Knock in combustion engines refers to the abnormal ignition of the air-fuel mixture within the cylinder, causing a sharp knocking or pinging sound. This phenomenon occurs when the mixture auto-ignites before the spark plug fires, leading to pressure spikes that can damage engine components. Common causes of knock include low-octane fuel, high engine temperature, and incorrect ignition timing. Automotive manufacturers monitor knock through sensors that detect vibrations and pressure fluctuations inside the cylinder. Data from knock sensors enable engine control units to adjust ignition timing and fuel delivery to prevent damage. Managing knock is critical for optimizing engine performance, improving fuel efficiency, and extending engine life.

Table of Comparison

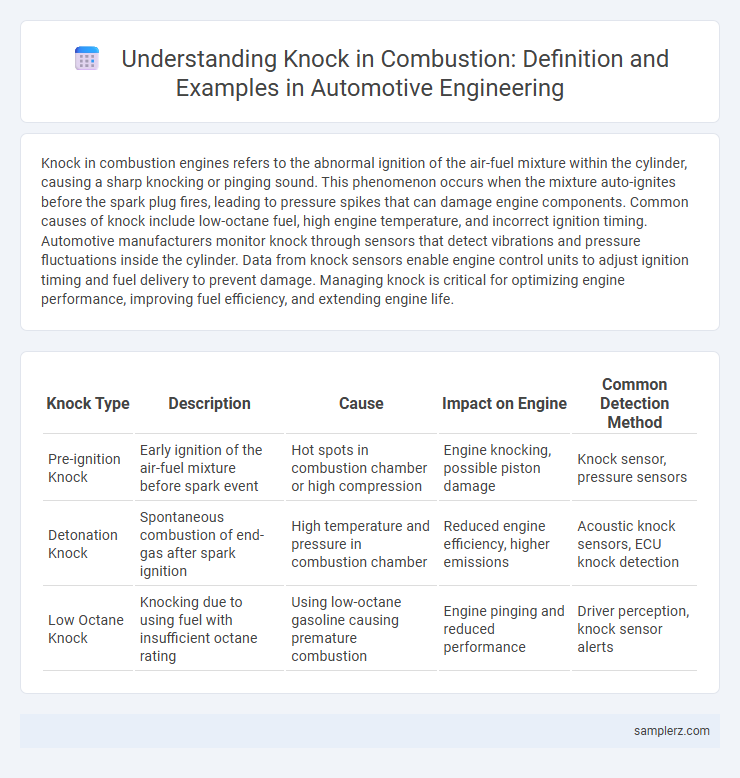

| Knock Type | Description | Cause | Impact on Engine | Common Detection Method |

|---|---|---|---|---|

| Pre-ignition Knock | Early ignition of the air-fuel mixture before spark event | Hot spots in combustion chamber or high compression | Engine knocking, possible piston damage | Knock sensor, pressure sensors |

| Detonation Knock | Spontaneous combustion of end-gas after spark ignition | High temperature and pressure in combustion chamber | Reduced engine efficiency, higher emissions | Acoustic knock sensors, ECU knock detection |

| Low Octane Knock | Knocking due to using fuel with insufficient octane rating | Using low-octane gasoline causing premature combustion | Engine pinging and reduced performance | Driver perception, knock sensor alerts |

Understanding Knock: Definition and Causes in Combustion

Knock in combustion occurs when the air-fuel mixture ignites prematurely or unevenly in the engine cylinder, resulting in a sharp knocking noise and potential engine damage. This abnormal combustion is primarily caused by factors such as high cylinder temperature, excessive pressure, or low octane fuel, which lead to uncontrolled and rapid pressure spikes. Understanding knock involves analyzing ignition timing, engine load, and fuel characteristics to optimize performance and prevent engine knock-related damage.

Typical Symptoms of Engine Knock in Automotive Engines

Engine knock in automotive engines is characterized by a distinct metallic pinging or rattling sound during combustion, often most noticeable under acceleration or load. Typical symptoms include reduced engine performance, increased fuel consumption, and noticeable vibrations or rough idling. Persistent knocking can lead to severe engine damage, such as piston wear and compromised cylinder integrity.

Real-World Example: Knock Detected in Gasoline Engines

Knock in combustion occurs when the air-fuel mixture in gasoline engines detonates prematurely, causing a sharp rise in cylinder pressure that can damage engine components. A real-world example is seen in high-performance turbocharged engines, where low-octane fuel or excessive engine load leads to knock, detected by knock sensors that trigger ignition timing adjustments. Effective knock control improves engine efficiency and prevents costly repairs by maintaining optimal combustion stability.

The Role of Fuel Quality in Combustion Knock

Fuel quality significantly influences combustion knock by affecting the octane rating, which determines resistance to premature detonation in engines. Low-octane fuels ignite too early under compression, causing knocking that damages engine components and reduces efficiency. High-performance engines rely on premium fuels with higher octane numbers to maintain smooth combustion and optimize power output.

Engine Design Factors Contributing to Knock

Engine design factors contributing to knock include high compression ratios, which increase the temperature and pressure inside the cylinder, promoting premature fuel ignition. Spark timing that is too advanced can also cause the air-fuel mixture to ignite before the piston reaches the optimal position, leading to knocking. Additionally, inadequate cooling systems fail to maintain optimal cylinder temperatures, raising the risk of knock during combustion.

Case Study: Knock in Turbocharged versus Naturally Aspirated Engines

Knock in turbocharged engines often occurs at higher pressures and temperatures due to forced induction, causing more intense detonation compared to naturally aspirated engines. A case study revealed that turbocharged engines require advanced knock sensors and precise ignition timing controls to manage knock effectively, preventing engine damage. Naturally aspirated engines display knock at lower load conditions and benefit from simpler management strategies, highlighting the importance of engine design in combustion stability.

Detection Technologies for Knock in Modern Vehicles

Modern vehicles employ advanced detection technologies such as piezoelectric knock sensors and ionization sensors to identify engine knock with high precision. These sensors monitor vibrations and combustion patterns in real-time to detect abnormal pressure waves indicative of knock events. Integration with engine control units (ECUs) allows immediate adjustments in ignition timing and fuel injection to prevent knock, ensuring optimal engine performance and longevity.

The Impact of Knock on Engine Performance and Longevity

Knock in combustion engines occurs when fuel-air mixtures ignite prematurely, causing excessive pressure spikes that damage piston surfaces and cylinder walls. This abnormal combustion leads to reduced engine efficiency, increased fuel consumption, and a significant drop in power output. Persistent knocking accelerates wear and tear, shortening engine longevity and increasing maintenance costs.

Preventive Measures: How to Reduce Knock in Combustion

To reduce knock in combustion, maintain high-octane fuel to resist premature ignition and optimize spark timing to ensure the air-fuel mixture burns correctly. Implement advanced engine knock sensors and electronic control units (ECUs) to detect and adjust engine parameters in real-time. Improving cooling systems and using direct fuel injection also help lower combustion temperatures, minimizing the risk of knock.

Future Trends: Innovations to Eliminate Engine Knock

Emerging technologies like advanced ion-sensing knock control and machine learning algorithms enable real-time detection and adjustment of combustion parameters to prevent engine knock. Innovations in fuel additives and alternative fuels, such as hydrogen-enriched gasoline, contribute to smoother combustion and reduced knocking tendencies. Development of predictive engine management systems integrates AI with high-precision sensors to optimize ignition timing and enhance engine efficiency while eliminating knock.

example of knock in combustion Infographic

samplerz.com

samplerz.com