicles, leveraging their ability to reduce squat and improve traction under acceleration.

Advantages of Banana Trailing Arms in Suspension Systems

Banana trailing arms in automotive suspension systems enhance vehicle stability by providing improved articulation and flexibility, which helps absorb road shocks more effectively. Their curved design allows for optimized wheel alignment and reduces stress on suspension components, resulting in increased durability and smoother ride quality. These arms also contribute to better handling and cornering performance by maintaining consistent tire contact with the road surface.

Common Vehicles Featuring Banana Trailing Arms

Common vehicles featuring banana trailing arms include models like the Honda Civic, Toyota Corolla, and Ford Focus, where these components enhance suspension stability and ride comfort. The banana-shaped trailing arm design improves wheel alignment and reduces lateral movement during cornering, contributing to better handling performance. Automotive manufacturers often incorporate banana trailing arms in compact and midsize cars for optimized suspension geometry and durability.

Structural Functionality of Banana-Shaped Trailing Arms

Banana-shaped trailing arms enhance structural functionality by providing improved load distribution and increased torsional stiffness compared to straight trailing arms. Their curved design allows for better absorption of lateral forces and optimized suspension geometry, resulting in enhanced vehicle stability and ride comfort. This structural form also minimizes stress concentrations, contributing to longer component durability in automotive suspension systems.

Comparison: Banana vs Straight Trailing Arm Designs

Banana trailing arms offer enhanced suspension geometry by allowing greater wheel travel and improved camber control compared to straight trailing arm designs, which often result in limited articulation and harsher ride quality. The curved shape of banana arms reduces unsprung weight and stress concentrations, promoting better handling and durability in off-road and performance vehicles. In contrast, straight trailing arms provide simpler manufacturing and lower costs but sacrifice the refined dynamic response found in banana-style setups.

Impact of Banana Trailing Arms on Ride Comfort and Handling

Banana trailing arms, curved suspension components commonly used in automotive rear-wheel setups, significantly enhance ride comfort by absorbing road irregularities more effectively than straight arms. Their unique shape helps maintain optimal wheel alignment during suspension travel, improving vehicle handling and stability in dynamic driving conditions. This design reduces vibrations and lateral forces, resulting in smoother cornering and better overall control.

Material Choices for Banana Trailing Arm Construction

Banana trailing arms are often constructed using high-strength steel alloys and aluminum to balance durability and weight reduction in automotive suspension systems. Advanced composites such as carbon fiber reinforced polymers increasingly enhance performance by offering superior stiffness and corrosion resistance. Material selection directly influences the trailing arm's impact on ride quality, handling precision, and overall vehicle longevity in dynamic driving conditions.

Maintenance and Durability of Banana Trailing Arms

Banana trailing arms in automotive suspension systems require regular inspection for wear and tear to ensure optimal maintenance and durability. Using high-quality materials like forged steel enhances the lifespan and resistance to corrosion, reducing the frequency of replacements. Proper lubrication of bushings and joints prevents premature failure and maintains smooth suspension performance over extended mileage.

Future Trends: Evolving Designs of Banana-Shaped Trailing Arms

Advancements in banana-shaped trailing arm designs focus on lightweight materials such as high-strength aluminum alloys and carbon fiber composites to enhance vehicle handling and fuel efficiency. Integration of adaptive suspension technologies with these trailing arms offers improved ride comfort and dynamic response by actively adjusting to road conditions. Future trends also emphasize modularity for easier maintenance and compatibility with electric and autonomous vehicles, reflecting evolving automotive engineering demands.

example of banana in trailing arm Infographic

samplerz.com

samplerz.com